Preparation method and application of KSc2F7:Yb, Er up-conversion fluorescent nanorod

A nanorod, ksc2f7 technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of sensitive synthesis conditions, few reports of nanorods, and unreported synthesis and optical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

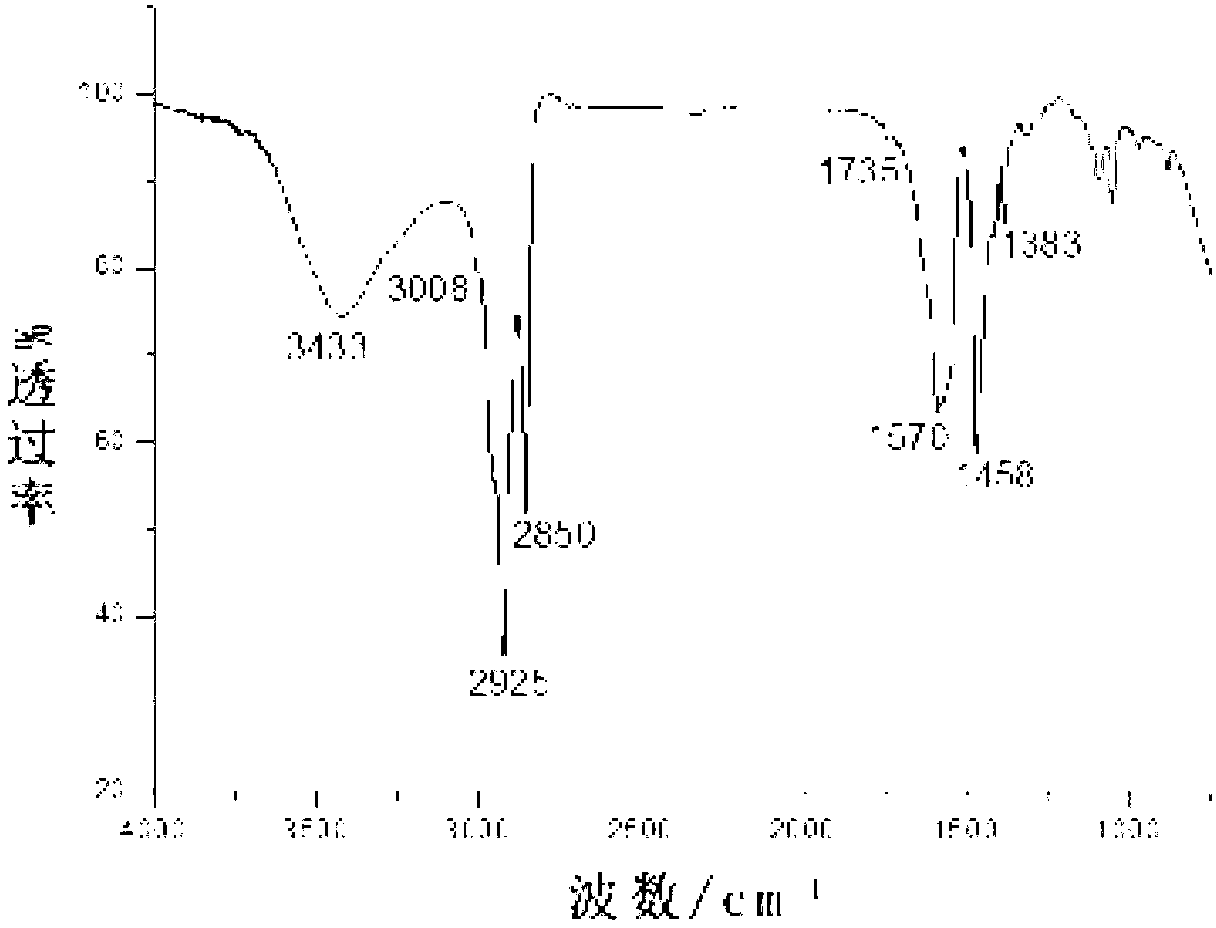

[0020] Example 1. Pure KSc 2 f 7 : Preparation of Yb, Er nanorods

[0021] The preparation method of nanorods is described in the original literature (see: F.Wang, Y.Han, C.S.Lim, Y.Lu, J.Wang, J.Xu, H.Chen, C.Zhang, M.Hong and X.Liu , Nature2010, 463, 1061-1065) on the basis of changing the reaction monomer synthesis preparation. Put 1mmol RECl 3 (0.78mmol ScCl 3 .6H 2 O, 0.2mmol YbCl 3 .6H 2 O, 0.02 mmol ErCl 3 .6H 2 O) join in a round bottom flask that 15ml oleic acid and 17.5ml octadecene are housed, the solution is heated to 160 ℃, stirred reaction 30min, is cooled to room temperature. Contains 1.6mmol NH 4 F and 1.0mmol KOH in 10mL methanol solution were added to the solution and stirred for 30min. The methanol was evaporated, the solution was heated to 290°C under the protection of nitrogen, reacted for 1h, cooled to room temperature, added ethanol to precipitate, washed 3 times with 10mL water and 10mL ethanol, and dried under vacuum to obtain KSc 2 f 7 : ...

