Vibration isolation device for the bed plate end of the floating track

A floating channel and vibration isolation technology, applied in the field of vibration isolation device and plate end vibration isolation device, can solve the problem that the horizontal position and stability requirements of the floating plate cannot be met, and the prefabricated long plate is difficult to adapt to the changing curve elements. , Affecting driving safety and other issues, to achieve the effect of convenient and fast transportation and hoisting, easy product quality assurance, and saving maintenance waiting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

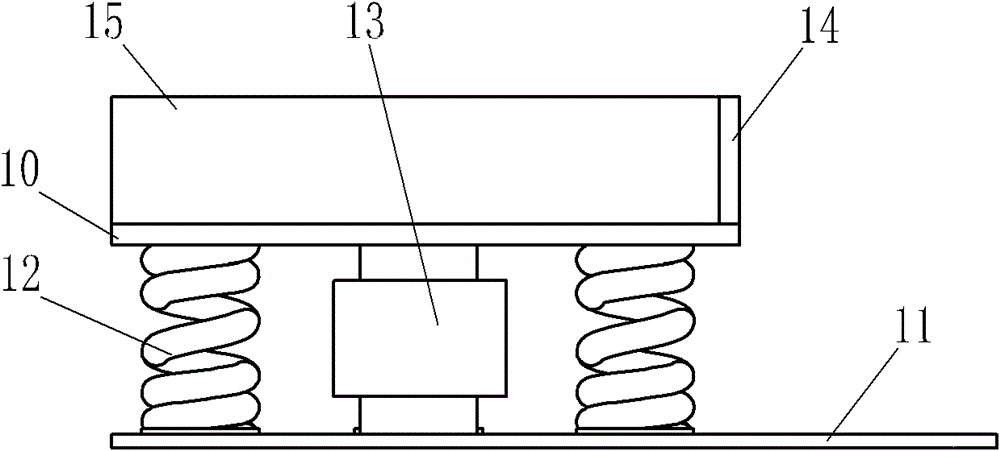

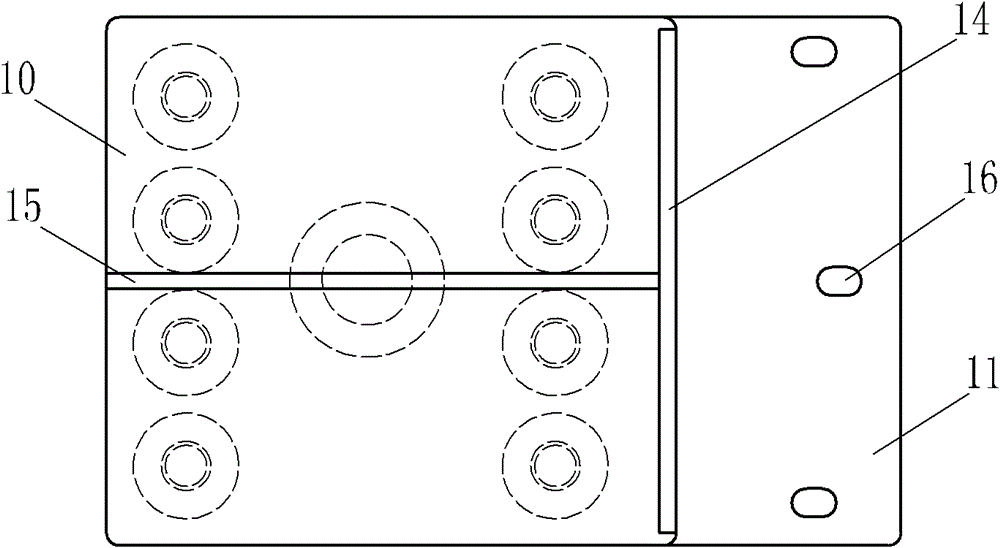

[0075] Such as figure 1 with figure 2 The vibration isolation device at the end of the floating track bed of the present invention includes a top plate 10, a bottom plate 11, an elastic element 12 and a damping element 13. The elastic element 12 and the damping element 13 are arranged between the top plate 10 and the bottom plate 11. In this example, the elastic element 12 is specifically eight helical steel springs, and the damping element 13 is specifically a small-hole throttling damper, and the elastic element 12 and the damping element 13 are arranged symmetrically along the transverse middle section of the vibration isolation device at the end of the floating track bed. In addition, a plate end horizontal limit device is also provided on the top plate 10, and the plate end horizontal limit device is composed of a plate end transverse limit device and a plate end longitudinal limit device. Wherein, the plate end lateral limiting device is a transverse limiting protrusio...

Embodiment 2

[0083] Such as Figure 8 with Figure 9 The difference between the floating bed end vibration isolation device of the present invention and the first embodiment is that the floating road bed end vibration isolation device is provided with two sets of plate end longitudinal limit devices, and each set of plate end longitudinal limit devices consists of longitudinal A limiting plate 33 , an adjusting bolt 35 and a locking nut 34 are formed. The adjusting bolt 35 is set through a supporting plate 36 , and the supporting plate 36 is welded and fixed together with the lateral limiting protrusion 14 and the top plate 10 .

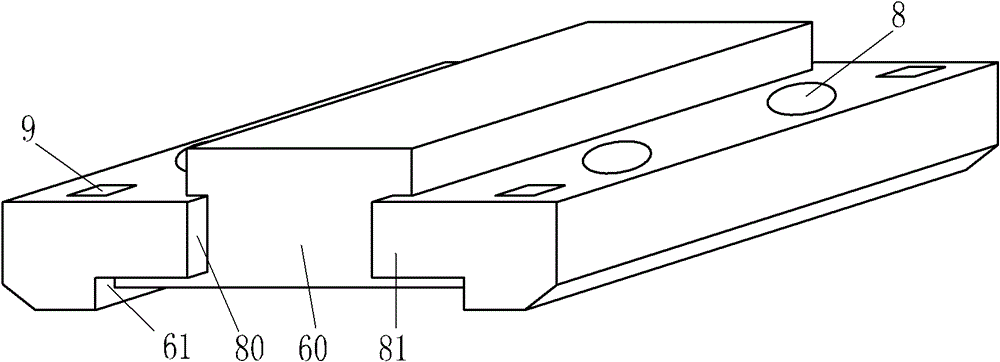

[0084] Such as Figure 11 Prefabricated short panels shown, with image 3 The difference between the prefabricated short slabs shown is that each prefabricated short slab is provided with four placement grooves 27 that cooperate with elastic vibration isolators, and in addition, two mid-mounted shear hinges are symmetrically arranged on the end faces of the pre...

Embodiment 3

[0089] Based on the technical principle described in Embodiment 2, such as Figure 14 with Figure 15 The difference between the floating bed end vibration isolation device of the present invention and the second embodiment is that in this example, the floating road bed end vibration isolation device is provided with two sets of longitudinal limit plates 33, adjusting bolts 35 and In addition to the plate end longitudinal limiting device formed by the locking nut 34, two groups of plate end transverse limiting devices composed of the transverse limiting plate 40, the adjusting bolt 42 and the locking nut 41 are also provided, wherein the plate end lateral limiting The adjusting bolt 42 in the device is set through the support plate 43, and the support plate 43 is welded and fixedly connected with the top plate 10 and the support plate 36 respectively.

[0090] Apply the vibration isolation device at the end of the floating track bed of the present invention described in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com