Novel direct-discharging type closestool blowdown system and novel non-water-tank closestool flushing system

A sewage system and direct discharge technology, which is applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of complex structure, waste of resources and time, and failure to achieve the effect of water storage and deodorization. Simple structure and improved production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

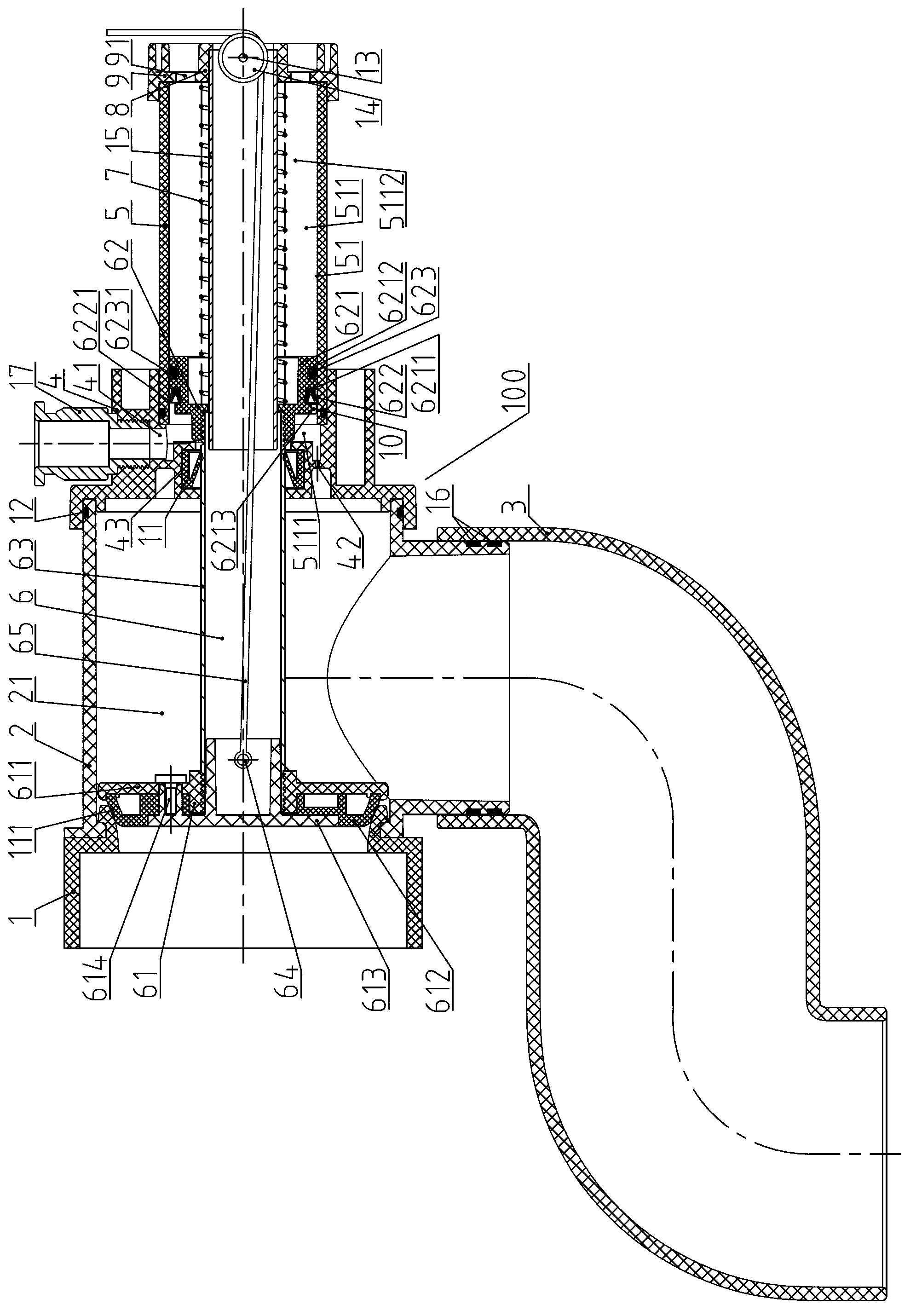

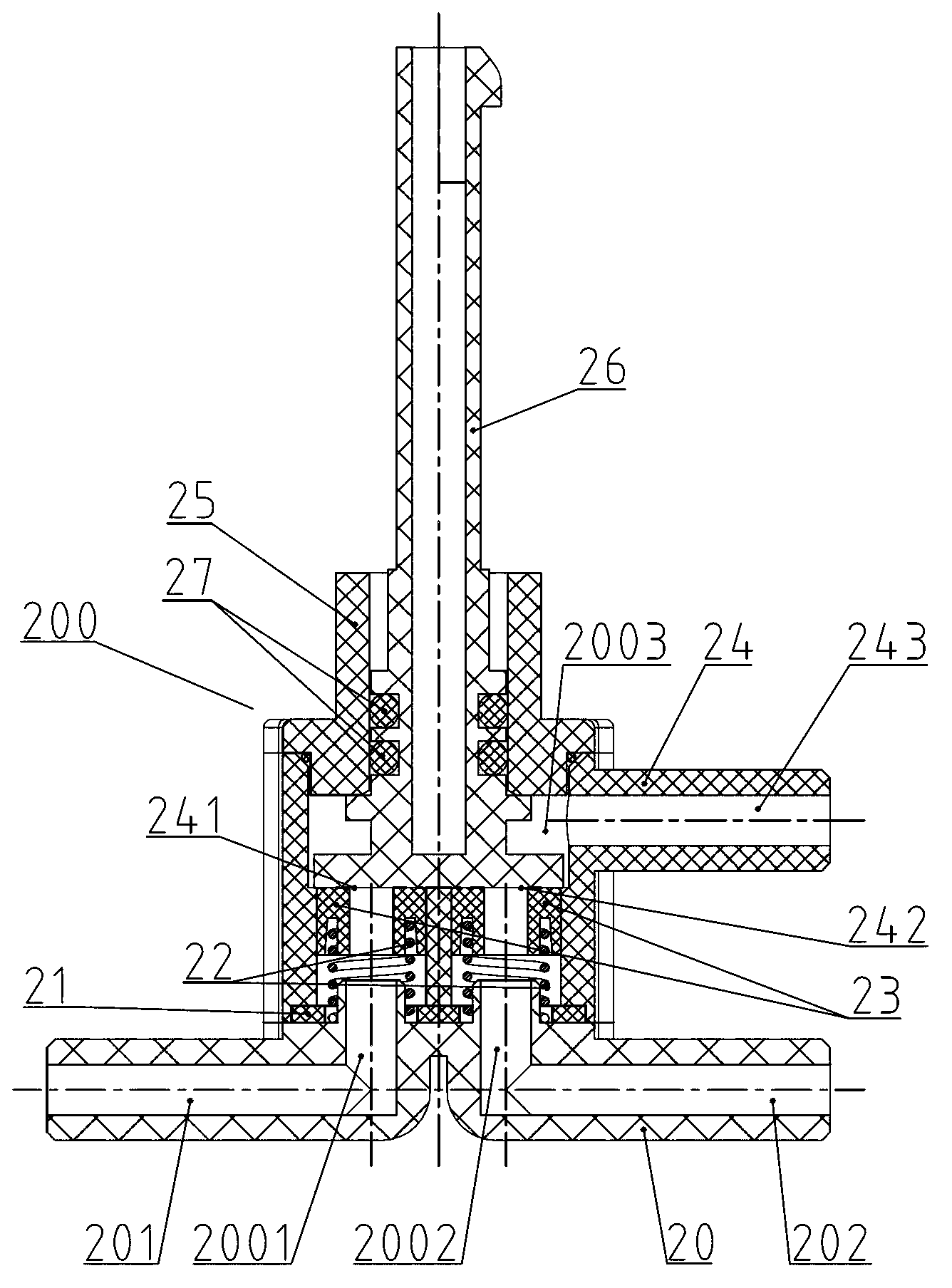

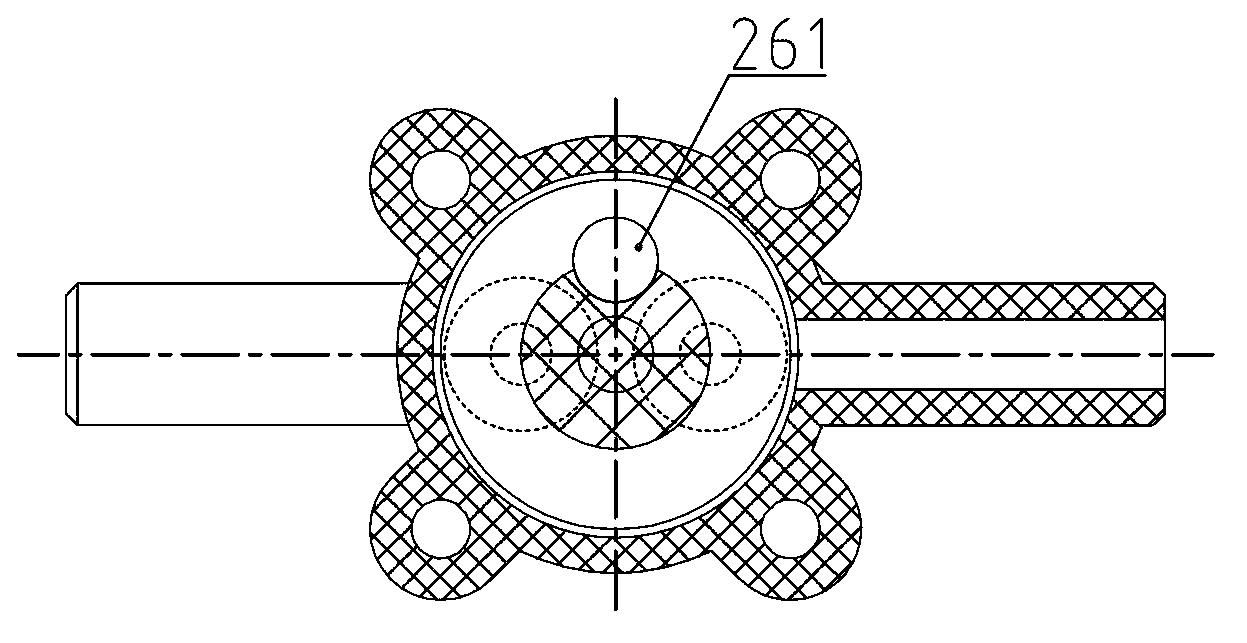

[0036] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 — Figure 5 ;

[0037] In this embodiment, for the convenience of describing the position relative to the piston assembly, the orientation of the hydraulic chamber is defined as the left side, and the orientation of the air chamber relative to the position of the piston assembly is defined as the right side.

[0038] The novel straight toilet sewage system 100 includes a sealing ring 1 connecting the sewage outlet, a sewage pipe I2, a cylinder head I4, a cylinder body 5, a piston assembly 6, a spring 7, and a spring supporting part 8. Wherein, the piston assembly 6 includes a sewage outlet piston assembly 61 , a cylinder piston assembly 62 , and a piston connecting pipe 63 . The cylinder head I4 has a water inlet 41, a drainage hole 42 and a groove 43; the cylinder body and the cylinder head I form a sealed connection, specifically, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com