Embodiment 2

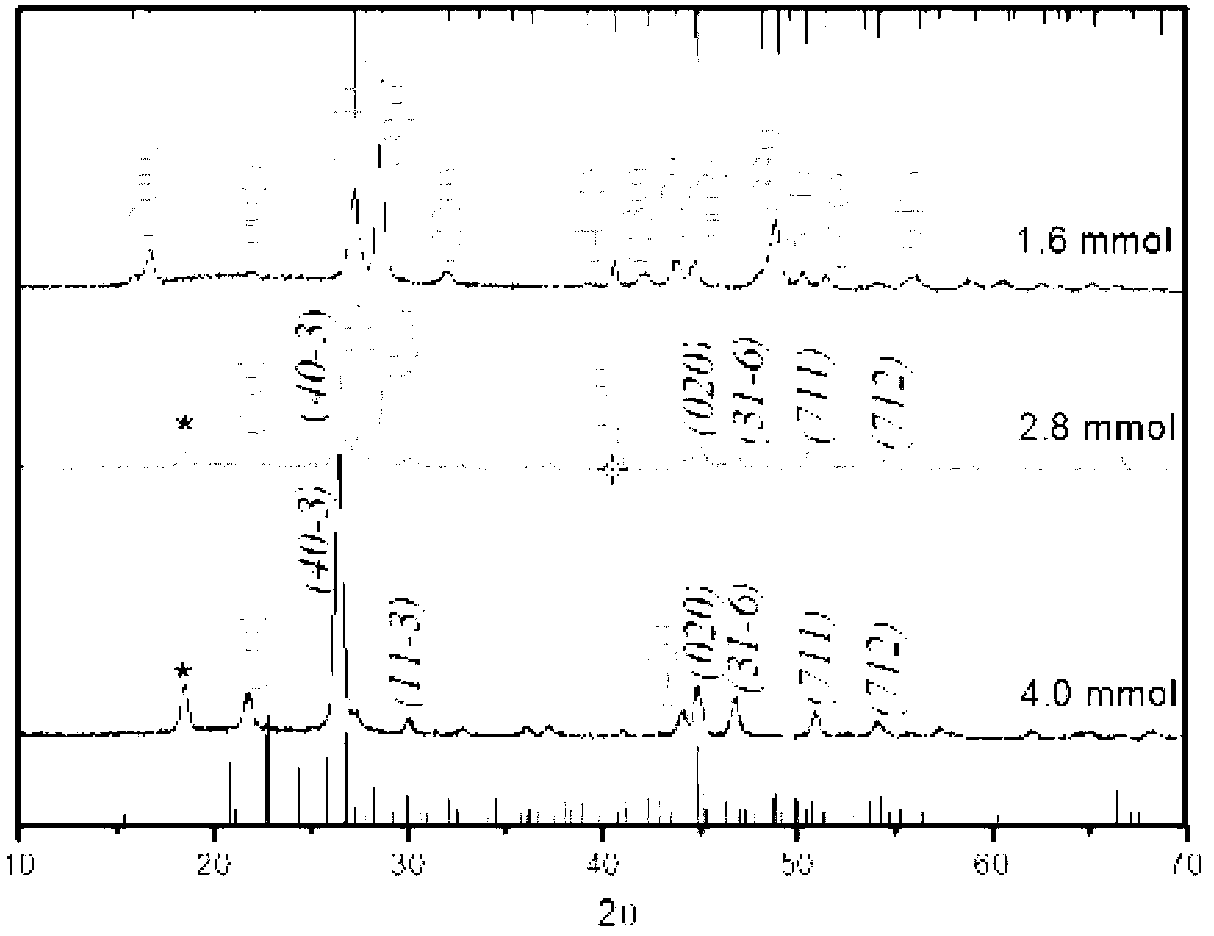

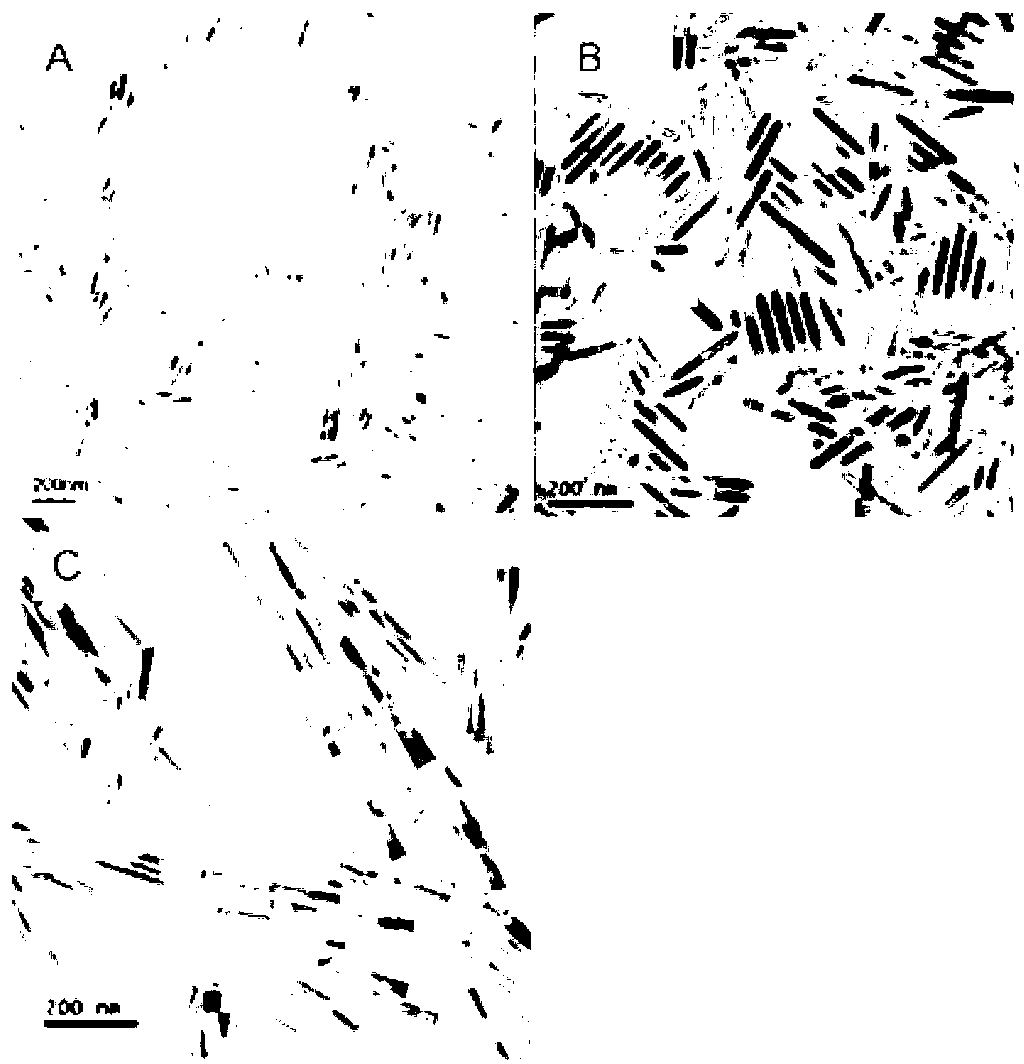

[0022] Example 2. Doping with KScF 4 : Yb, KSc of Er nanoparticles 2 f 7 : Preparation of Yb, Er nanorods

[0023] According to the step of embodiment 1, preparation is doped with KScF 4 : Yb, KSc of Er nanoparticles 2 f 7 : Preparation of Yb, Er nanorods, but NH 4 The amount of the substance of F was 2.8 and 4 mmol, respectively, and the other steps were the same. figure 2 and image 3 The NH 4 XRD pattern and TEM pattern when the amount of F is 4, 2.8 and 1.6 times of the rare earth content, respectively.

Embodiment 3

[0024] Example 3. Pure KSc 2 f 7 : Preparation of Yb, Er nanorods

[0025] Prepare KSc according to the steps of Example 1 2 f 7 : Yb, Er nanorods, but the temperature is changed to 270 °C, and the other steps are the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com