Forging Hydraulic Control Method Based on Double Monitoring System

A monitoring system and control method technology, applied in the field of hydraulic presses, can solve the problems of large power grid impact, low-voltage motor power, and large floor space, and achieve the effects of convenient implementation, improved working accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

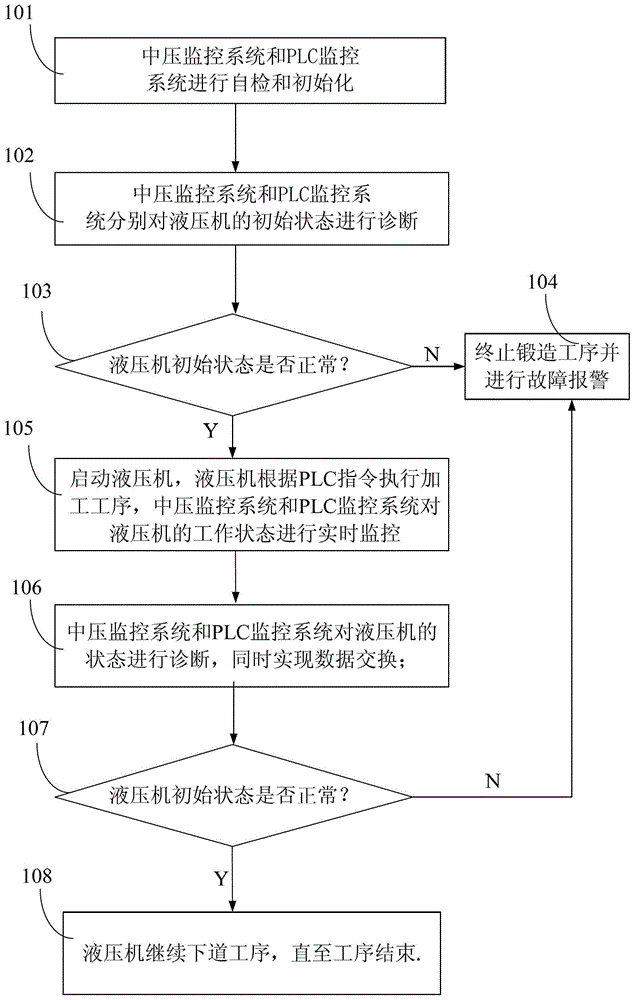

[0016] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0017] See figure 1 , in order to improve the safety performance of the forging hydraulic press, the present invention uses a dual monitoring system to monitor the forging hydraulic press in real time, wherein: the above-mentioned dual monitoring system is composed of a medium-voltage monitoring system and a PLC monitoring system; the above-mentioned medium-voltage monitoring system is a comprehensive relay protection device ; The concrete technical scheme of this specific embodiment is:

[0018] A forging hydraulic control method based on a double monitoring system, comprising the following steps:

[0019] Step 101, the medium voltage monitoring system and the PLC monitoring system perform self-inspection and initialization;

[0020] Step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com