Sounding rod debugging device for determining datum point of blast-furnace charge level and debugging and positioning method of device

A technology of blast furnace material surface and positioning method, which is applied to inspection devices and other directions, can solve the problems of inconvenient operation, cumbersome debugging, low accuracy, etc., and achieve the effects of accurate detection of material lines, reduced labor intensity, and convenient and simple debugging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

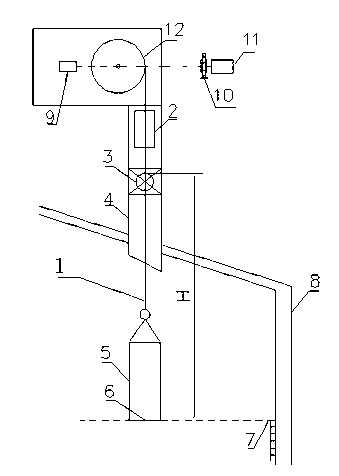

[0021] A probe debugging device for determining the reference point of a blast furnace charge level, comprising a probe pendant 5, an absolute encoder 9, a motor 11, a drum 12, a cable 1, a ball valve 3 and a blast furnace pipe 4, and a ball valve is arranged on the blast furnace pipe. The output of the motor is connected to the drum, one end of the cable is wound on the drum, and the other end of the cable passes through the blast furnace pipe and the ball valve and enters the blast furnace, and is connected with the vertical head of the probe; the motor and the shaft of the drum are provided with an absolute encoder.

[0022] A brake 10 is provided on the motor and drum shaft; a probe inspection hole 2 is provided on the blast furnace pipeline.

[0023] The absolute encoder is a rotary multi-turn absolute encoder.

[0024] In this embodiment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com