Method for determining a fluid flow rate with a fluid control valve

A valve and flow technology, applied in one field of one, can solve the problems of the influence of the measurement accuracy of the flowmeter, the increase in maintenance costs, and the difficulty of installing the flowmeter, so as to achieve low cost, reduced operating costs, operating efficiency and reliability. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0059] The preferred implementation method of the novel regulating valve measuring flow comprises the following steps:

[0060] 1) Provide the above-mentioned new type of regulating valve, including valve body, actuator, controller and differential pressure sensor; the controller is a chip set, including circuit board, microprocessor, memory, input and output modules and auxiliary components connected element;

[0061] 2) Provide the flow characteristic curve of the valve body, the flow characteristic curve refers to the relationship between the relative flow and the relative opening under the condition of keeping the pressure difference between the two ends of the valve constant;

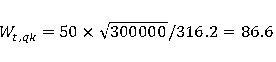

[0062] 3) Provide the flow coefficient of the valve body, which is a physical quantity to measure the flow control capability of the valve;

[0063] 4) Provide the adjustable ratio of the valve body, the adjustable ratio is the ratio of the maximum flow to the minimum flow that the valve can contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com