Computerized Tomography (CT) image uniformization metal artifact correction method based on four-order total-variation shunting

A fourth-order full-variable shunt and CT image technology, applied in image enhancement, image data processing, instruments, etc., can solve problems such as complex operation, large amount of calculation, and difficulty in practical application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The technical solution of the present invention will be described in detail below in conjunction with specific embodiments of the accompanying drawings.

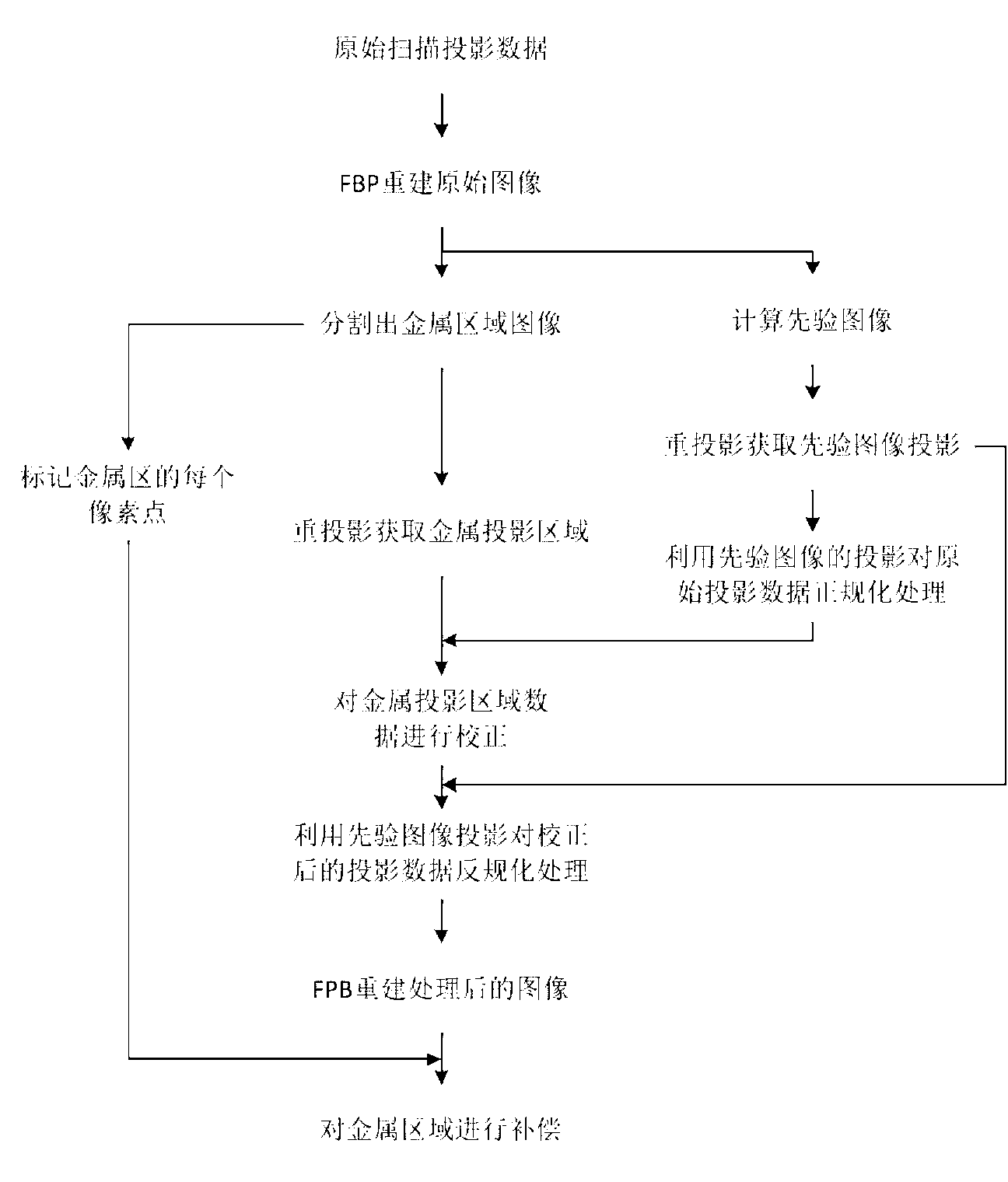

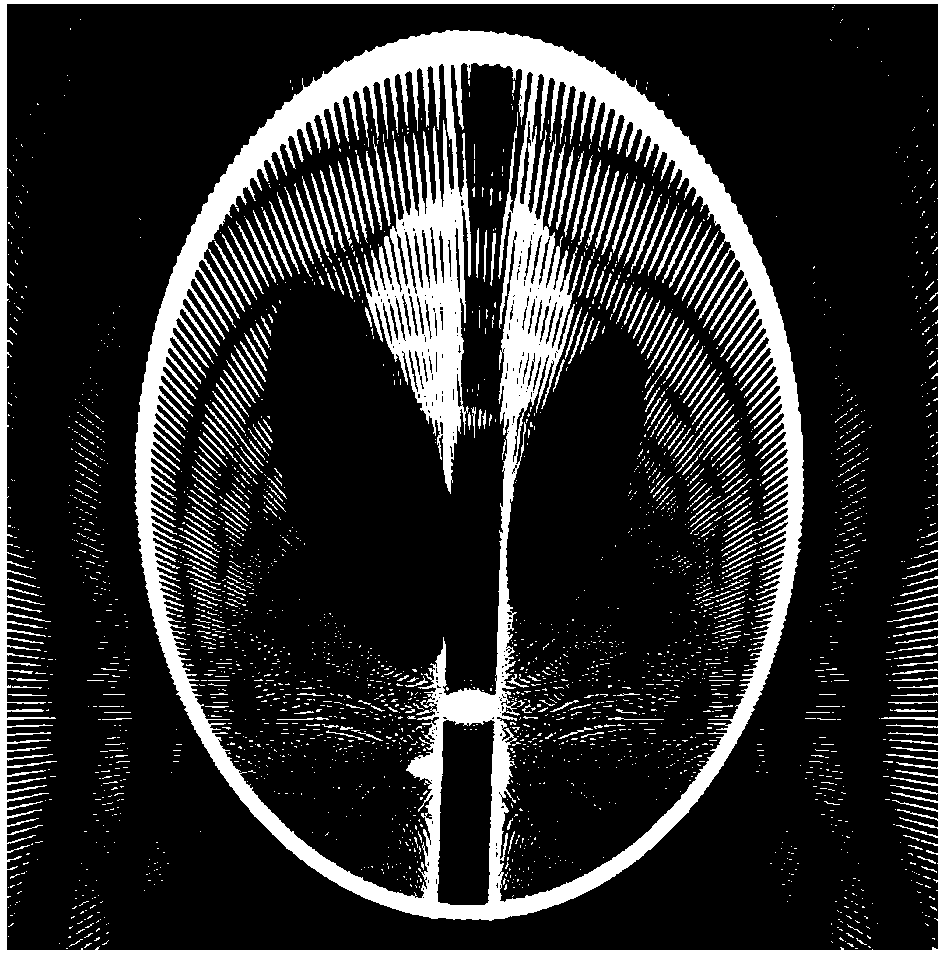

[0058] refer to figure 1 Introduce the main steps of the present invention:

[0059] Step 1, raw scan data collection

