Photoelectric module performance test device and test method in high temperature environment

A technology for photoelectric modules and high-temperature environments, which is applied in the direction of measuring devices, lamp testing, and measuring electricity, and can solve problems such as reliability distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

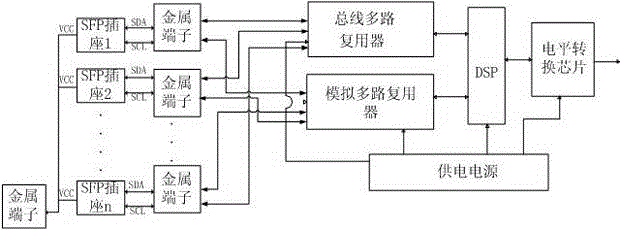

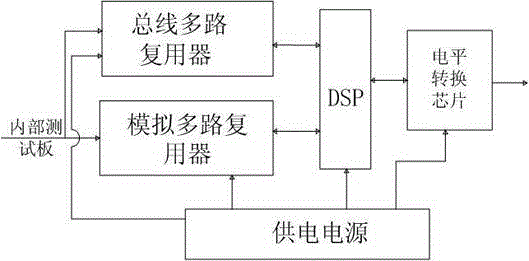

[0061] like Figures 1 to 3As shown, the photoelectric module performance test device under the high temperature environment of the present invention, the photoelectric module performance test device under the high temperature environment, comprises a high temperature oven, an internal test board is installed in the high temperature oven, and an external test board, the internal test board and the external test board Connection, the output signal of the external test board is transmitted to the computer; the internal test board includes an SFP socket, the SDA, SCL, VCC three pins of the SFP socket are connected to the metal terminal, the SDA bus and the SCL bus are connected to the optical module to achieve reading communication, VCC Provide stable power. There are n SFP sockets, n is a natural number greater than 1, and the n SFP sockets are respectively connected to the I2C bus multiplexer and the analog multiplexer. The multiplexer adopts the ADG506AKR model, and the I2C b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com