A high throughput tray tower

A plate tower, high-throughput technology, applied in the field of plate fractionation or rectification tower, plate tower internals structure, can solve the problem of affecting the operation flexibility and separation efficiency, reducing the liquid flow intensity of the tray plate, and reducing the mass transfer efficiency. , to achieve the effects of improving mass transfer efficiency and processing capacity, expanding the range of bubbling area, reducing liquid surface gradient and liquid layer thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

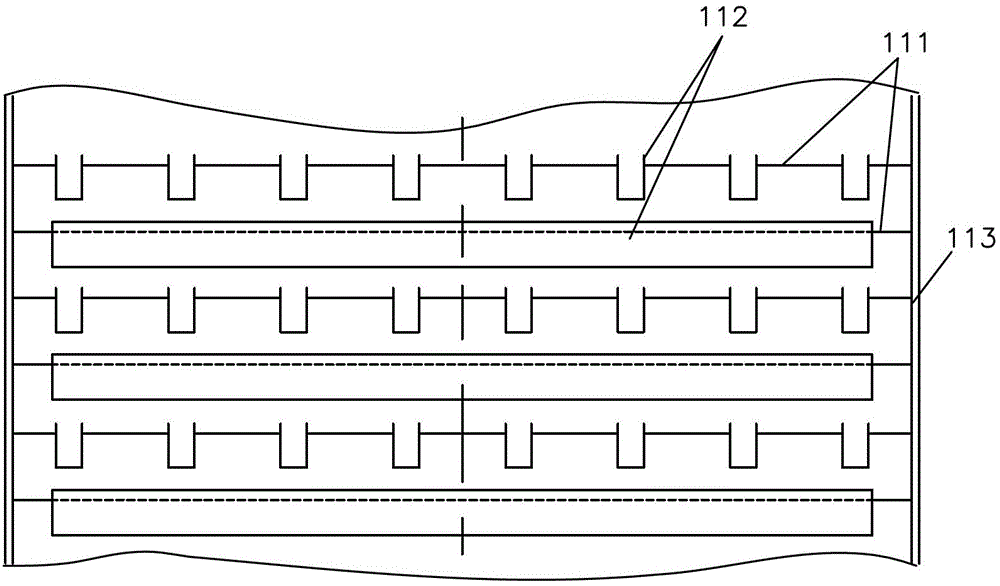

[0046] The plate tower internals are located inside the tower shell 5 and are arranged in a stacked structure. Each layer includes a tray plate 1, a downcomer 7, and a liquid receiving plate 4. That is, one end of each tray plate is connected to the liquid receiving plate, and the other end is connected to the liquid receiving plate. To the downcomer, the tray plate of the lower layer corresponds to the tray plate of the upper layer, and the liquid receiving plate of the lower layer corresponds to the downcomer setting of the upper layer, arranged layer by layer. This structure is the prior art.

[0047] Such as image 3 , 4 , 5, a high flux tray tower, the tray plate 1 is inclined downward along the liquid flow direction, that is, the end connected to the liquid receiving tray is the upper end of the tray plate 1, and its The end communicating with the downcomer is the lower end of the tray plate 1 . The angle a between the tray plate and the horizontal line is 3°-45°. The...

