Chelate fiber ABTF and synthetic method thereof

A technology of chelating fibers and synthesis methods, which is applied in the direction of fiber types, fiber treatment, chemical instruments and methods, etc., can solve the problems of direct measurement of trace heavy metals and other problems, and achieve the effects of excellent regeneration performance, environmental protection, and wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

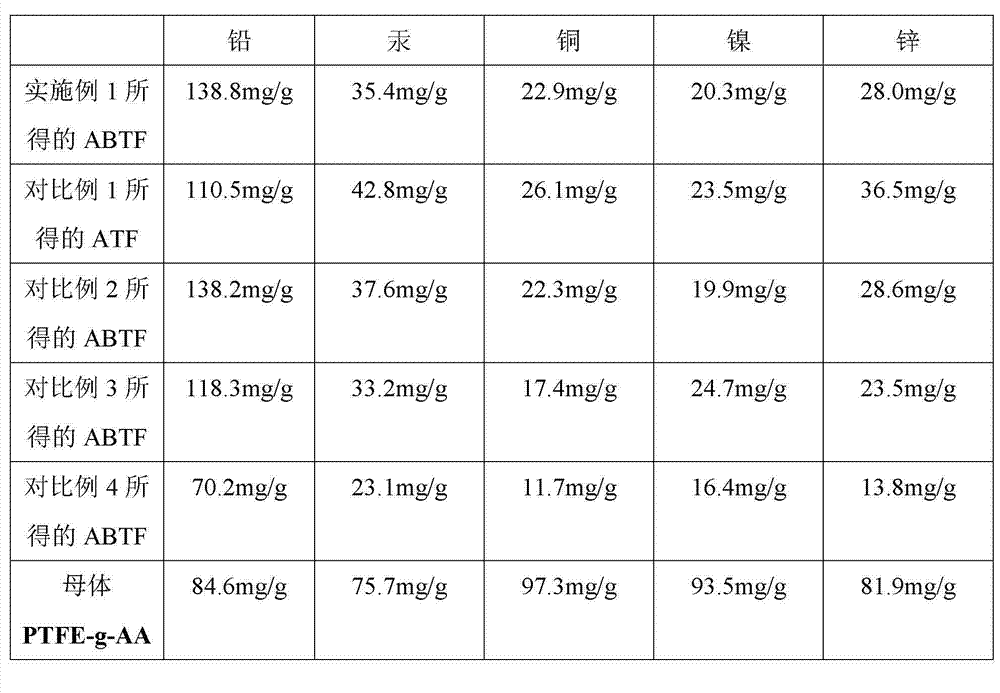

Embodiment 1

[0032] Embodiment 1, a kind of method of synthetic chelating fiber ABTF, carry out following steps successively:

[0033] 1) Put about 20.0 mg of the matrix --- acrylic modified polytetrafluoroethylene fiber (PTFE-g-AA) in a 100 mL three-necked bottle, add 25 mL of toluene and soak for 8 hours;

[0034] Remarks: The content of PTFE-g-AA functional group (ie -COOH) in acrylic modified polytetrafluoroethylene fiber (PTFE-g-AA) is 3.07mmol / g.

[0035] 2) Add 0.184mmol of the ligand—2-aminobenzothiazole (that is, the molar ratio of PTFE-g-AA to the ligand is 1:3) into the three-neck flask, and stir at 70°C for 14 hours , the stirrer speed is 250rpm / min.

[0036] 3) Filter the product obtained in step 2), and wash the obtained filter cake with toluene, ether, and ethanol three times in sequence, and each time: the dosage of DMF, ether, and ethanol is 100ml;

[0037] Put the washed filter cake into a vacuum drying oven at a drying temperature of 40-60°C and dry to constant weight ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com