Positioning device and method of overall puncture module equidistance densely-arrayed micro holes

A technology of integral puncture and puncture template, which is applied in deburring devices, textiles and papermaking, fiber processing, etc. It can solve the problems that the microhole array cannot be used for positioning and is not applicable, and achieves simple structure and working control principle, low cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in further detail below in conjunction with specific embodiments.

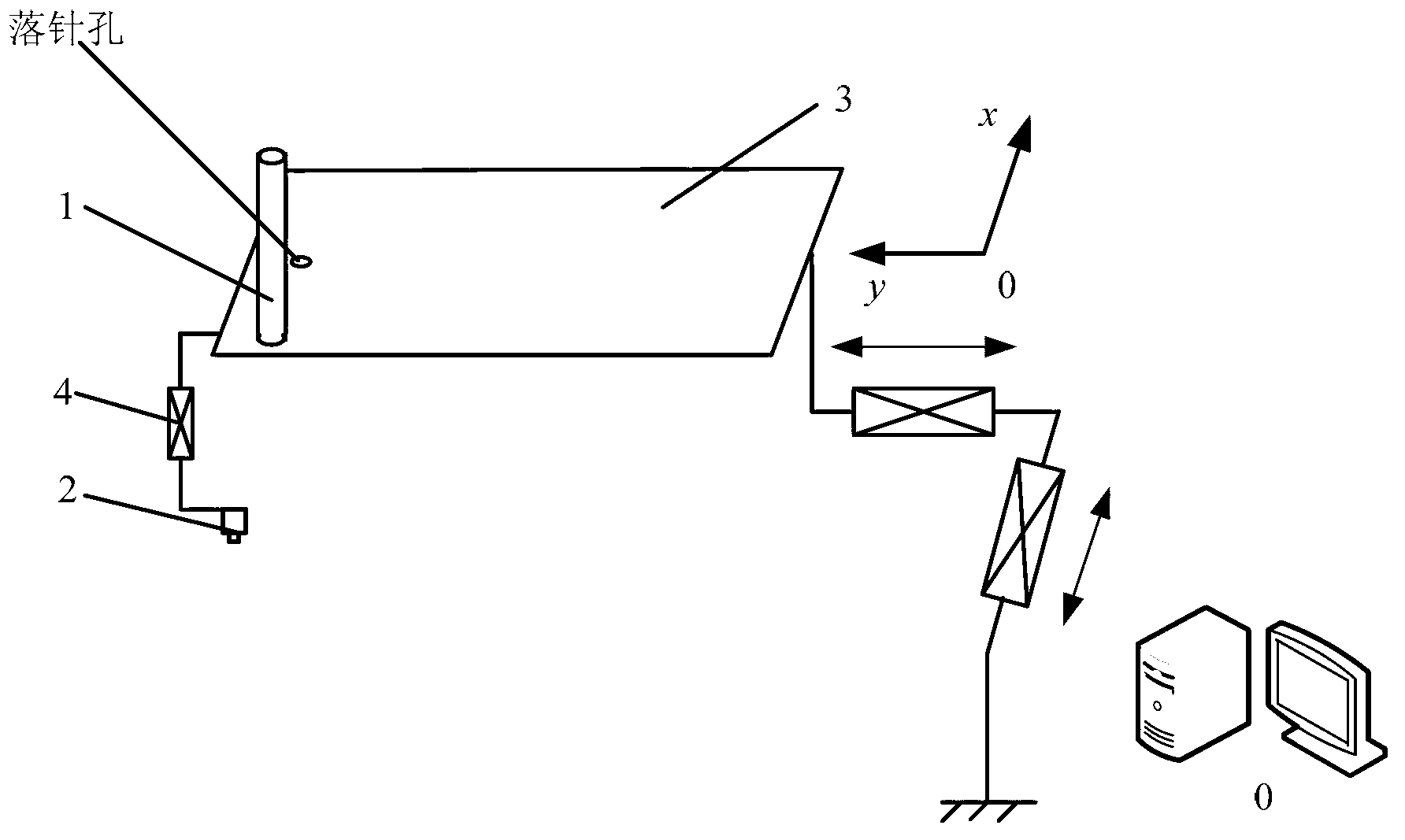

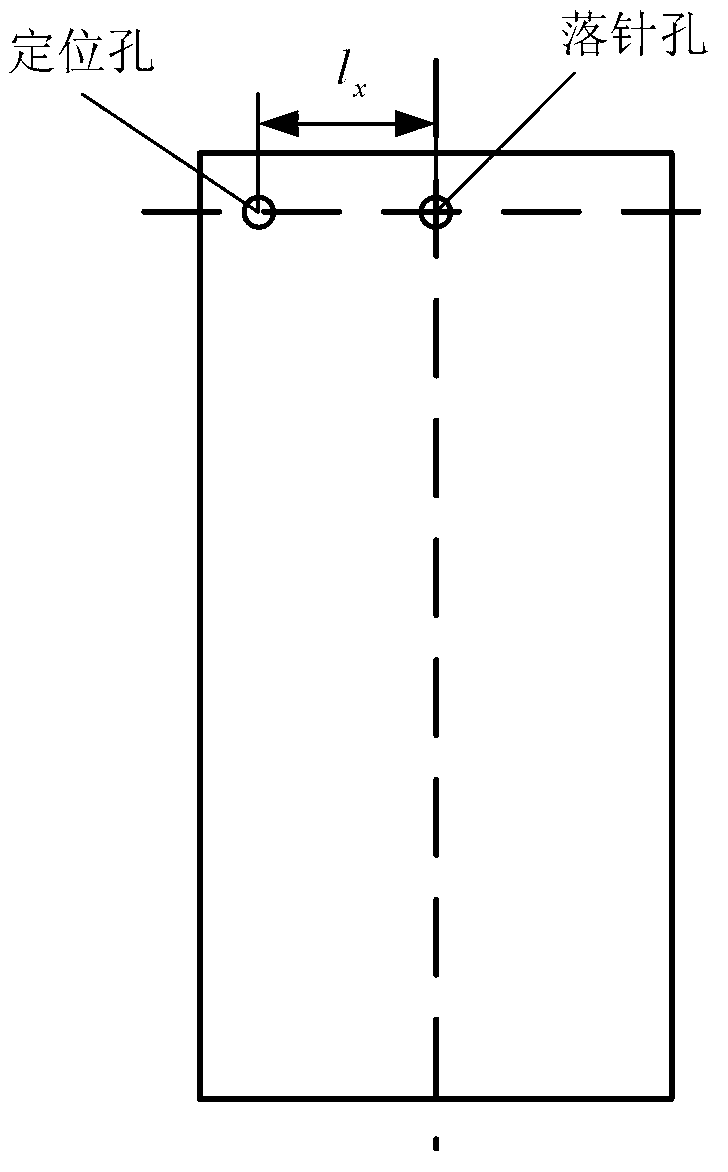

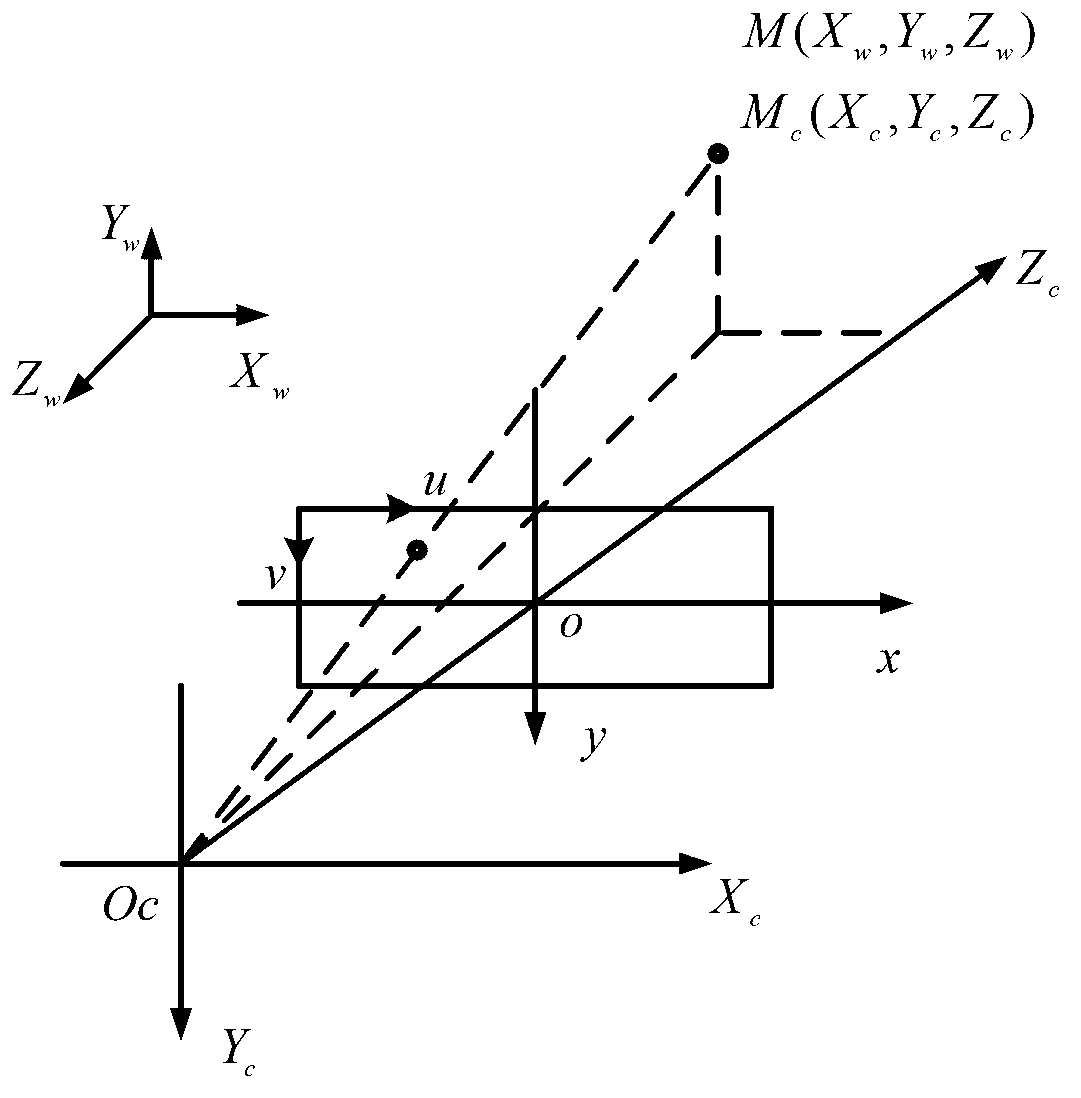

[0044] Such as figure 1 As shown, an integral puncture template isometric close-packed micro-hole positioning device of the present invention includes an industrial PC 0, a needle arrangement mechanism, a red cross laser 1 and a miniature CCD camera 2, such as Figure 5 As shown, a video capture card 01 is inserted into the slot of the industrial PC 0, and the needle arrangement mechanism includes a bottom plate 3, which can move X-Y, such as figure 2 As shown, the bottom plate 3 is provided with a positioning hole, a pin drop hole and a telescopic connecting rod. The positioning hole is used to determine the position of the red cross laser 1 and the distance between the positioning hole and the pin drop hole It is an integer multiple of the puncture template hole spacing; the miniature CCD camera 2 is arranged at the end of the telescopic link 4, the red cross laser ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com