Method and damping element for reducing the natural vibration of a component

A technology of damping elements and components, which is applied to vehicle parts, transportation and packaging, film/sheet adhesives, etc., can solve the problem of vehicle component hardening, achieve simple processing and fixing, and reduce manufacturing time and personnel input , to reduce the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

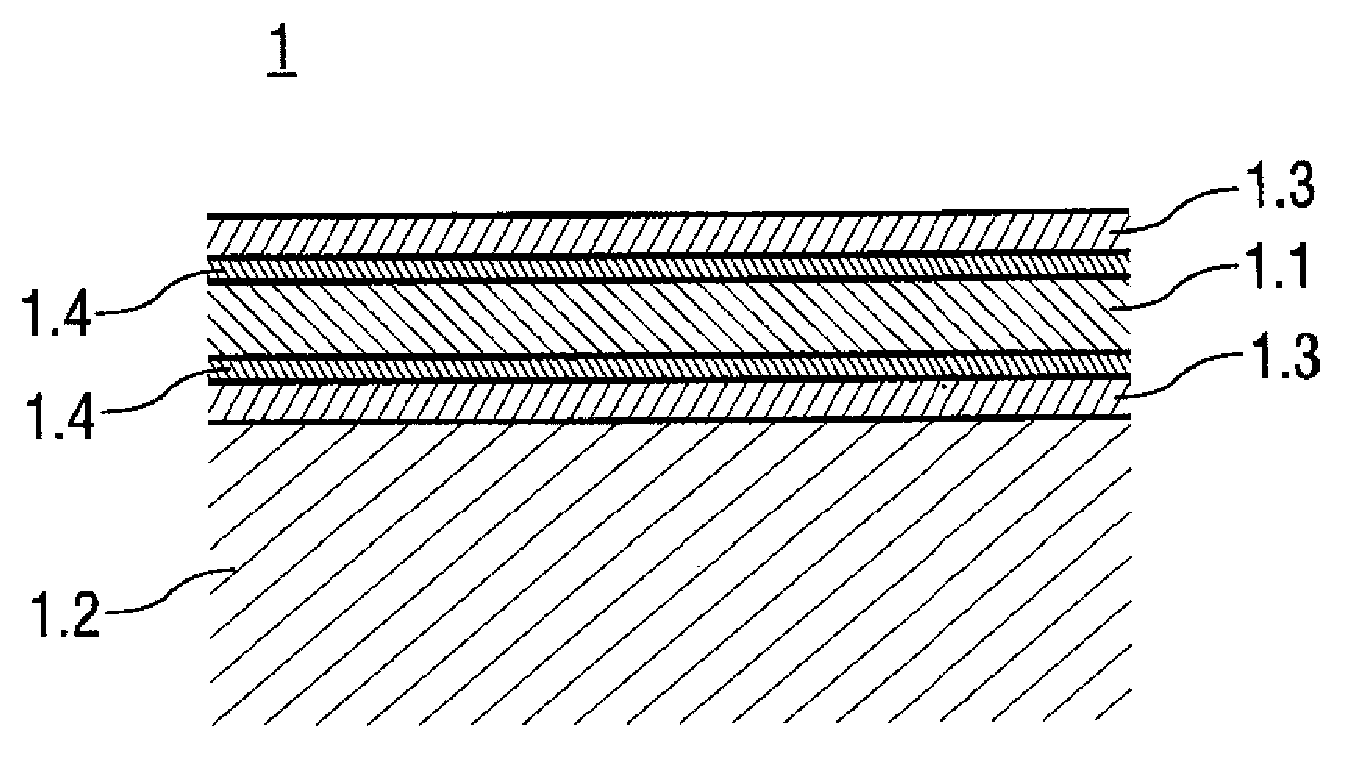

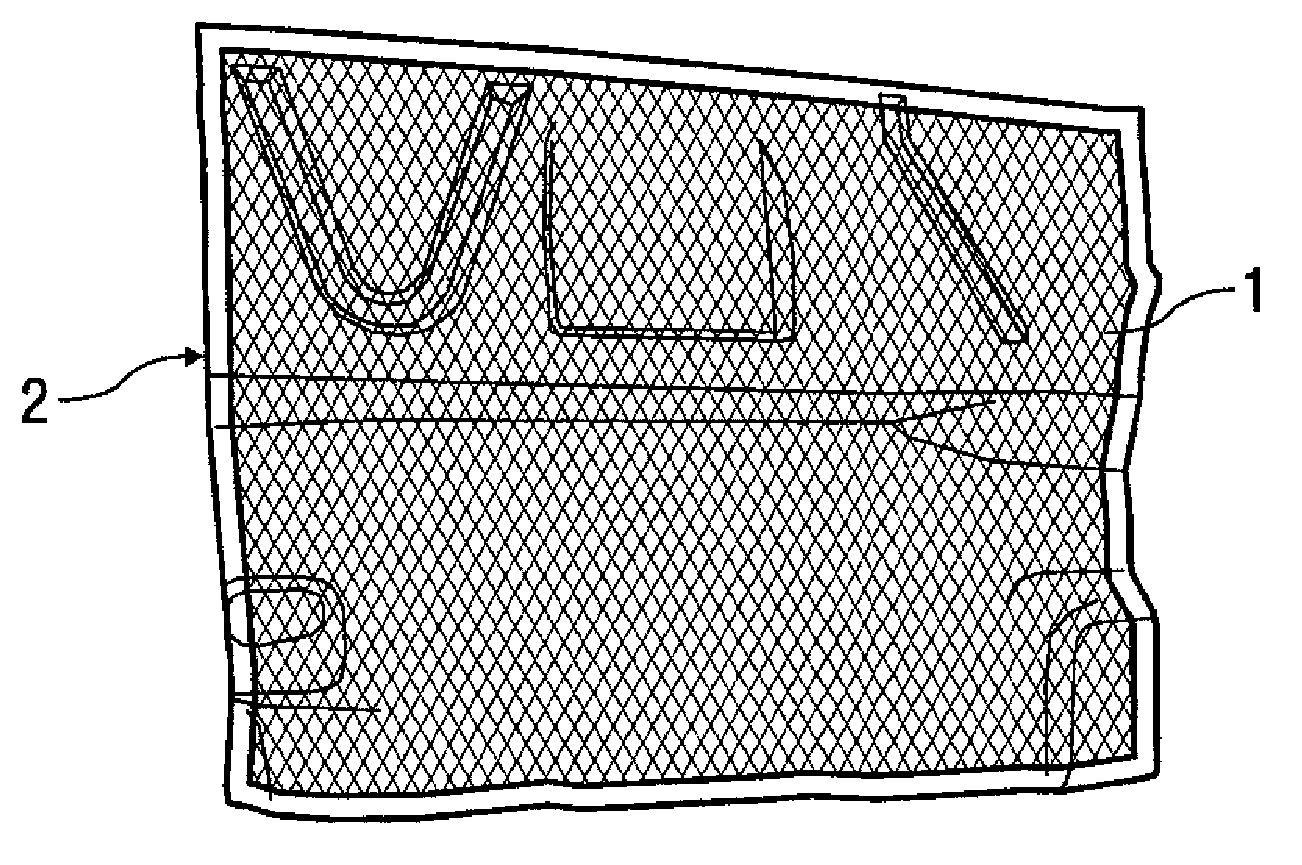

[0017] exist figure 1 A sound-insulating or damping element 1 according to the invention (which will hereinafter be referred to as a damping element because said element has essentially damping properties and only partially sound-insulating properties) is described in . The damping element 1 is designed as an adhesive element, which is formed in multiple layers from a carrier layer 1.1 and a self-adhesive damping mass 1.2.

[0018] Such a damping element is known in principle from DE 10 2008 050 772 A1. However, the damping element is used here mainly for another purpose, namely to close the opening in the motor vehicle body.

[0019] In a particularly preferred configuration, the carrier layer 1.1 is formed from a so-called 5xxx aluminum alloy which has a magnesium content of 0.2% to 6.2%. 5xxx aluminum alloys are characterized by a high strength, which lies at 100 N / mm 2 to 450N / mm 2 in the range.

[0020] Instead of using a 5xxx aluminum alloy, the carrier layer 1.1 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com