Embodiment 2

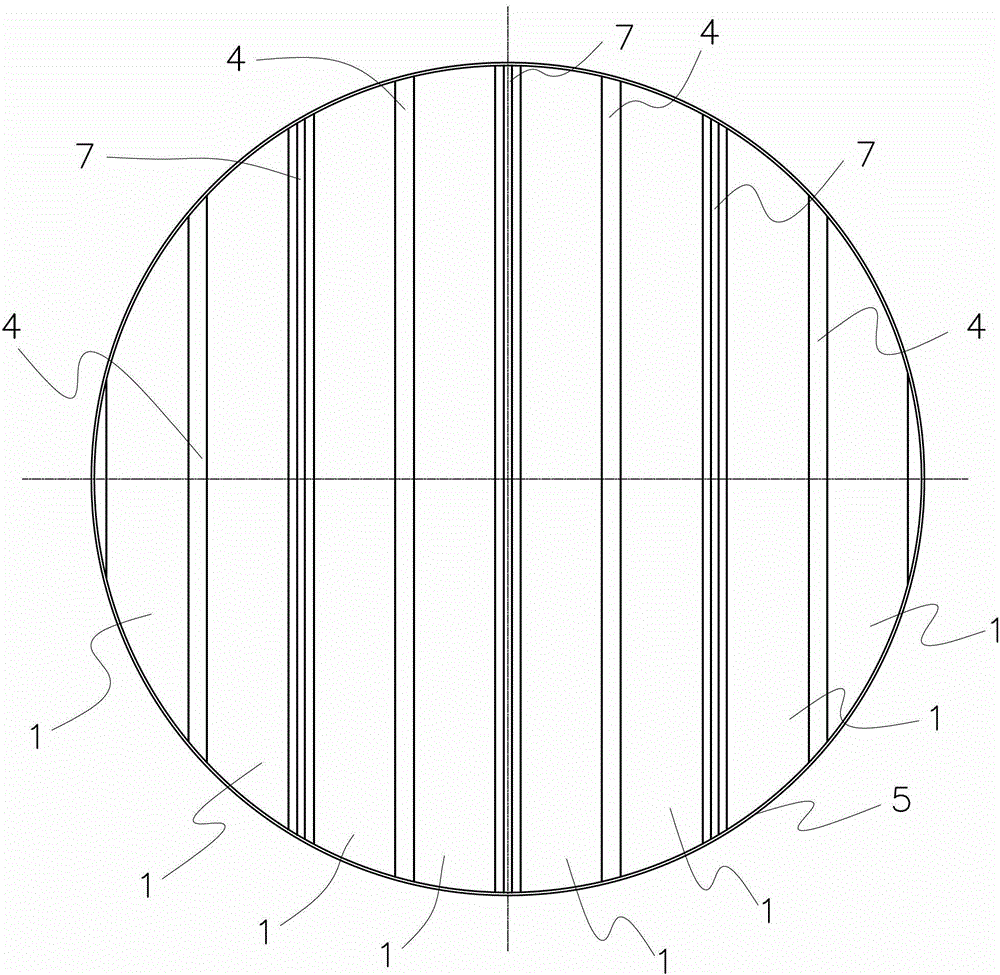

[0055] Such as Figure 6 As shown, a high-throughput tray column, the tray column internals are located inside the column shell, including tray plates, downcomers, and liquid receiving trays. A total of 117 trays are installed in the plate fractionation tower. According to the vapor-liquid load and the nature of the system in the fractionation tower, the tower diameter Ф6600mm, 8 liquid flow high-flux plate tower structure technology is adopted through hydraulic calculation. The tray plate 1 is inclined downward along the liquid flow direction, that is, the upper end of the tray plate 1 is connected to the liquid receiving tray, and the lower end of the tray plate 1 is connected to the downcomer. . In the middle part of the tray tower, the upper ends of the two opposite tray plates 1 are connected by the liquid receiving tray 4, and the lower ends of the two opposite tray plates 1 form the inlet of the downcomer 7; The upper end of a tray plate 1 is connected to the tower sh...

Embodiment 3

[0060] Such as Figure 7 , a high-throughput tray tower, the tray tower internals are located inside the tower shell 5, including a tray plate, a downcomer, and a liquid receiving tray, and the tray plate 1 is inclined downward along the liquid flow direction, that is, The upper end of the tray plate 1 is connected to the liquid receiving tray, and the lower end of the tray plate 1 is connected to the downcomer. The included angle between the tray plate 1 and the horizontal is 45°. The main function of the inclined tray plate is to improve the liquid flow state on the tray plate, reduce the thickness of the liquid layer, increase the length of the liquid flow and the area of the bubbling area. In the middle of the tray tower, the lower ends of two opposite tray plates form the inlet of the downcomer 7, and the width of the inlet is 100 mm. The tray plate is not provided with an outlet weir, because setting the outlet weir will affect the beneficial effect of the inclined t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com