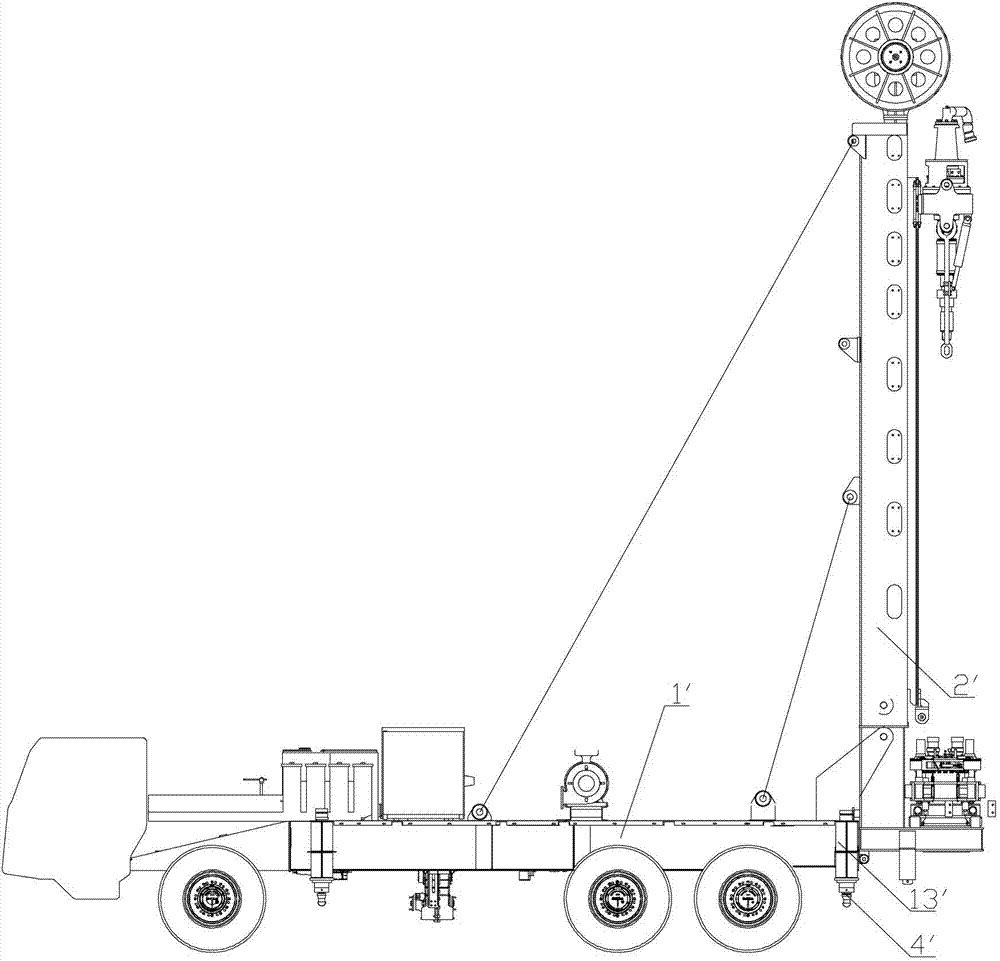

Drilling rig and rig frame thereof

A frame and drilling rig technology, applied in the field of construction machinery, can solve the problems of large overall weight, uneven force on the frame 1', and high manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

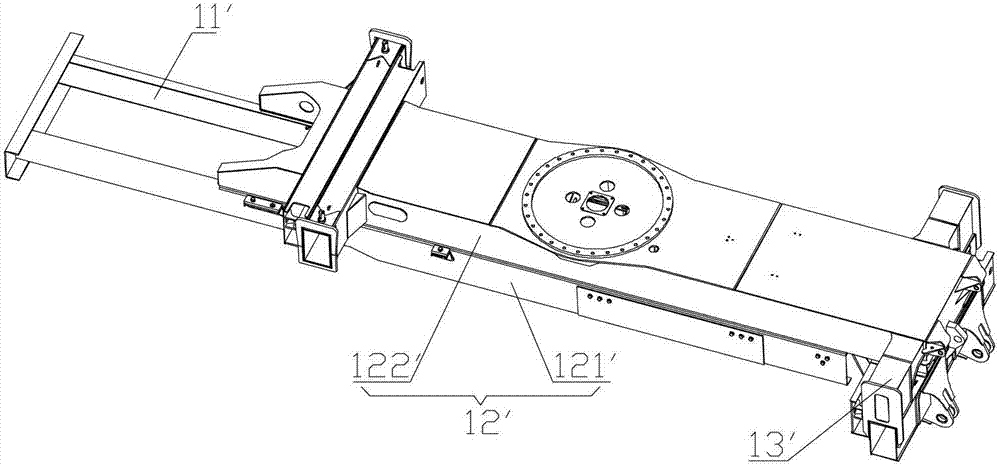

[0053] The core of the present invention is to provide a drilling rig and its frame. By designing the rear part of the frame with an integral box-shaped structure, instability such as misalignment is avoided, the moment of inertia of the cross section is improved, and the Reduce the weight of the frame without sacrificing strength and rigidity.

[0054] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0055] It should be noted that the orientation word "transverse" in this article refers to the width direction of the frame, and "inside" refers to the direction from the lateral sides of the frame to its longitudinal centerline, that is, Figure 7 The left and right ends point to the direction of the center, and the "outside" refers to the direction from the longitudinal centerl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com