Mounting, burying and grouting method for multi-point displacement meter

A technology of displacement meter and grouting, which is applied in the field of foundation soil survey, construction, infrastructure engineering, etc. It can solve the problem of insufficient grouting and achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

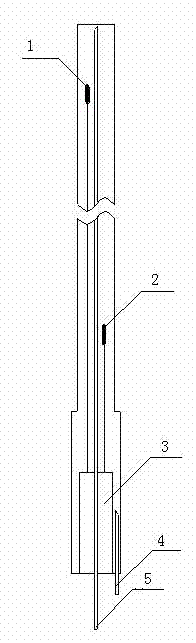

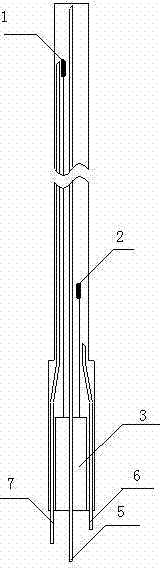

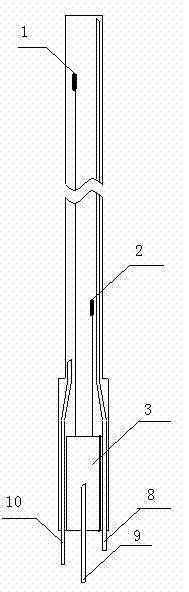

[0012] like Figure 4 As shown, displacement gauges are installed at multiple points in the tunnel rock formation, including horizontal direction, vertical direction, upward slope, and downward slope for rock displacement monitoring. The displacement gauge adopts double grouting method, that is, the displacement gauge is equipped with an exhaust pipe , Distal anchor head and proximal anchor head, double grouting tube. For vertical holes and upwardly inclined holes, the first grouting pipe in the displacement meter is installed one meter inside the hole, the second grouting pipe is installed at the distal anchor head, and the exhaust pipe is one meter beyond the distal anchor head. And make several side holes within 20cm from the top of the exhaust pipe, such as figure 2 As shown; for horizontal holes and downwardly inclined holes, the first grouting pipe in the displacement meter is installed one meter beyond the distal anchor head, the second grouting pipe is installed at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com