Peripheral sealing framework of photovoltaic module

A photovoltaic module, photovoltaic technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of reduced component life, waste, short life of rubber strips, etc., to reduce weight and cost, reduce production costs, and save human and financial resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment is a sealing frame around the photovoltaic module, which is composed of a short frame or a long frame, or a combination of a long frame and a short frame. The long frame and the short frame can be used alone or in combination on the photovoltaic module. It is even used in a 3+1 manner (that is, one long or short frame is used for three sides, and another short or long frame is used for the remaining side), and the matching degree is extremely high.

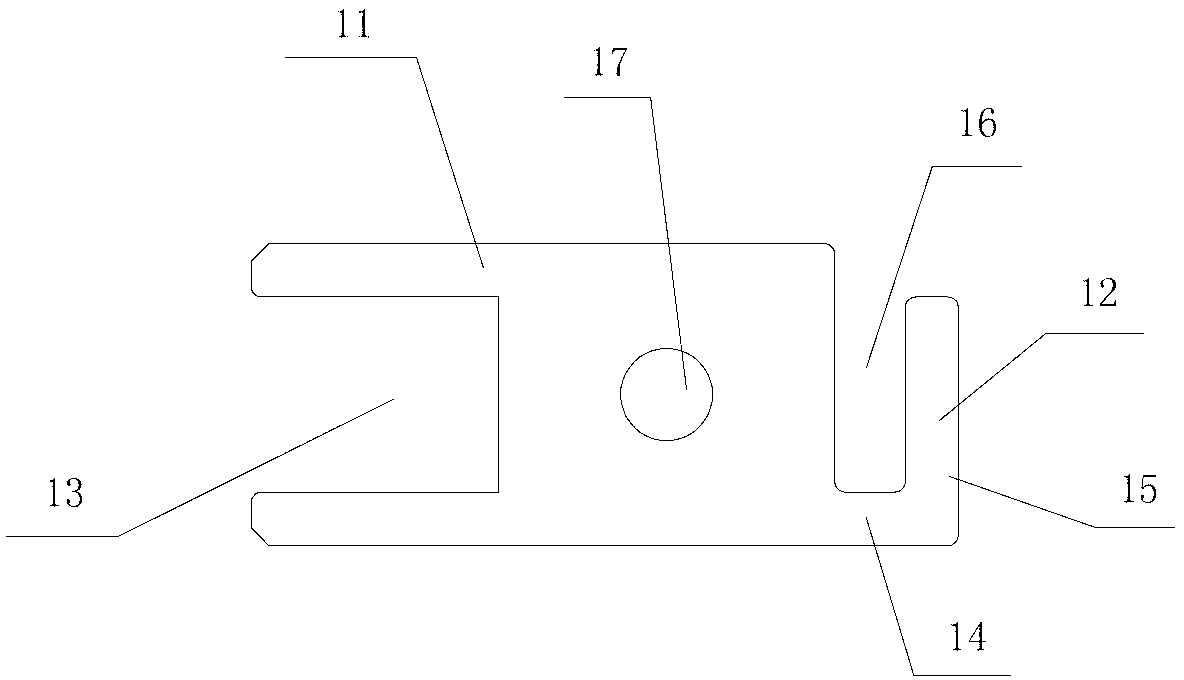

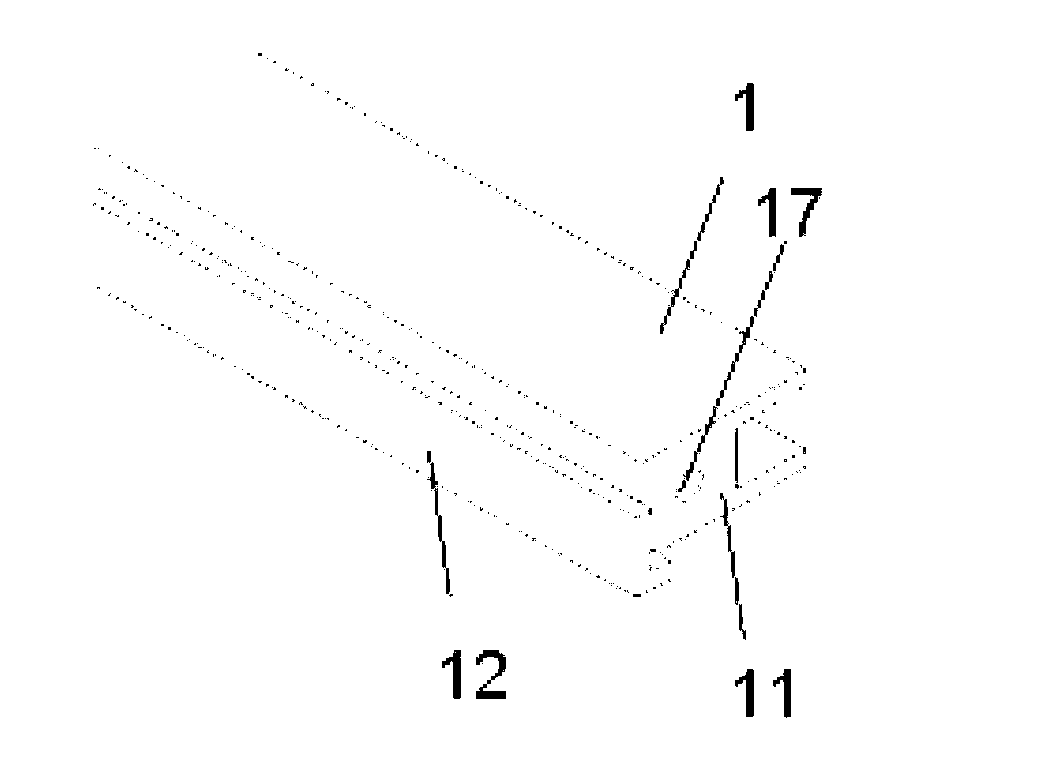

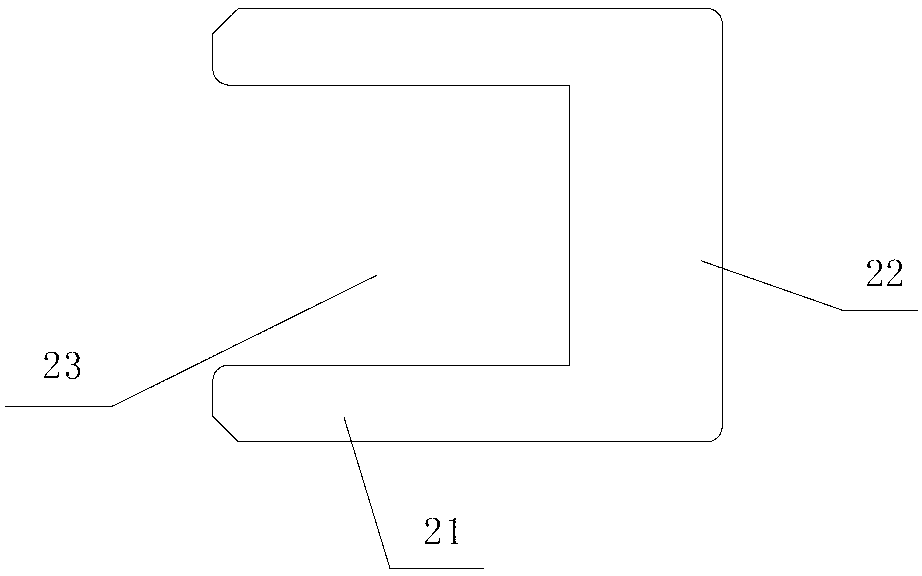

[0028] Short frame structure such as figure 1 and figure 2 As shown, the short frame 1 includes a first concave profile 11 and an L-shaped profile 12, the first concave profile 11 and the L-shaped profile 12 are integrally formed; the groove 13 of the first concave profile is located on one side thereof, The other side of the first concave-shaped profile connects the short side 14 of the L-shaped profile and forms a U-shaped groove 16 with the long side 15 of the L-shaped profile. The bottom surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com