Double-pipe petroleum screen

A technology for oil screens and oil pipelines, which is applied in the fields of mining fluids, wellbore/well components, and earthwork drilling and production, and can solve problems such as short service life, poor filtering function, and unsatisfactory performance, and achieve strong filtering effect and reasonable structure , The effect of convenient use conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

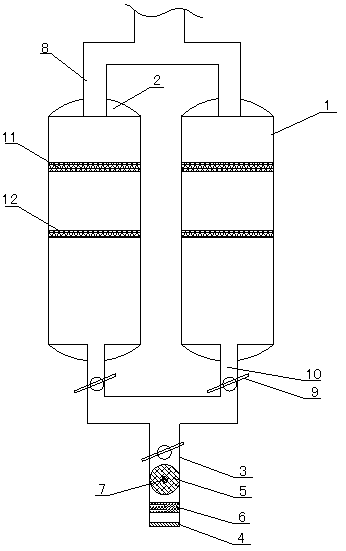

[0011] like figure 1 As shown, the double-pipe petroleum screen described in the embodiment of the present invention includes two filter inner cores 1 arranged side by side under the oil pipeline. The upper end of the filter inner core 1 is connected to a shunt pipe 8 led from the oil pipeline, and the lower ends of the two filter inner cores 1 are respectively connected to the collecting pipe 10 through a section of branch pipe. The collecting pipe 10 is vertically connected to a filter pipe 3, located A rotating filter ball 5 is installed inside through a rotating shaft 7, and a buckle cover 4 is provided at the outer end of each filter tube 3, and a mesh filter belt 6 is added in the lumen between the rotating filter ball 5 and the buckle cover 4, At the same time, the inside of the filter core 1 is sequentially provided with a first-stage filter screen 11 and a second-stage filter screen 12 from top to bottom, and the second-stage filter screen 12 is arranged at the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com