A Hydraulically Driven Fully Vectored Waterjet Propeller Nozzle

A water jet propulsion, full vector technology, applied in ship propulsion, propulsion parts, ship parts, etc., can solve the problems of large energy and power loss, unfavorable high-speed adjustment, limited adjustment ability, etc., to achieve low power loss and compact structure. , the effect of improving maneuverability and maneuverability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings and embodiments.

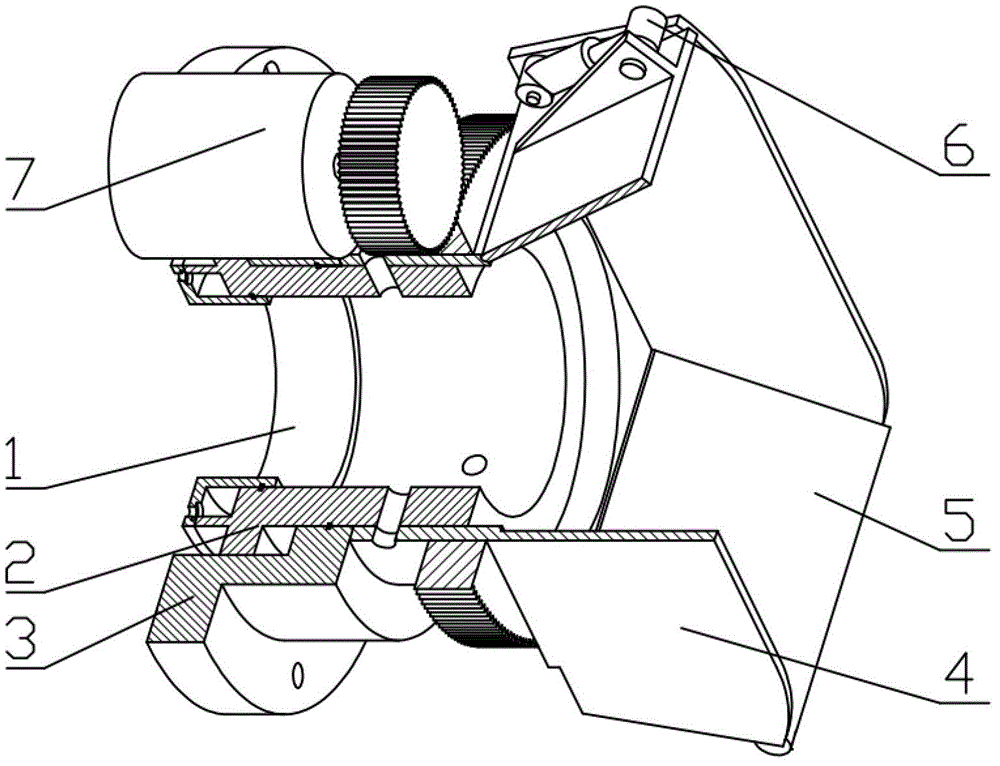

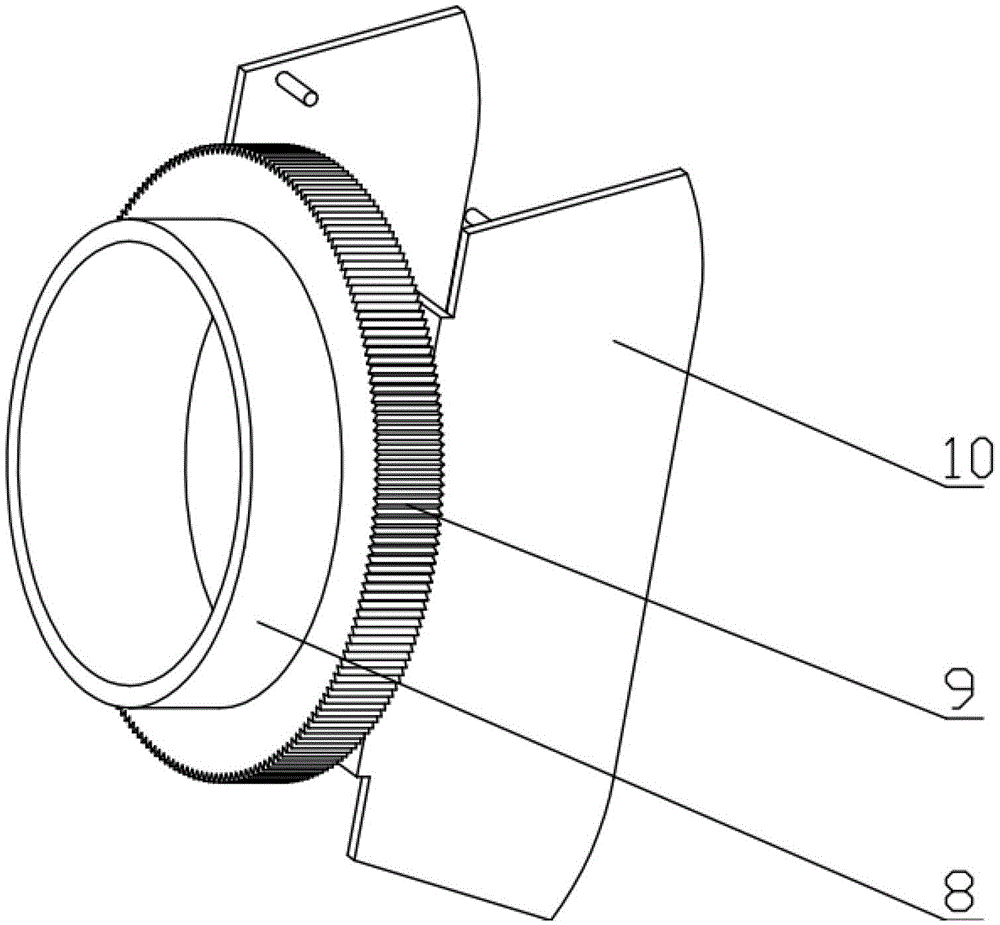

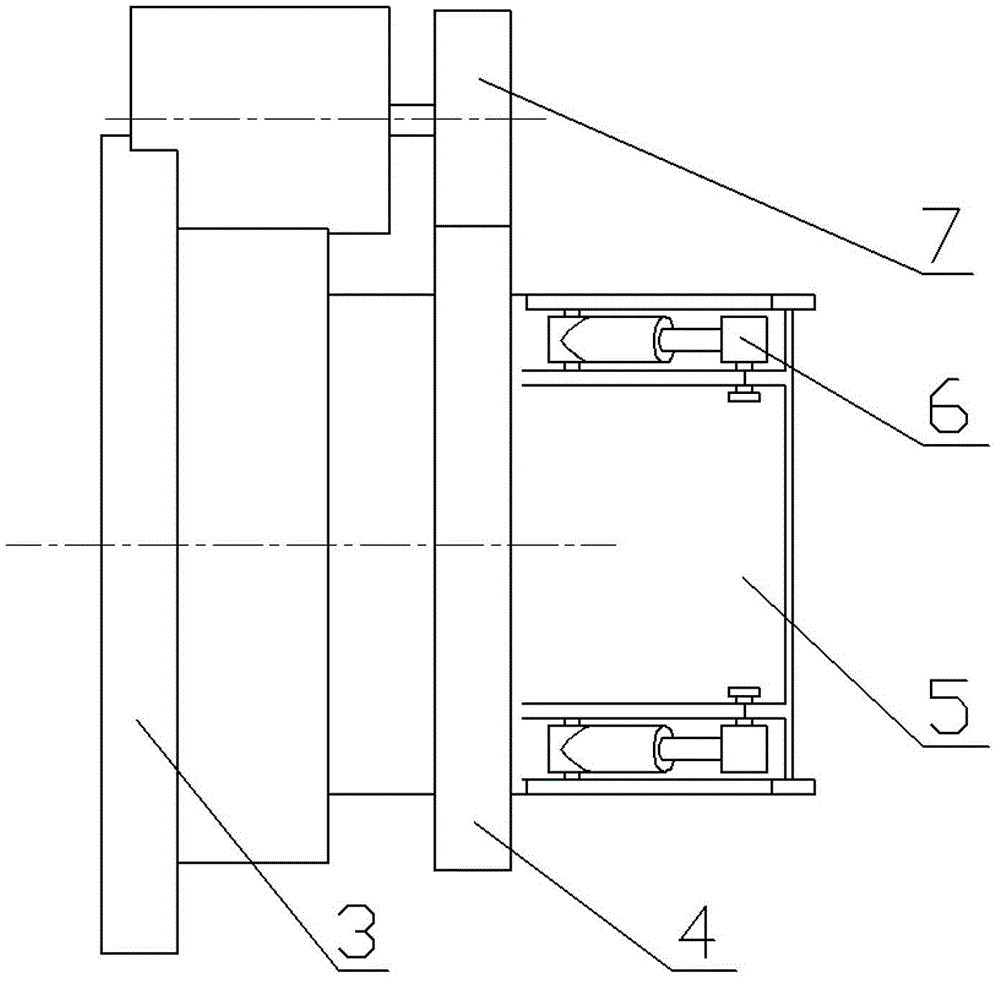

[0024] As attached figure 1 with 3 As shown, the present invention provides a hydraulically driven full vector waterjet nozzle, including a rotating blade assembly 4, a swinging blade 5, a sealing base 1, a rotating support sleeve 2, a compression cover 3, a hydraulic motor 7, and a hydraulic Cylinder 6; the peripheral equipment is a controllable hydraulic pump system, which includes a hydraulic pump, a control system, a hydraulic valve and a hydraulic oil circuit. The control system in the controllable hydraulic pump system controls the hydraulic pumps according to working conditions, respectively, hydraulic motor 7 and hydraulic cylinder 6 Provide the required power separately; as attached figure 2 As shown, the rotating blade assembly 4 is composed of a transmission sleeve 8, a transmission ring gear 9 and a fixed blade 10; the sealing base 1 and the compression cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com