A method and device for measuring the velocity and frequency of ultrasonic traveling waves in liquid

An ultrasonic and ultrasonic technology, which is used in measuring devices, measuring ultrasonic/sonic/infrasonic waves, and measuring propagation speed, etc., can solve the problems of cumbersome operation and adjustment process and high requirements for ultrasonic grating imaging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

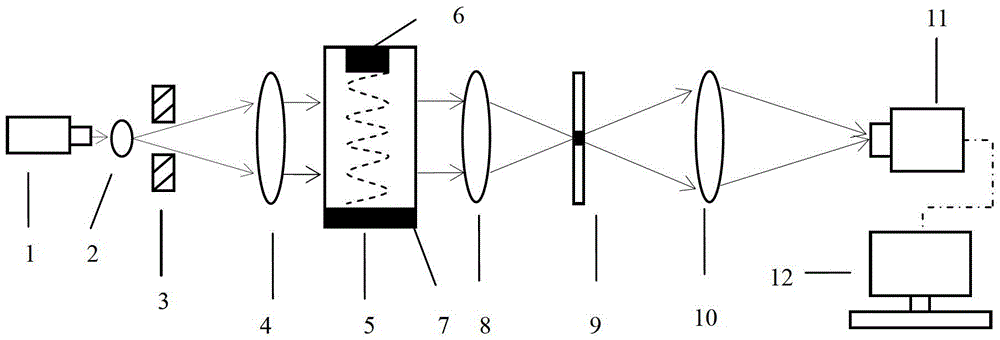

[0085] The device provided in this embodiment is used to measure the wavelength of ultrasonic waves. Such as figure 1As shown, it includes light source 1, beam expander lens 2, diaphragm 3, collimator lens 4, transparent water tank 5, ultrasonic transducer 6, sound-absorbing medium 7, lens 8, amplitude filter 9, imaging lens 10, area array Photodetector 11 and computer 12; light source 1, beam expander lens 2, diaphragm 3, collimating lens 4, transparent water tank 5, lens 8, amplitude filter 9, imaging lens 10 and area array photodetector 11 along the light beam The forward direction is arranged in sequence, the ultrasonic transducer 6 and the sound-absorbing medium 7 are respectively located on both sides parallel to the light beam inside the transparent water tank 5 , and the area array photodetector 11 is connected to the computer 12 . Wherein, the light source 1 can be a monochromatic light source or an ordinary low-power laser, such as a mercury lamp, a sodium lamp, a h...

Embodiment 2

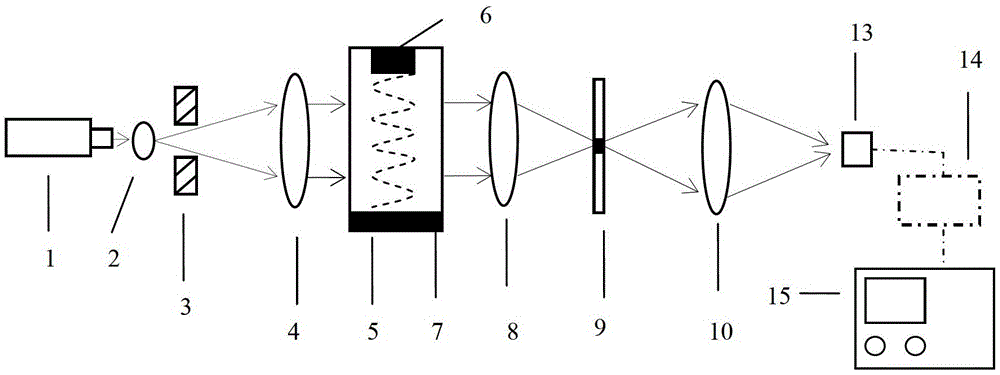

[0092] This embodiment is used to measure the wavelength and frequency of ultrasound. use as figure 2 The shown device comprises a light source 1, a beam expander lens 2, a diaphragm 3, a collimating lens 4, a transparent water tank 5, an ultrasonic transducer 6, an acoustic medium 7, a lens 8, an amplitude filter 9, and an imaging lens 10. Photodetector 13 with a small hole (photodetector with a sufficiently large response frequency with a small hole), amplifying circuit 14 and oscilloscope 15; light source 1, beam expander lens 2, diaphragm 3, collimating lens 4, transparent The water tank 5, the lens 8, the amplitude filter 9, the imaging lens 10, and the photodetector 13 with a small hole are arranged in sequence along the direction of light beam advancement, and the photodetector 13 with a small hole is placed on the measuring fine-tuning seat, and the The photodetector 13, the amplifying circuit 14 and the oscilloscope 15 are connected in sequence, and the ultrasonic t...

Embodiment 3

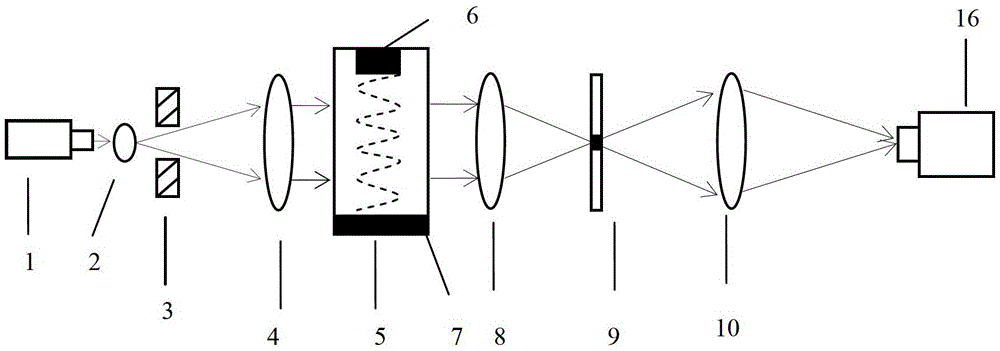

[0098] The device provided in this embodiment can be used to measure the wavelength of ultrasonic waves. Its constituent parts and the arrangement among them are roughly the same as the device provided in Embodiment 1, except that it does not include a computer 12 and uses a micrometer eyepiece 16 instead of an area array photodetector 11 . The light source 1 can be a monochromatic light source or an ordinary low-power laser, such as a mercury lamp, a sodium lamp, a helium-neon laser, a semiconductor laser diode, etc., and the beam emitted by it passes through the beam expander 2, the aperture 3, and the collimating mirror 4 to output a uniform Parallel light is projected onto the traveling wave ultrasonic grating generated by the ultrasonic transducer 6 and the sound-absorbing medium 7, and passes through the lens 8 to form the spectrum of the ultrasonic grating, which is processed by the amplitude filter 9 and then the spectral image of the grating is obtained by the imaging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com