Manufacturing method of ketone-anhydride type polyimide composite retainer tube blank

A polyimide technology and a manufacturing method, which are applied in the field of cages, can solve the problems of insoluble and infusible, poor formability and the like, and achieve the effects of high tensile strength, high high temperature strength retention rate, and improved tribological properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

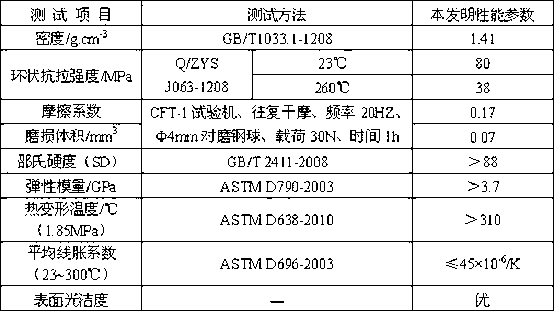

Embodiment 1

[0023] Method of the present invention contains five steps altogether:

[0024] The first step is drying treatment of ketone anhydride type polyimide molding powder and carbon fiber;

[0025] In the second step, proportioning is carried out by weight percentage and a ketone anhydride type polyimide molding powder composite material is prepared;

[0026] The third step is the size and composition of the cage mold;

[0027] The fourth step is the thermocompression molding of ketone anhydride type polyimide molding powder composite material;

[0028] The fifth step is the annealing treatment of the tube blank of the ketone anhydride type polyimide composite cage.

[0029] The above-mentioned second step uses the ketone anhydride type polyimide molding powder as the base material and adds carbon fiber and lubricating modified material polytetrafluoroethylene and prepares the ketone anhydride type polyimide molding powder composite material;

[0030] The above-mentioned third st...

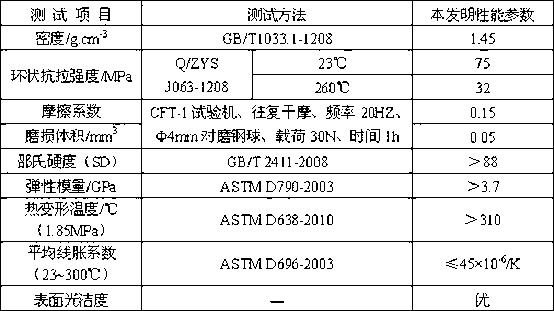

Embodiment 2

[0051] The cage mold includes a jacket, a core, a punch and a base, and the inner diameter of the cage is set to d=28.2mm, the outer diameter is D=35.6mm, and the height is H=6.6mm;

[0052] The first step is ketone anhydride type polyimide molding powder and carbon fiber drying treatment

[0053] Put the ketone anhydride type polyimide molding powder and carbon fiber in a drying oven for drying treatment. The temperature of the drying oven is controlled at 200°C. After drying for 3 hours, take it out and cool it to room temperature, and then pass through a 200-mesh sieve and store it in an independent seal. spare;

[0054] The second step is to proportion according to the weight percentage and prepare the ketone anhydride type polyimide molding powder composite material. The weight percentage ratio of the ketone anhydride type polyimide composite cage tube blank material is: After mixing 75% imide molding powder, 13% carbon fiber, and 12% polytetrafluoroethylene, put the abo...

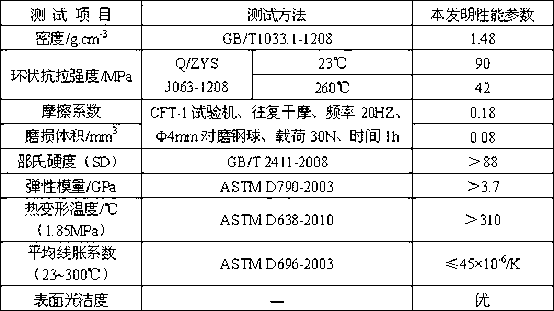

Embodiment 3

[0066] The cage mold includes a jacket, a core, a punch and a base, and the inner diameter of the cage is set to d=28.2mm, the outer diameter is D=35.6mm, and the height is H=6.6mm;

[0067] The first step is ketone anhydride type polyimide molding powder and carbon fiber drying treatment

[0068] Put the ketone anhydride type polyimide molding powder and carbon fiber in a drying oven for drying treatment. The temperature of the drying oven is controlled at 200°C. After drying for 3 hours, take it out and cool it to room temperature, and then pass through a 200-mesh sieve and store it in an independent seal. spare;

[0069] The second step is to proportion according to the weight percentage and prepare the ketone anhydride type polyimide molding powder composite material. The weight percentage ratio of the ketone anhydride type polyimide composite cage tube blank material is: Imide molding powder 85%, carbon fiber 8%, polytetrafluoroethylene 7%; after proportioning, put the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com