Horizontal type multi-target vacuum sputtering or ion plating machine

A technology of vacuum sputtering and coating machine, which is applied in the direction of sputtering coating, ion implantation coating, vacuum evaporation coating, etc., and can solve problems such as the effect of barrel plating on difficult workpieces, poor adaptability of coated parts, and environmental pollution. , to achieve the effect of improving the quality of the coating of the workpiece, making it easy to enter and exit, and improving the quality of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

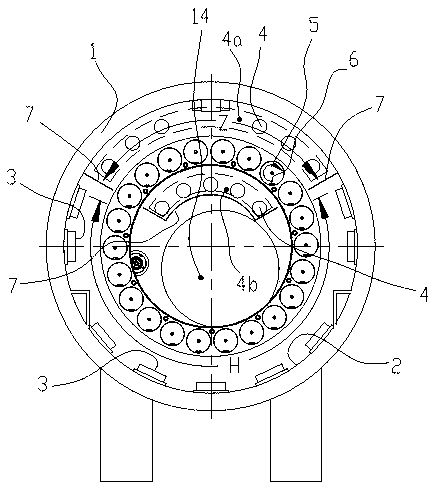

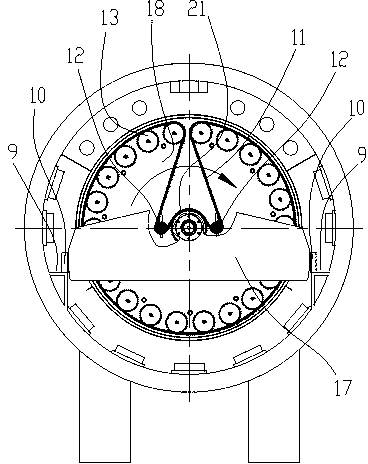

[0026] like figure 1 , figure 2 As shown, the inner wall 2 of the furnace body of the coating machine is divided into two areas, a plurality of arc targets 3 are arranged in area 1 H, and are arranged under the furnace body 1 of the coating machine, and a plurality of sputtering targets 4 are arranged in area 2 Z, and are arranged in the coating machine The top of furnace body 1.

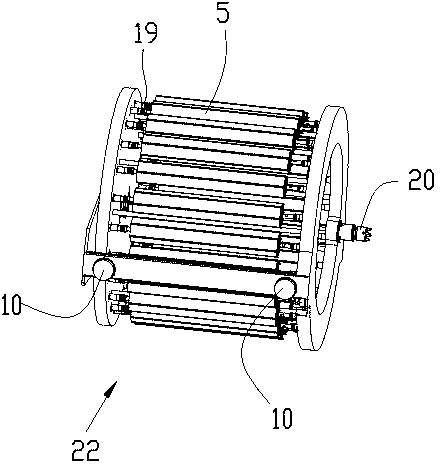

[0027] The sputtering target 4 is a cylindrical structure and can rotate around the axis of the cylinder.

[0028] The sputtering targets 4 are divided into two groups arranged oppositely, one group of sputtering targets 4a is close to the inner wall 2 of the furnace body of the coating machine, and the other group of sputtering targets 4b is set on the coating machine corresponding to the hollow position of the workpiece holder 22 above the center of the coating machine f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com