Automatic robot hearth opening and blocking device

A robot and furnace eye technology, applied in the field of smelting equipment, can solve the problems of inconvenient disassembly and replacement of eye plugging tools, poor fluidity, complex structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

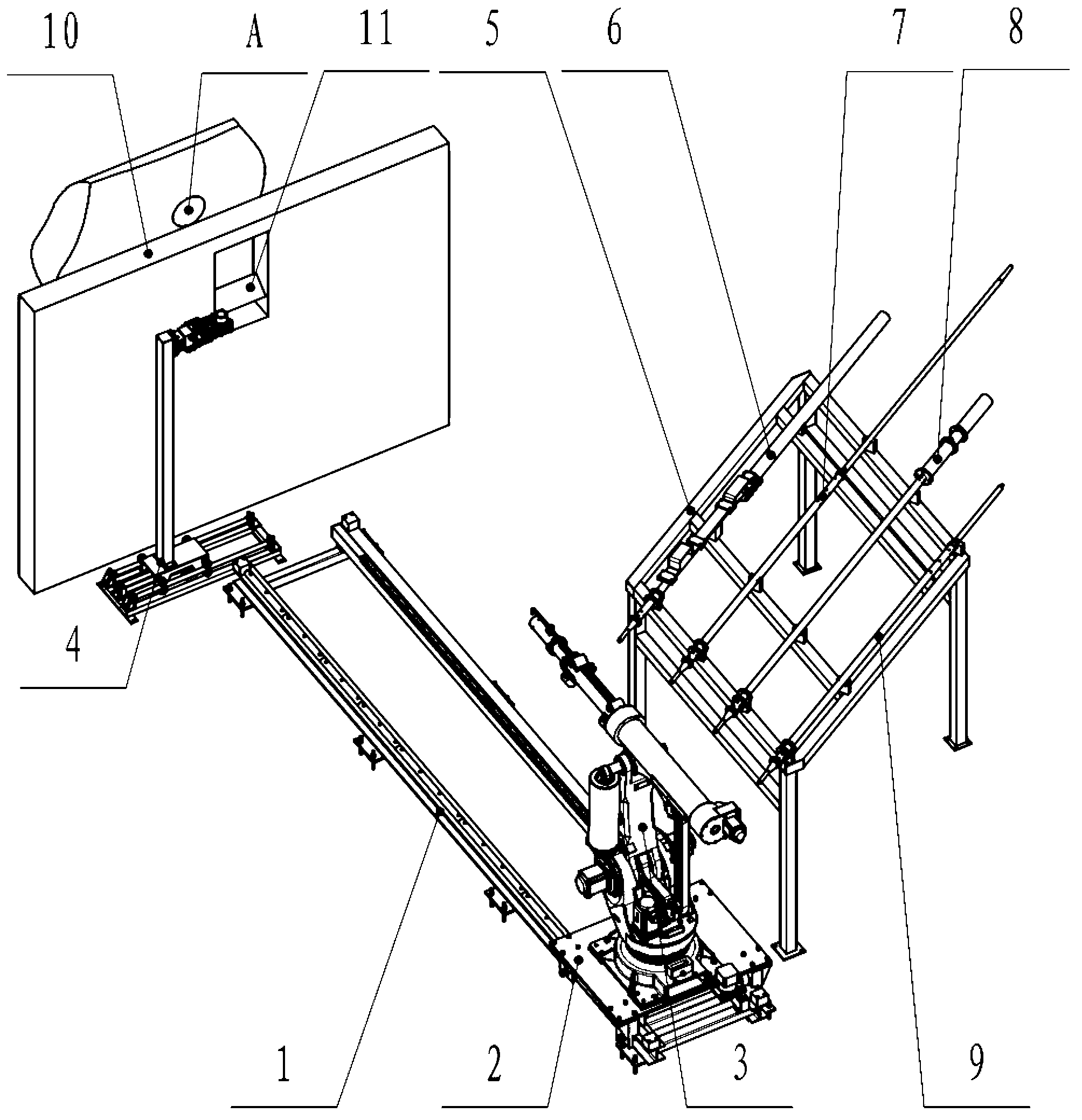

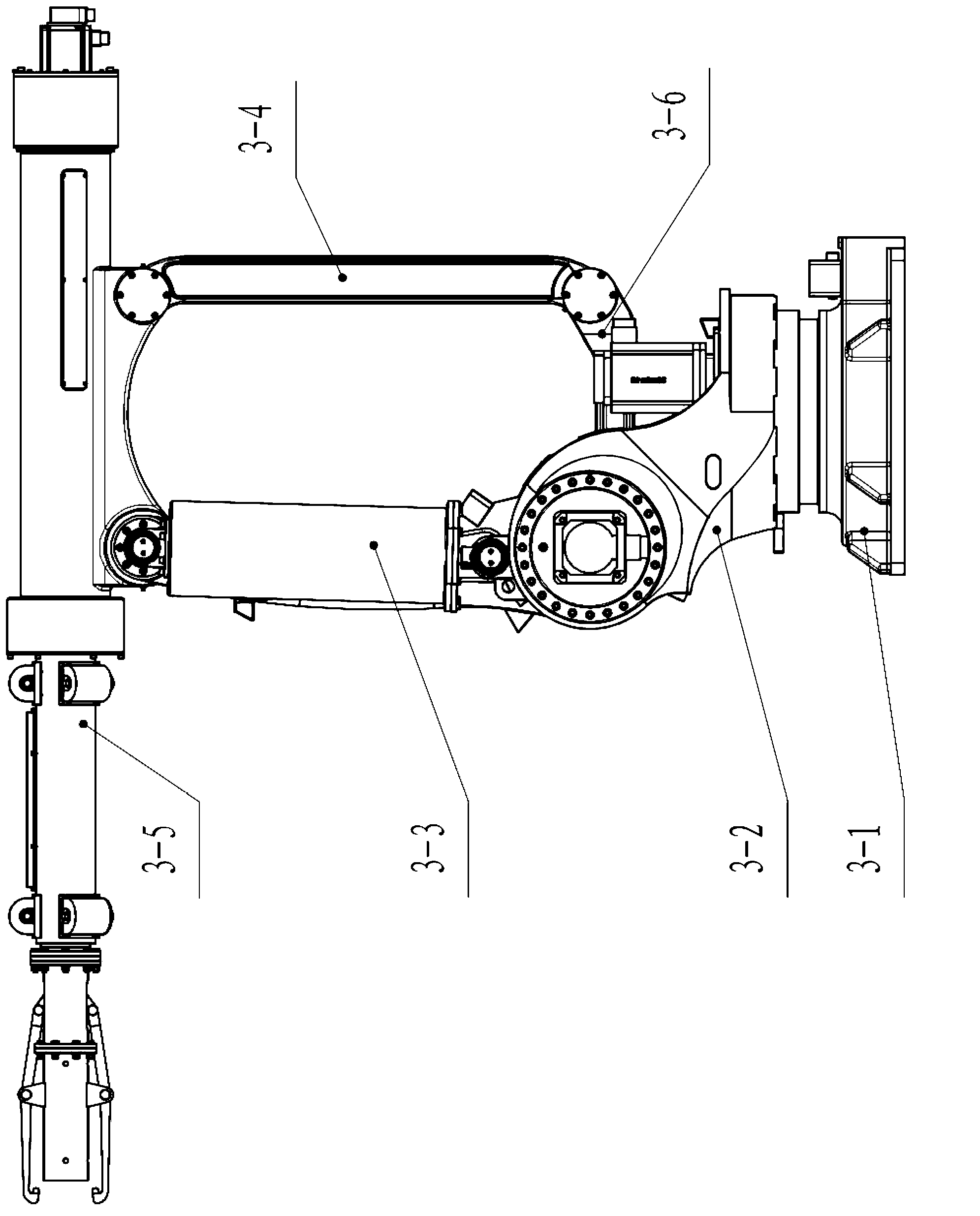

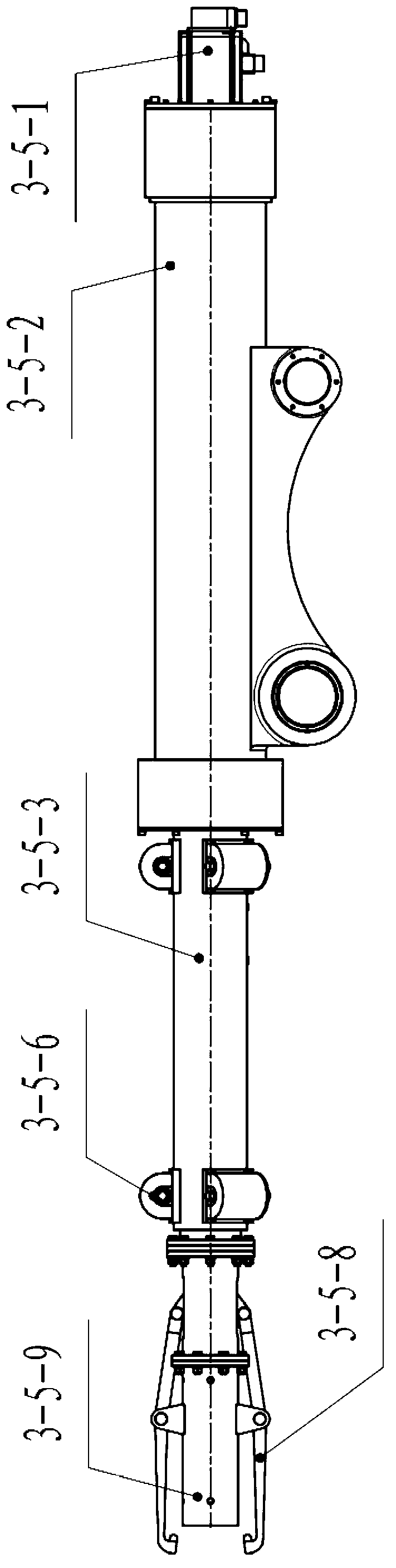

[0040] The specific embodiment of the present invention sees Figure 1 to Figure 18 , a robot automatic unblocking furnace hole device, which includes a guide rail (1), a mobile base (2), a special robot (3), a cable transfer mechanism (4), a combined tool rack (5), and a heat shield (10) , wherein the guide rail (1) is arranged on the ground along the axial direction of the furnace eye (A), a heat shield (10) is provided between the furnace eye (A) and the guide rail (1), and the mobile base (2) can move along the guide rail (1) For forward and backward movement, a special robot (3) is provided on the mobile base (2), and a cable transfer mechanism (4) is provided on the left side of the front end of the guide rail (1), and the cable transfer mechanism (4) is located on the heat shield (10 ), the rear end right side of the guide rail (1) is provided with a combination tool rack (5).

[0041] Four kinds of tools are placed on the combined tool rack (5), including a burner (6)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com