Smoke forming agent for hot smoke type pesticide application technology

A hot smoke and smoke-forming technology, applied in the application, biocide, animal repellent, etc., can solve the problems of increasing work efficiency, ineffectiveness, poor diffusivity, etc., achieving large smoke volume, rapid diffusion, and distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

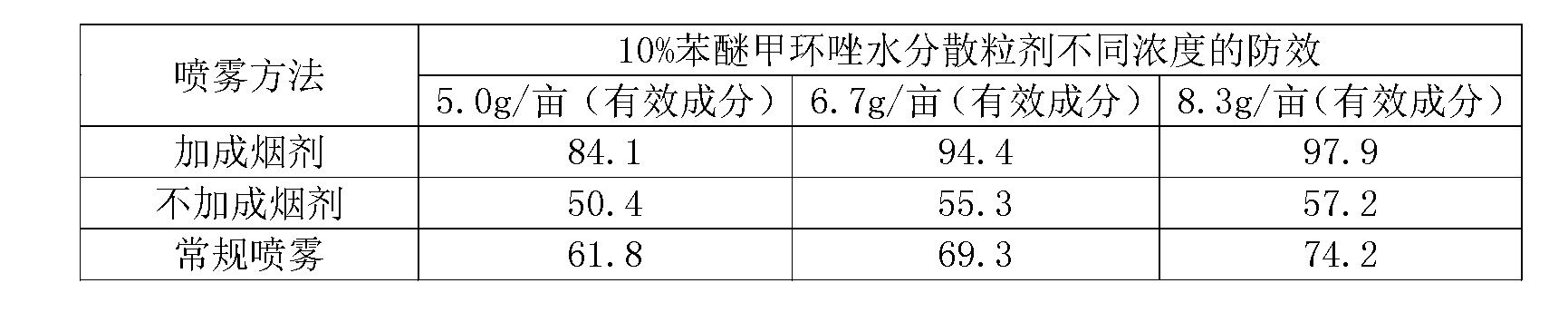

Image

Examples

Embodiment 1

[0016] Take 1.2g of the condensate of alkylphenol and ethylene oxide, 0.3g of calcium dodecylbenzenesulfonate, 0.2g of sorbitol oleate and de-emulsify 5.5g of white oil, and fully stir. After stirring evenly, add 1.5g of ethylene glycol, 1g of isopropanol, and 3g of water, cut it under the high-speed emulsifier for 1min, and then let it stand for 30min. Then add 0.2 g of sodium lauryl sulfate and 0.2 g of xanthan gum. Finally, the above solution was mechanically stirred under a mixer at a certain speed for 20 min.

Embodiment 2

[0018] Take 0.8g of alkylphenol polyoxyethylene polyoxypropylene ether, 0.2g of styrylphenol polyoxyethylene ether, 0.3g of sorbitan oleate, 0.2g of silicone de-emulsified, 2g of diesel oil, and 4g of white oil, and fully stir. After stirring evenly, add 2g of glycerol, 1g of isopropanol, and 3g of water, cut it under the high-speed mixing emulsifier for 1min, and then let it stand for 30min. Then add 0.2 g of pulling powder and 0.2 g of xanthan gum. Finally, the above solution was mechanically stirred under a mixer at a certain speed for 20 min.

Embodiment 3

[0020] Take 0.3g of alkylphenol polyoxyethylene polyoxypropylene ether, 1g of calcium dodecylbenzenesulfonate, 0.3g of sorbitan oleate and de-emulsify 5g of white oil, and fully stir. After stirring evenly, add 1.5g of ethylene glycol, 1g of isopropanol, and 3g of water, cut it under the high-speed emulsifier for 1min, and then let it stand for 30min. Then add 0.15 g of sodium dodecylbenzenesulfonate and 0.15 g of xanthan gum. Finally, the above solution was mechanically stirred under a mixer at a certain speed for 20 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com