Internal and external heat combined coal destructive distillation equipment and coal destructive distillation process thereof

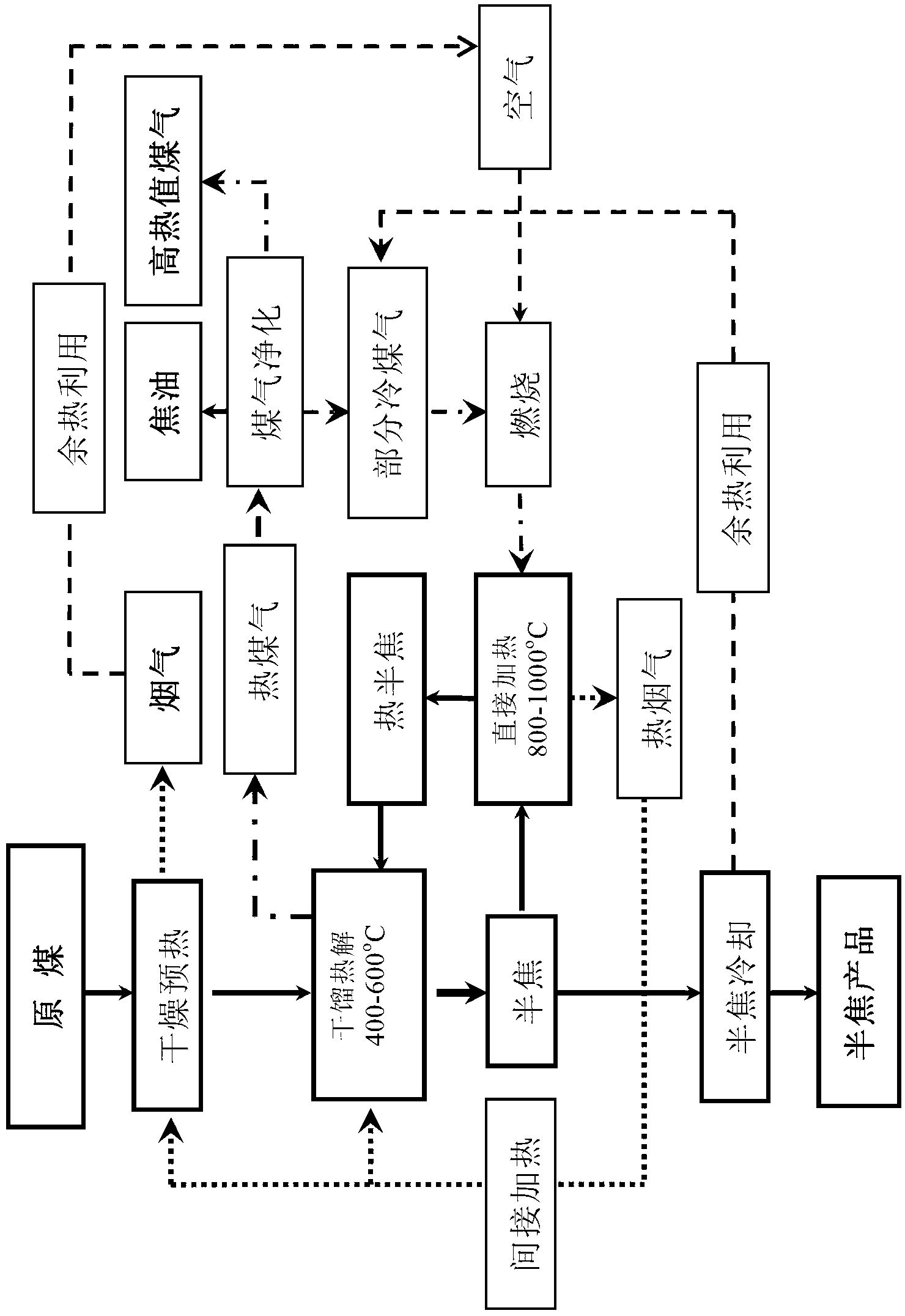

A combined, internal and external heating technology, applied in the field of coal chemical industry, can solve problems such as difficulties in hot semi-coke transportation, achieve the effects of ensuring gas quality, avoiding pollution, and improving the utilization rate of calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The raw coal mentioned in the present invention is crushed coal with a particle size not greater than 30 mm or noodle coal with a particle size not greater than 30 mm.

