Servo direct-driven power head for press machine

A direct-drive press technology, applied in the field of presses, can solve problems such as low power factor and complex structure, and achieve the effects of improved reliability, reduced moment of inertia, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

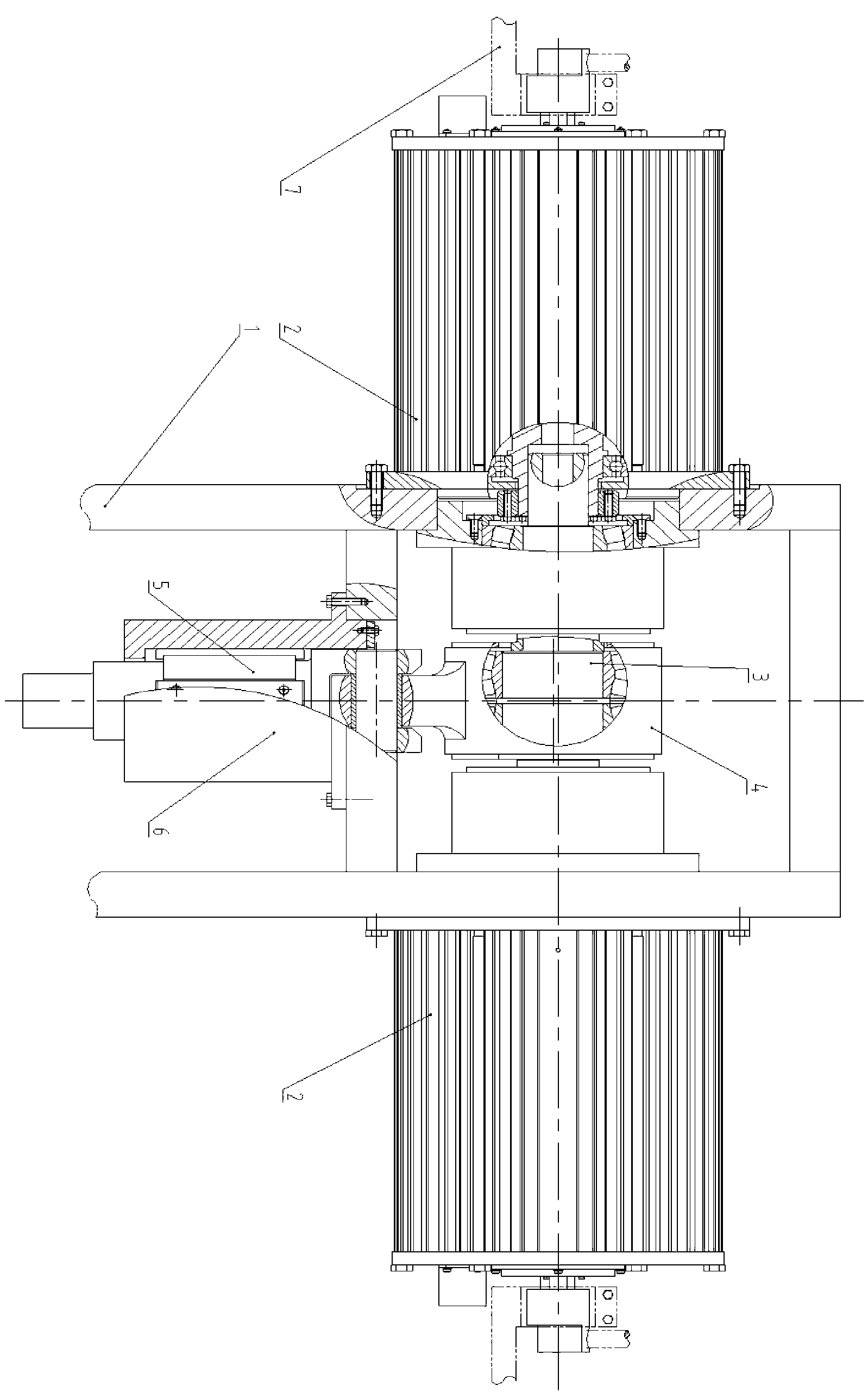

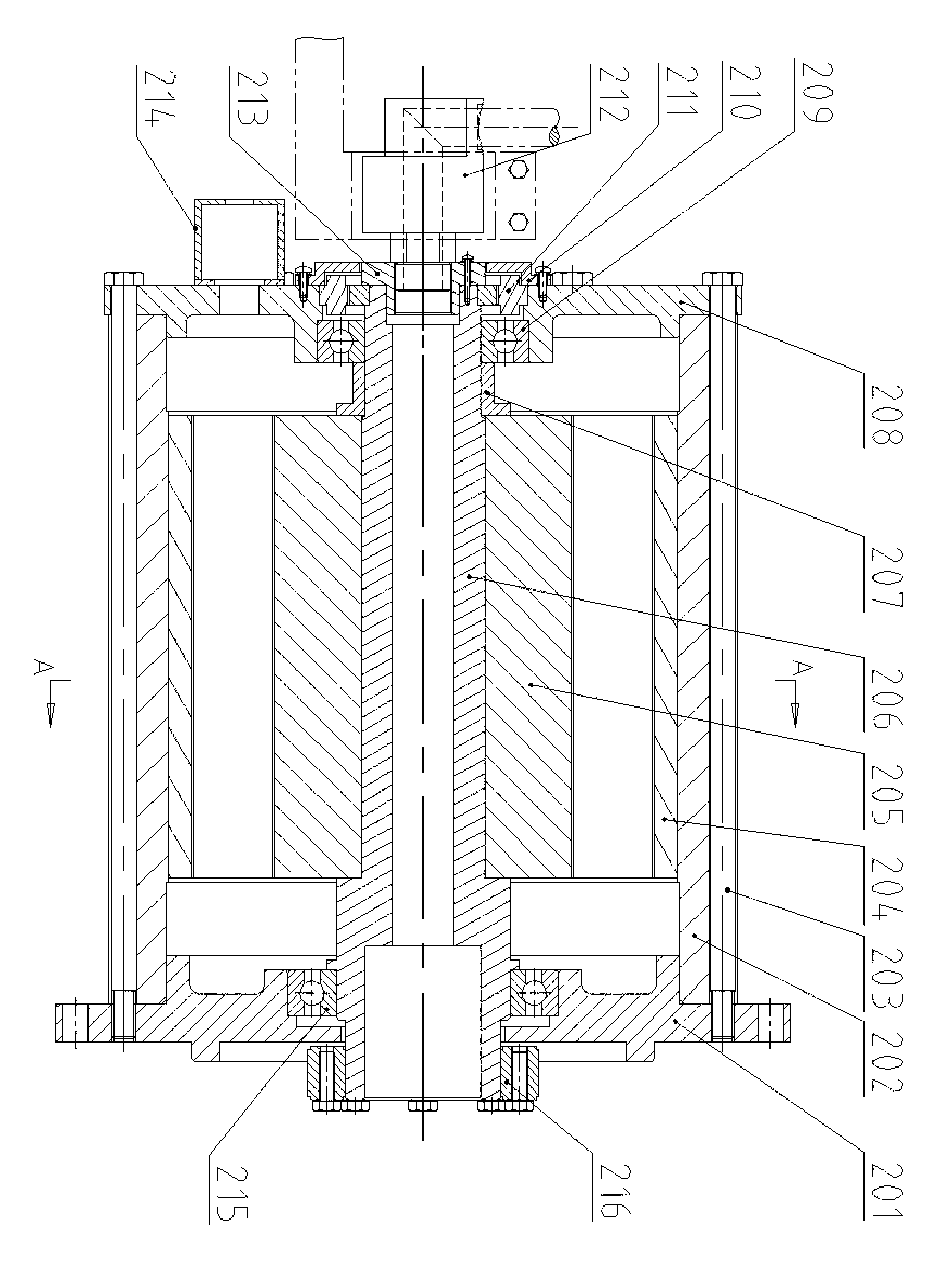

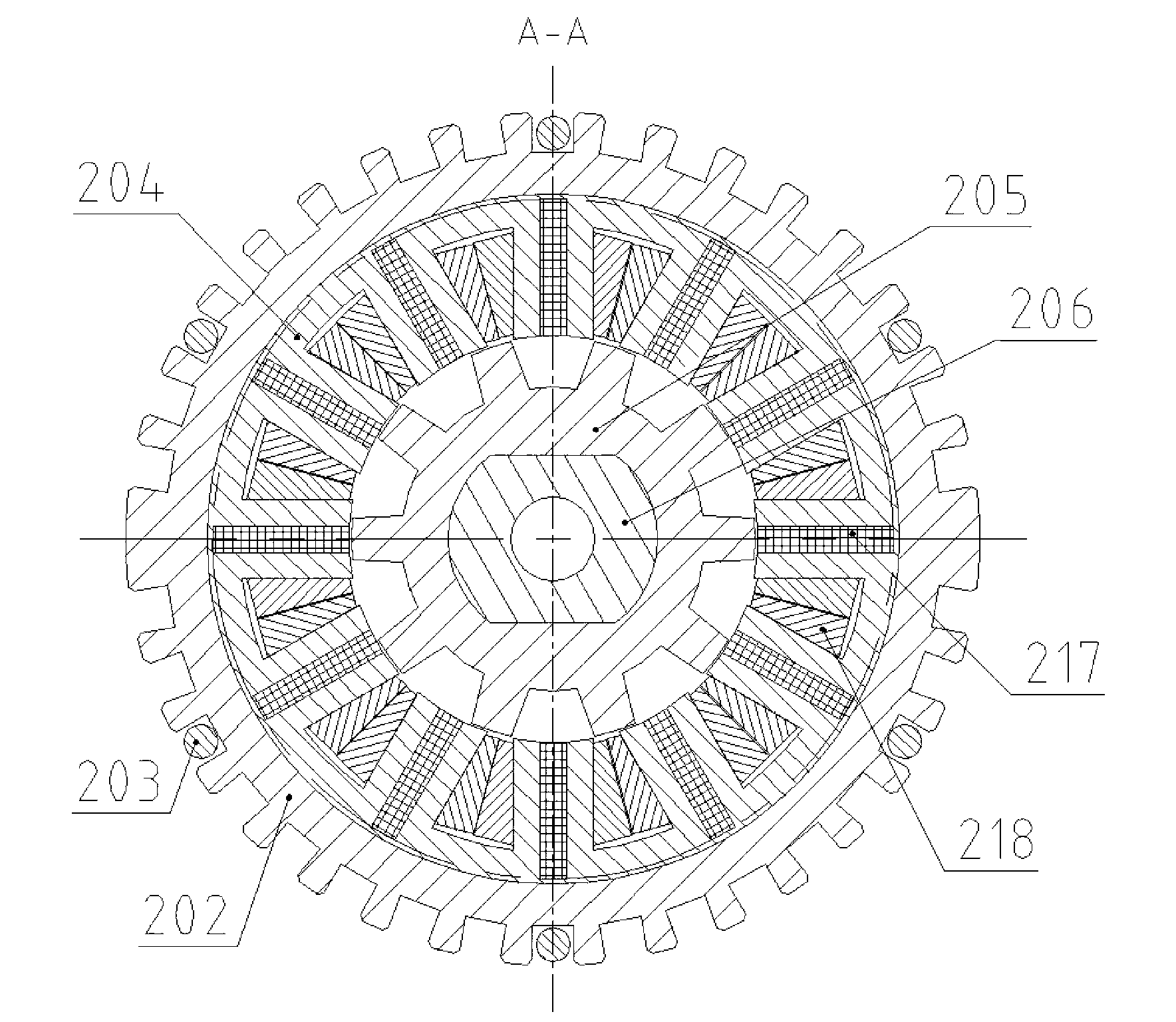

[0015] see figure 1 , a servo direct drive power head for a press, comprising a frame 1, two side walls of the frame 1 are provided with through holes, and a pair of switching flux permanent magnet motors 2 cooperate with the through holes of the frame 1 The bolts are symmetrically installed on both sides of the frame 1, so that the whole system is symmetrical. The hollow eccentric shaft mechanism 3 is installed in the frame 1, and the shaft ends on both sides are inserted into the switch flux permanent magnet motor 2 and connected by pressing force, so that the torque generated by the motor is transmitted to the link mechanism 4 and the slider mechanism 5 on. The link mechanism 4 is installed on the eccentric shaft section in the middle of the hollow eccentric shaft mechanism 3, the slider mechanism 5 is located below the link mechanism 4, the two are conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com