X-ray flat panel detector and manufacturing method thereof

A flat-panel detector and X-ray technology, applied in radiation control devices, etc., can solve the problems of increasing process complexity and manufacturing costs, reducing spatial resolution, and inability to integrate transistors, so as to improve image quality and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

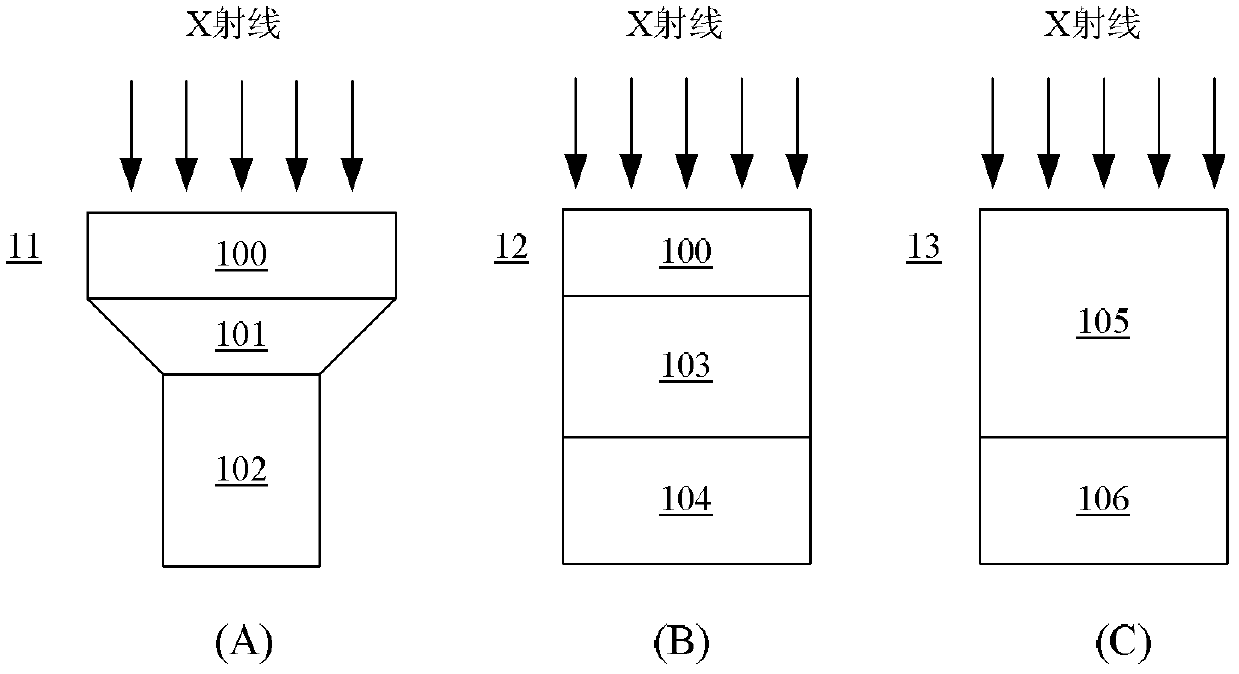

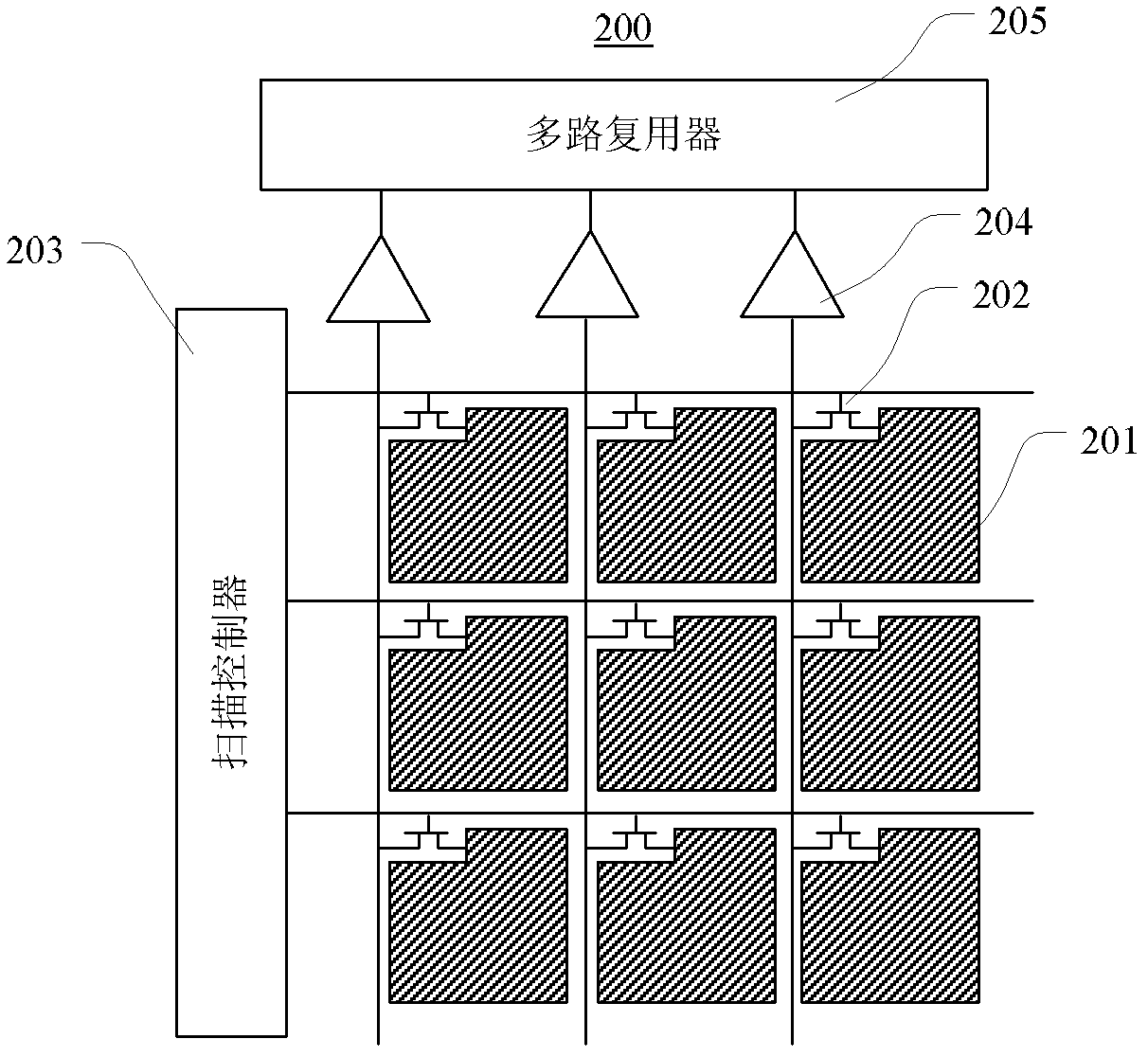

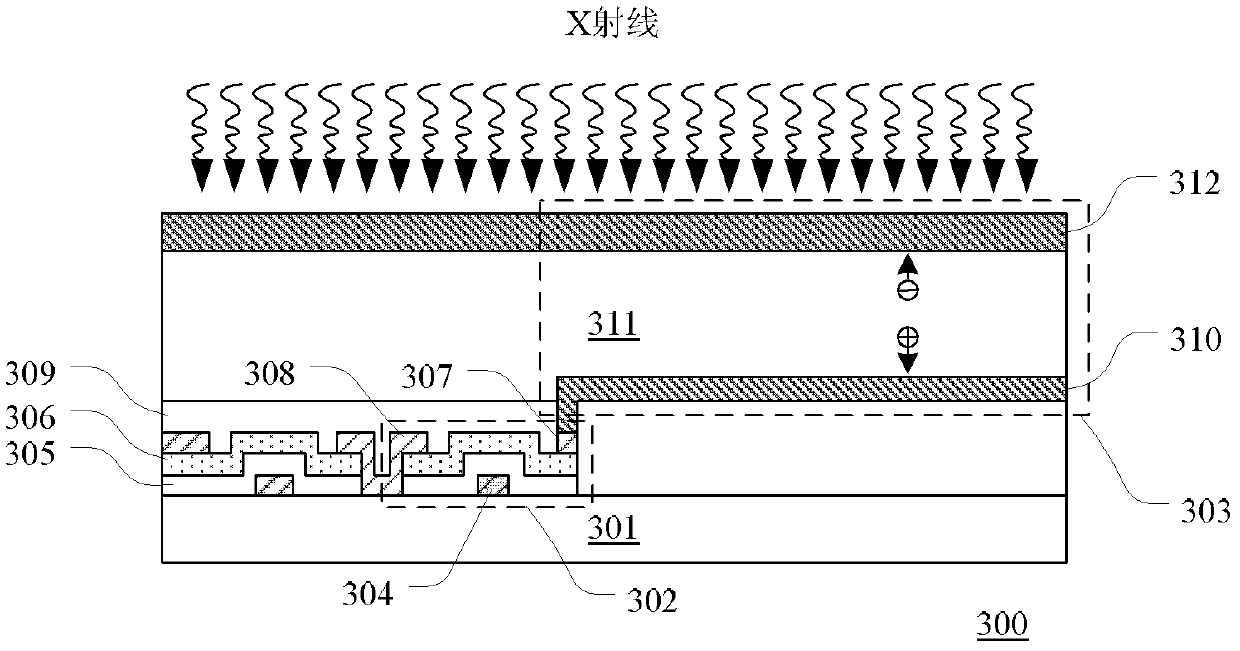

[0023] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. In the various drawings, for the sake of clarity, various parts in the drawings are not drawn to scale.

[0024] In the following, many specific details of the present invention are described, such as device structures, materials, dimensions, processing techniques and techniques, for a clearer understanding of the present invention. However, the invention may be practiced without these specific details, as will be understood by those skilled in the art. Unless otherwise specified below, various parts in the semiconductor device may be composed of materials known to those skilled in the art.

[0025] In the present application, the term "semiconductor structure" refers to a semiconductor substrate formed after undergoing various steps of manufacturing a semiconductor device and all layers or regions that have been formed on the semiconductor substrate.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com