Preparation method of microcapsule for self-repair material with phenolic resin as wall material

A self-healing material, phenolic resin technology, applied in the directions of microcapsule preparation, microsphere preparation, etc., can solve the difficulties of microcapsules and other problems, and achieve the effect of large size, regular shape and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention also provides a method for preparing microcapsules using phenolic resin as a wall material for self-healing materials, including the following steps:

[0021] S01: Preparation of first-stage thermosetting resin: adjust the pH value of the mixed aqueous solution of phenol and aldehyde to 8-10, heat up to 60-65°C, stir, and then heat up to 70-90°C to react to obtain a reaction solution, wherein the phenol The molar ratio of phenol and aldehyde in the aqueous solution mixed with aldehyde is 1:1~3;

[0022] S02: Preparation of core material emulsion: take 40-120% of the total molar mass of phenol and aldehyde in the phenol and aldehyde aqueous solution, mix dicyclopentadiene, polyacrylic acid and water, heat up to 50-80°C, and stir to obtain Core material emulsion, wherein the mass ratio of dicyclopentadiene, polyacrylic acid and water is 1: (0.5-2): (3-14);

[0023] S03: Mix the core material emulsion with the reaction liquid at 60-...

Embodiment 1

[0033] Weigh 5g of phenol (P) and 6.5g of formaldehyde (F) respectively, place them in a 500mL three-neck flask equipped with a condenser tube reflux device, add 5wt% NaOH aqueous solution to adjust the pH value to 9, first stir at 65°C for 10 minutes, Then the temperature was raised to 70° C. and kept for reaction for 2 hours to obtain a reddish-brown first-stage Resole solution.

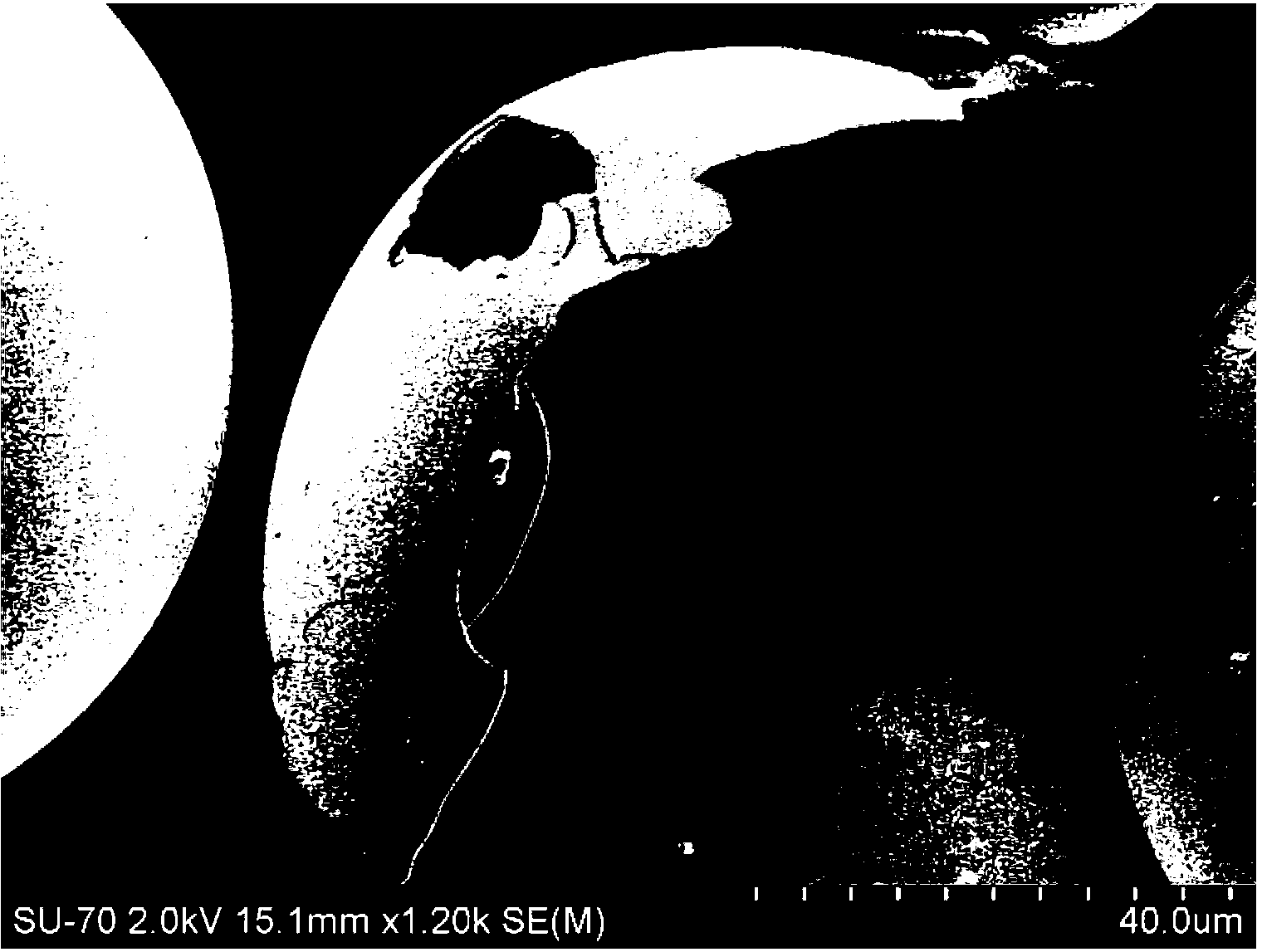

[0034]In another 500mL three-necked flask equipped with a stirrer and a thermometer, add 7g of dicyclopentadiene (DCPD) as the core material, 7g of polyacrylic acid (pH=6-7) as the emulsifier and 50g of distilled water as the continuous phase, Heat to 70°C and stir for 20 minutes at a rotation rate of 1000 rpm to obtain DCPD white emulsion. Adjust the temperature of the DCPD emulsion to 65°C, reduce the stirring rate to 500 rpm, and add the first-stage Resole solution to the DCPD emulsion at a rate of one drop every 4 seconds. After mixing evenly, slowly add 2% hydrochloric acid solution. Adjust t...

