Surface heating type atomizer and electronic cigarette provided with same

An atomizer and heating technology, used in tobacco, smoker's products, applications, etc., can solve the problems of easy burnout of tungsten alloy heating wire, short service life, less atomized e-liquid, etc., and it is not easy to generate accumulation. The effect of carbon, long service life and strong atomization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

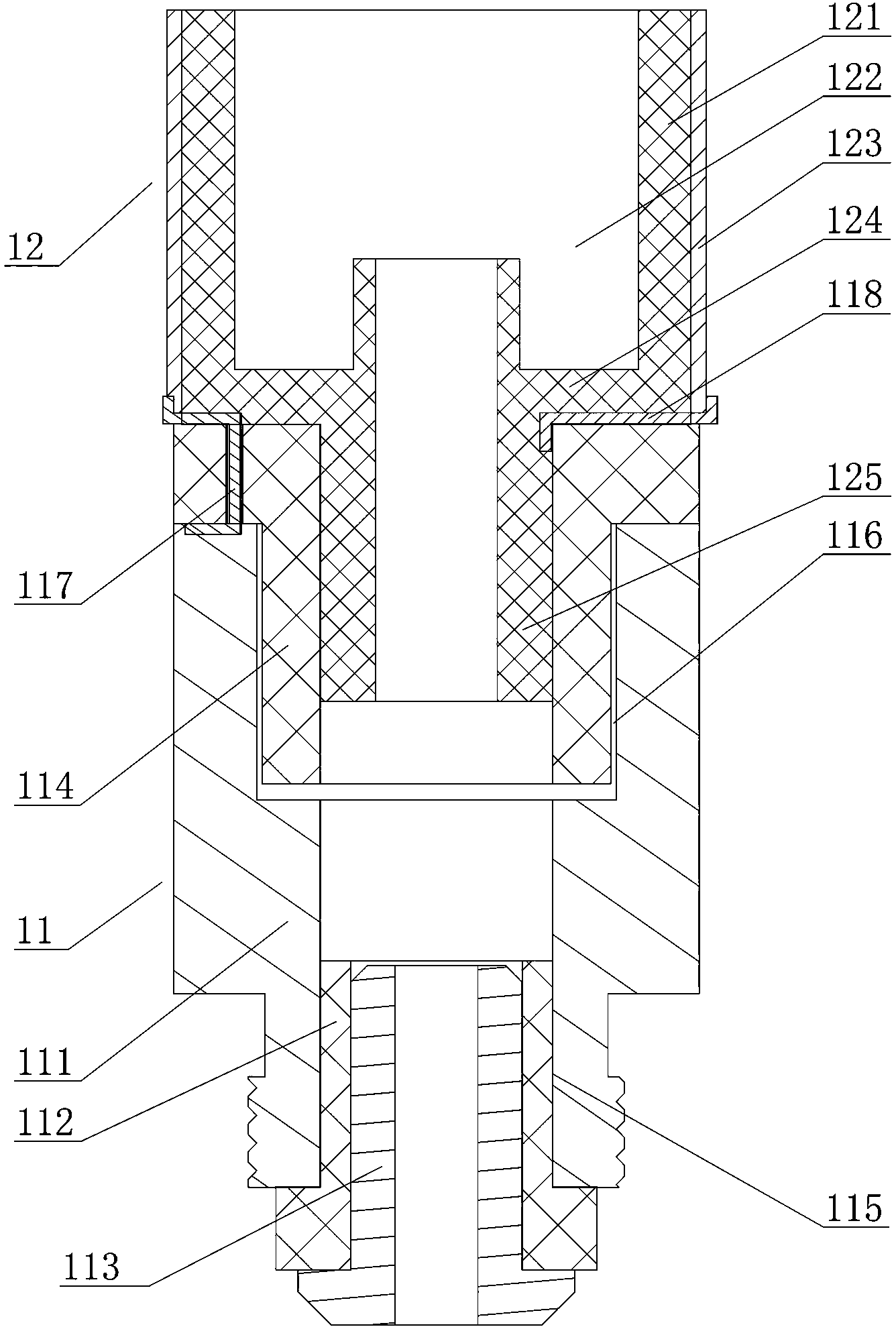

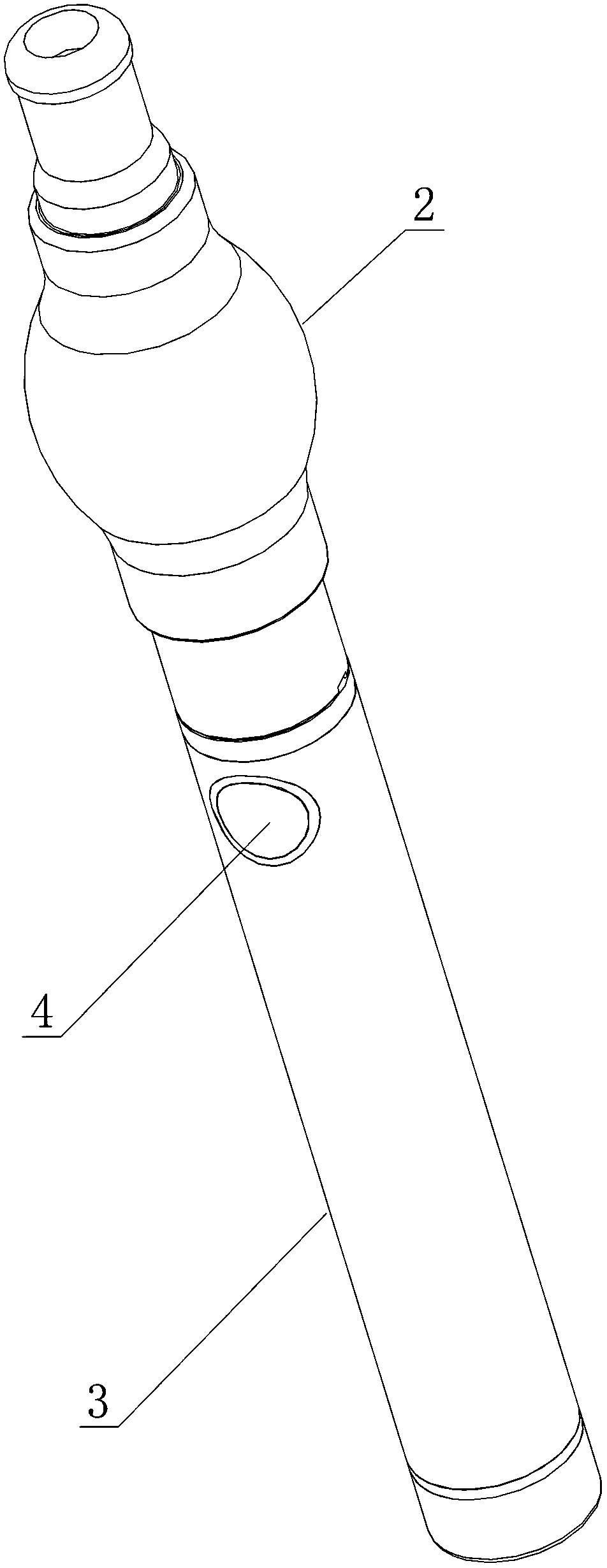

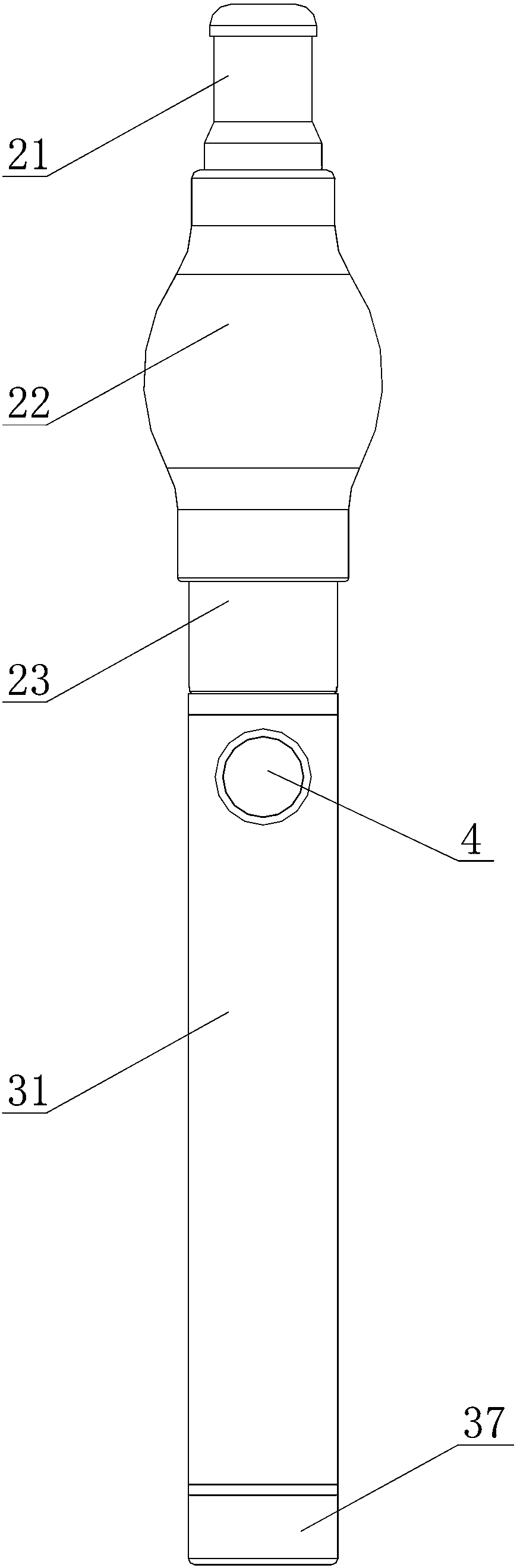

[0026] Such as figure 1As shown, the surface heating atomizer of this embodiment includes a base 11 and a heating element 12 connected to each other. The heating element 12 includes a ceramic seat 121, and the interior of the ceramic seat 121 is provided with a container for placing solid e-liquid or e-liquid. The outside of the groove 122 and the ceramic seat 121 is wrapped with a nano-titanium metal heating material film 123 . In this embodiment, the nano-titanium metal heating material film 123 is used instead of the traditional tungsten alloy heating wire to heat solid smoke oil or smoke paste. When the nano-titanium metal heating material film 123 is energized, the ceramic seat 121 can be heated to 400-600 °C. Celsius, so that the solid e-liquid or e-liquid placed in the accommodating tank 122 can be atomized. Compared with the traditional atomizer using tungsten alloy heating wire, it has the following technical effects: 1) the traditional tungsten alloy The heating wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com