[0060] The rotating table is controlled by software to rotate at a small angle, generally not more than 1°, and the micro-computed tomography system collects 360° biological projection data. Use the preprocessing software to perform compensation for bad points and bad lines, bright field and dark field correction, and geometric correction preprocessing on the computer tomography projection data, and then obtain the sinogram g(m,n),m=1,...M,n=1, ...N, M is the total number of detectors, N is the total number of projection angles.

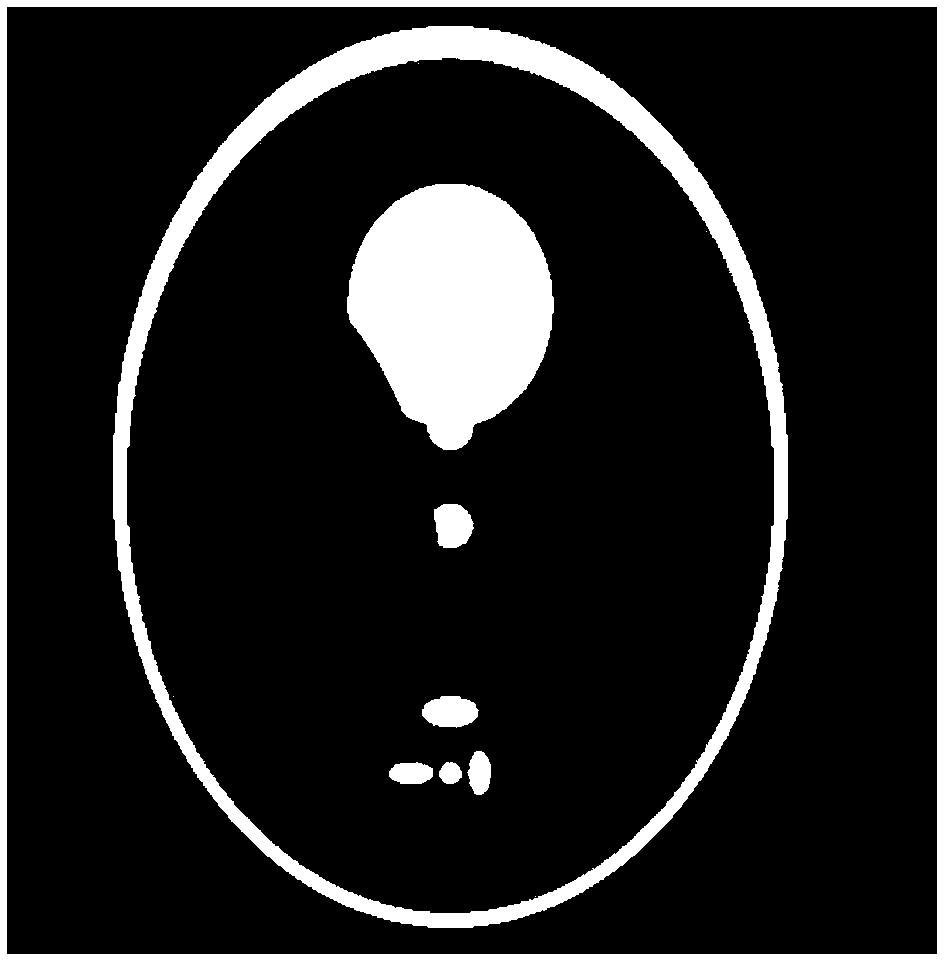

[0061] Step 2, Determine the metal area

[0062] Using the fan beam projection data g(m,n) obtained in step 1, directly reconstruct the projection data with FBP to obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com