Taper bearing installation method using taper bearing test tool

A bearing test and installation method technology, applied in the direction of mechanical bearing test, mechanical device, measuring device, etc., can solve the problems of complex structure, pre-tightening error, insufficient assembly accuracy, etc., to achieve accurate measurement data, improve service life, The effect of accurate measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

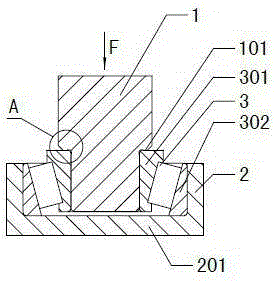

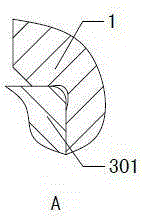

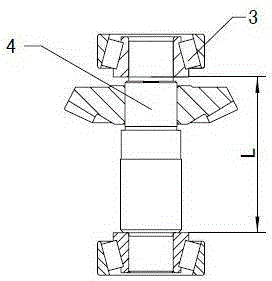

[0026] Figure 1~3 It is the best embodiment of the installation method of the taper bearing test tooling and the taper bearing of the present invention, below in conjunction with the attached Figure 1-5 The present invention will be further described.

[0027] Refer to attached Figure 1~2 : The tapered bearing test tooling includes a final shaft 1 and a cylindrical seat 2. The final shaft 1 is a stepped circular shaft with an upper diameter greater than that of the lower part. The middle part forms a right-angled step 101. The connection between the lower circumference of the final shaft 1 and the step 101 is a concave rounded corner. , which can ensure that the rounded corner of the final shaft 1 will not contact the rounded corner of the tapered bearing 3 . The upper part of the cylindrical seat 2 is open, and the bottom is integrally provided with a disc-shaped pressure bearing plate 201 .

[0028] The relative displacement X of the inner and outer rings 301, 302 of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com