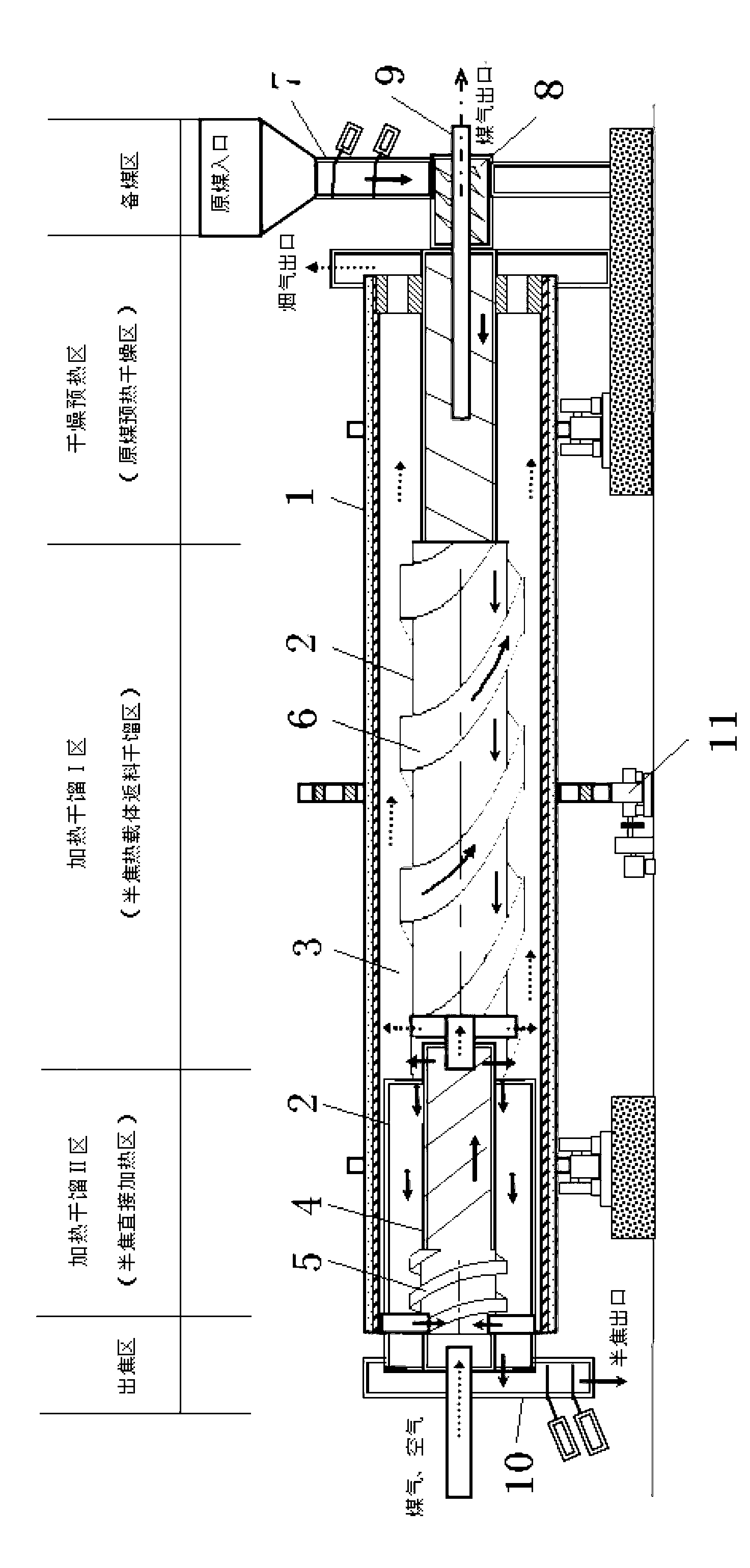

[0039] reference figure 1 The coal dry distillation equipment of the present invention generally includes an outer cylinder 1 and an inner cylinder 2 fixedly installed in the outer cylinder 1 along the axial direction of the outer cylinder 1. The two ends of the inner cylinder 2 are the equipment feed end and the equipment discharge end (by The feeding direction of the equipment is from the feeding end of the equipment to the discharging end of the equipment. A feeding device 7 is installed at the equipment feeding end of the inner cylinder 2 and a discharging device 10 is installed at the equipment discharge end. The feeding device 7 adopts the traditional structure. In addition to the conventional feeding flaps and other components, the key component is the feeding screw 7 connected to the inner cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com