Overhauling tool for live working of 750kV transmission line

A technology for live work and maintenance tools, applied in the direction of overhead lines/cable equipment, etc., which can solve the problems that operators cannot bear high energy consumption, cannot reach clamps, and cannot complete maintenance operations, etc., so that it is not easy to twist and deform, The effect of taking up less space and reducing the time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

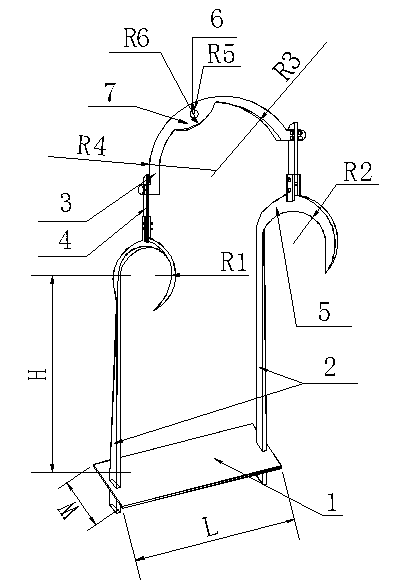

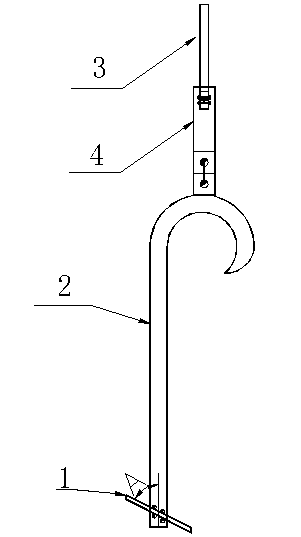

[0011] The present invention will be described in detail below with reference to the accompanying drawings. like figure 1 Shown: a 750kV high-altitude live working maintenance tool for transmission lines, including a base platform 1, two insulator brackets 2 and a lifting bracket 3, the lower parts of the two insulator brackets 2 are located at the left and right ends of the base platform 1, and the insulators The upper end of the bracket 2 is provided with an arc-shaped bracket 5, the upper end of the bracket 5 is connected to the left and right ends of the lifting bracket 3 through the connecting arm 4, and the center of the lifting bracket 3 is provided with a downward protrusion 7. Lifting 7 places are provided with lifting eyelet 6, and projection radius R6 is 400mm, and lifting eyelet radius R5 is 18mm. Lifting eyelet 6 is used for overhaul tool to pass.

[0012] The arc of the arc-shaped holder 5 is adapted to the size of the insulator, the arc radius R1 of the arc-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com