Electrode displacement monitoring device and method for resistance spot welding and resistance spot welding device

A technology of resistance spot welding and monitoring device, applied in the direction of measuring device, instrument, etc., can solve the problems of increased cost, amplification and error accumulation of sensing and measuring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

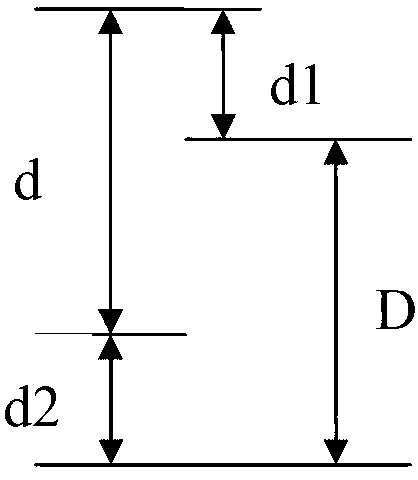

[0027] The core of the present invention is to provide a monitoring device for electrode displacement, so as to accurately detect the variation of electrode displacement during the resistance spot welding process, and ensure accurate evaluation of nugget quality of welding spot.

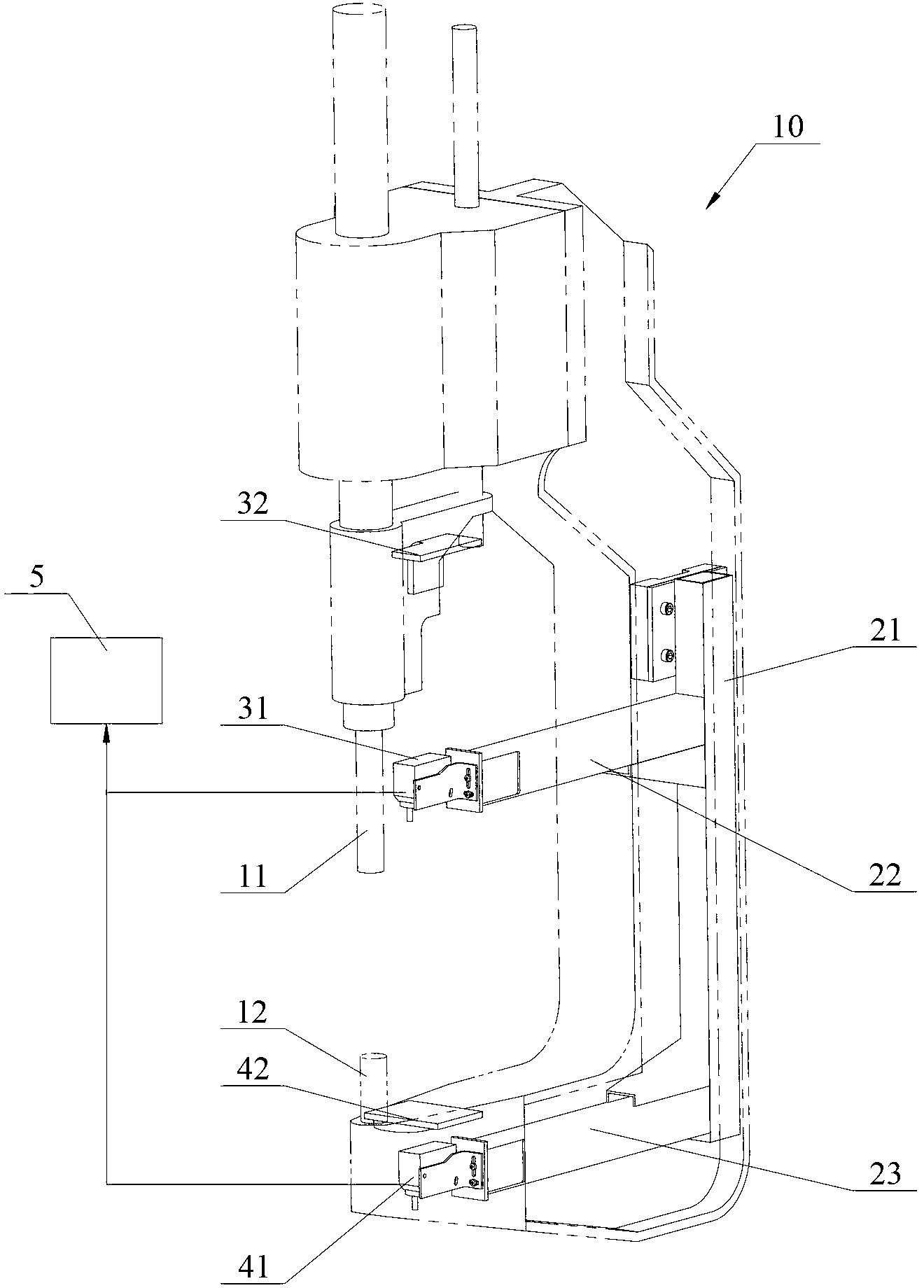

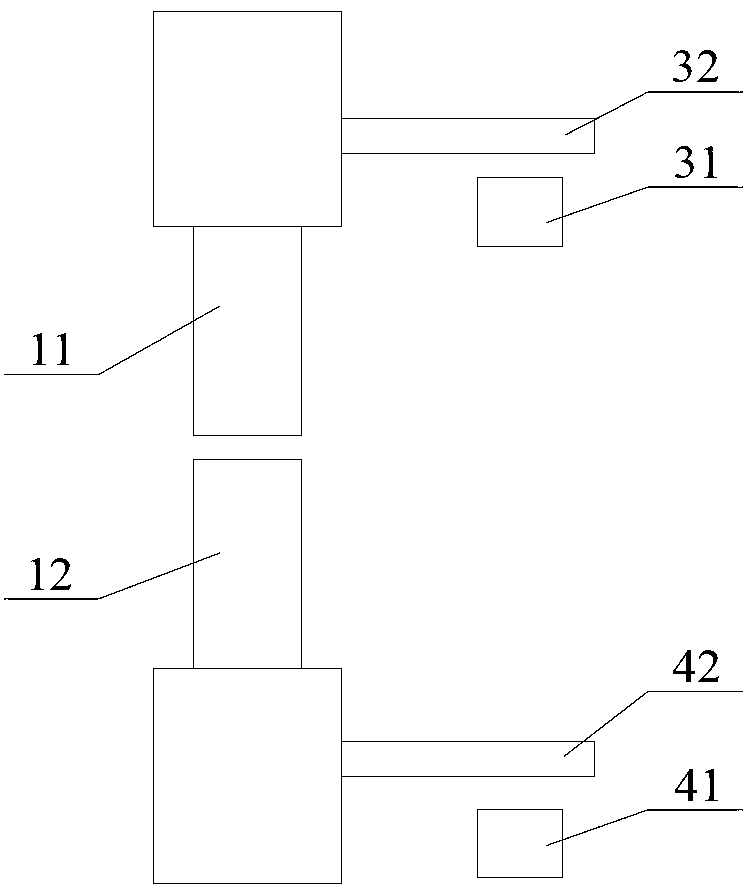

[0028] Without loss of generality, the present embodiment will be described in detail by taking the C-type welding tongs as an example in conjunction with the accompanying drawings below, that is, the C-type welding tongs 10 will be used as the welding equipment substrate for detailed description; the same as the prior art, the upper electrodes 11 and The lower electrodes 12 are respectively connected to the opening side of the C-shaped welding tongs through the holding parts, so as to facilitate welding.

[0029] See figure 1 , which is an axonometric schematic diagram of the assembly relationship between the electrode displacement monitoring device and the resistance spot welding equipment describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com