A reciprocating fretting friction and wear testing machine

A wear test, fretting friction technology, applied in the direction of testing wear resistance, etc., can solve the problems of inability to achieve automatic control, limited use, complex structure, etc., to achieve simple structure, wide frequency variation range, and small equipment volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further elaborated below in conjunction with the accompanying drawings.

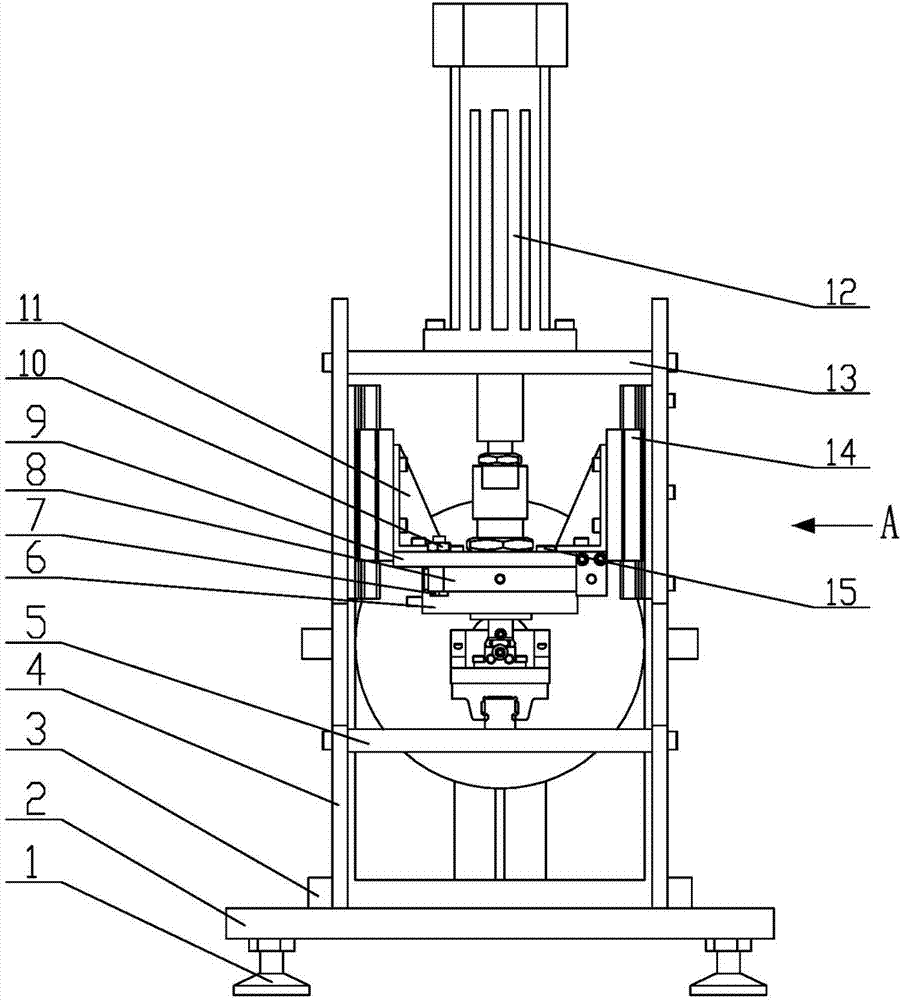

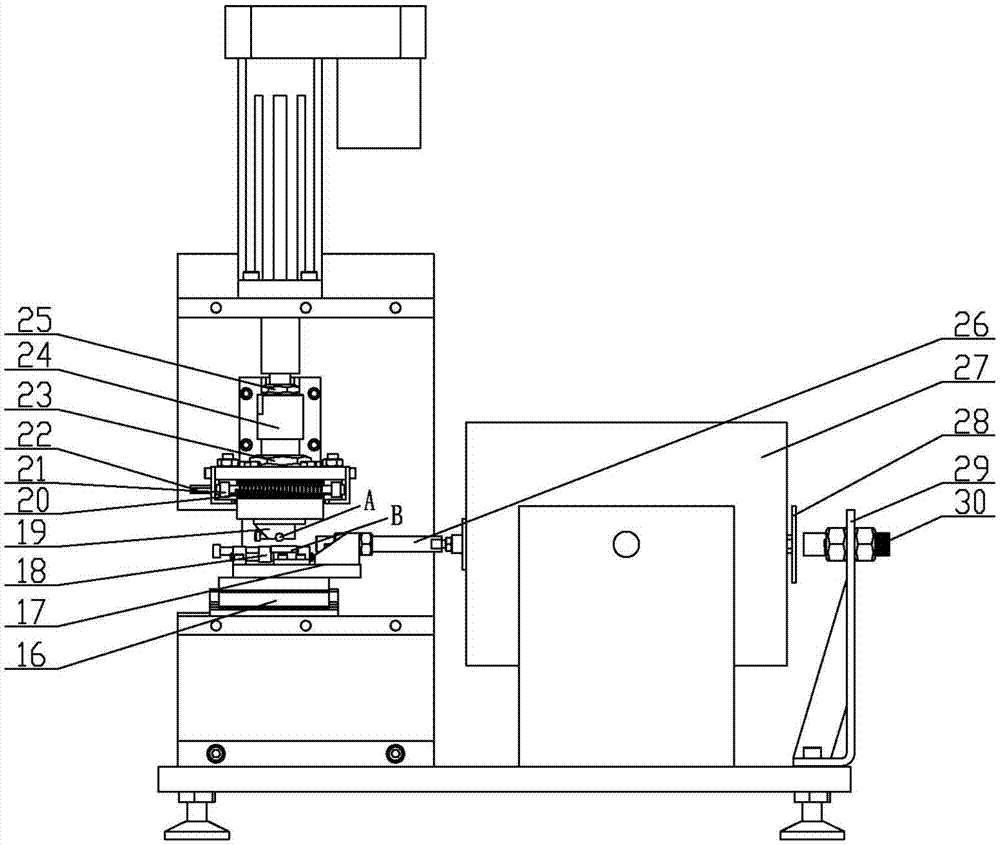

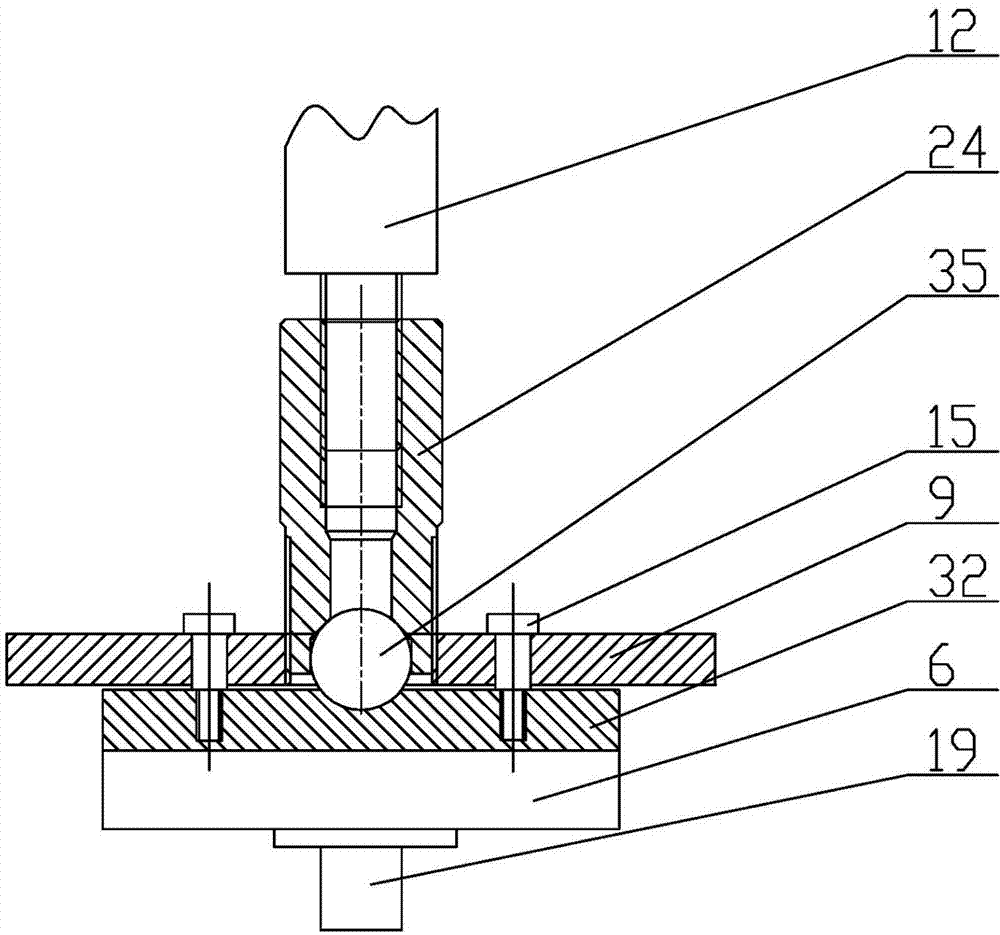

[0026] refer to figure 1 and figure 2 As shown, one embodiment of the present invention is a reciprocating fretting friction and wear testing machine, the testing machine includes a base plate 2 and a bracket placed on the base plate 2, a driving device, a loading device, a positioning clamping device, a signal conditioning As for the data acquisition device, the bracket is at least composed of two side plates 4 longitudinally fixed on the bottom plate 2, and at least a lower rail seat 5 and a top cylinder seat 13 are installed between the two side plates 4;

[0027] The driving device at least includes a power source component, a slide table 17 and a linear guide rail 16, the power source component is connected to the slide table 17 in power, the slide table 17 is connected with the slide block on the linear guide rail 16, and the linear guide rail 16 is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com