Embodiment 2

[0037] Weigh 5g of phenol (P) and 7.5g of formaldehyde (F) respectively, place them in a 500mL three-neck flask equipped with a condenser tube reflux device, add 5wt% NaOH aqueous solution to adjust the pH value to 10, first stir at 65°C for 10 minutes, Then the temperature was raised to 80° C. and the reaction was kept for 1.5 hours to obtain a reddish-brown Stage A Resole solution.

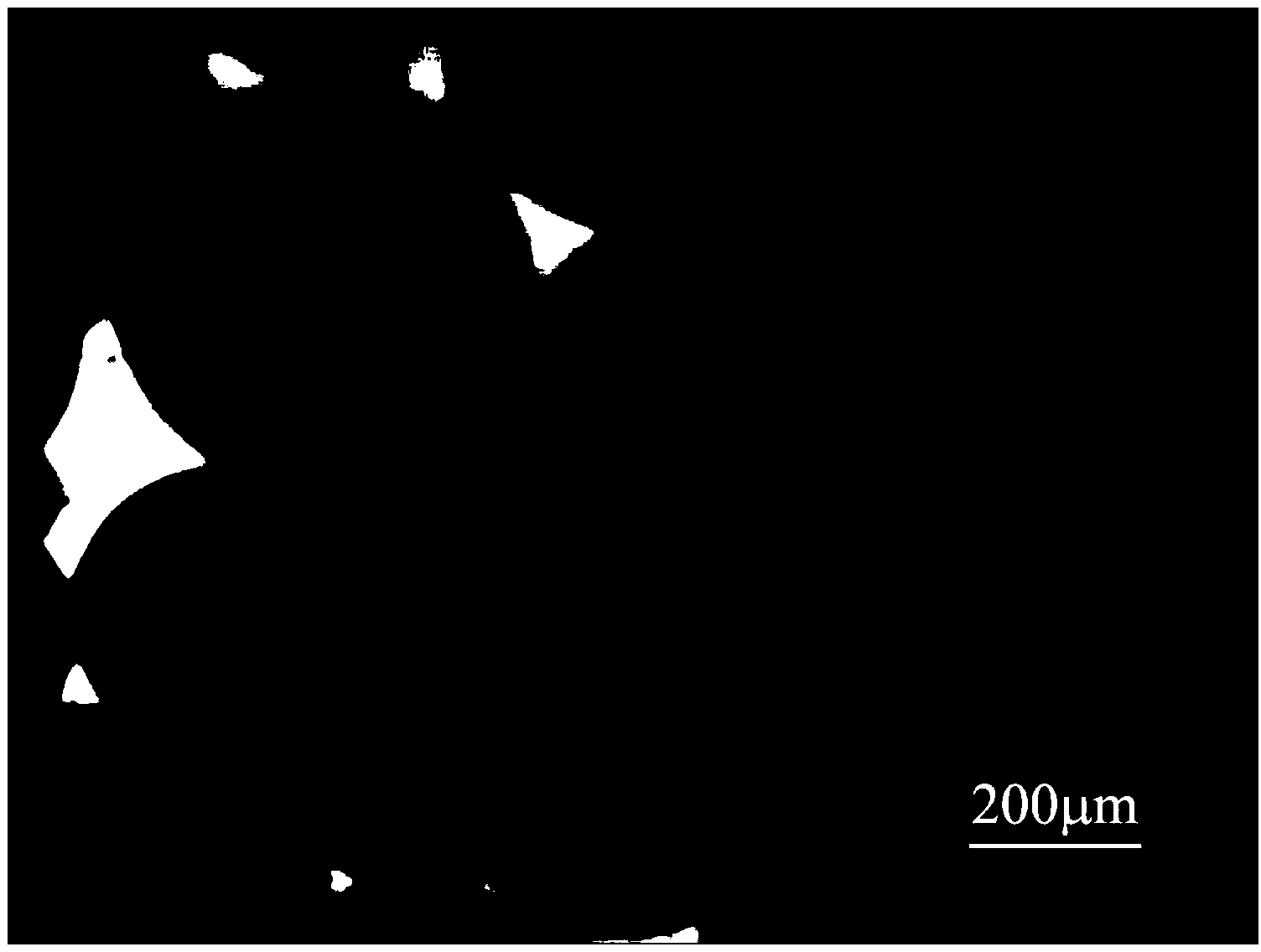

[0038] In another 500mL three-necked flask equipped with a stirrer and a thermometer, add 14g of dicyclopentadiene (DCPD) as the core material, 20g of polyacrylic acid (pH=6-7) as the emulsifier and 100g of distilled water as the continuous phase, Heat to 70°C and stir for 20 minutes at a rotation rate of 1000 rpm to obtain DCPD white emulsion. Adjust the temperature of the DCPD emulsion to 65°C, reduce the stirring rate to 300 rpm, add all the first-stage Resole solution directly into the DCPD emulsion, mix well, slowly add 2% hydrochloric acid solution dropwise, adjust the pH value to 2, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com