ABS/PET composite antibacterial material and preparation method thereof

A technology of compounding antibacterial and antioxidant, applied in the field of engineering material manufacturing, can solve the problem of rare antibacterial materials, and achieve the effect of excellent antibacterial properties and good physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

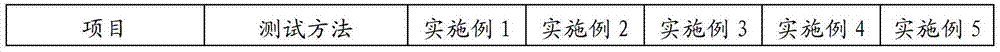

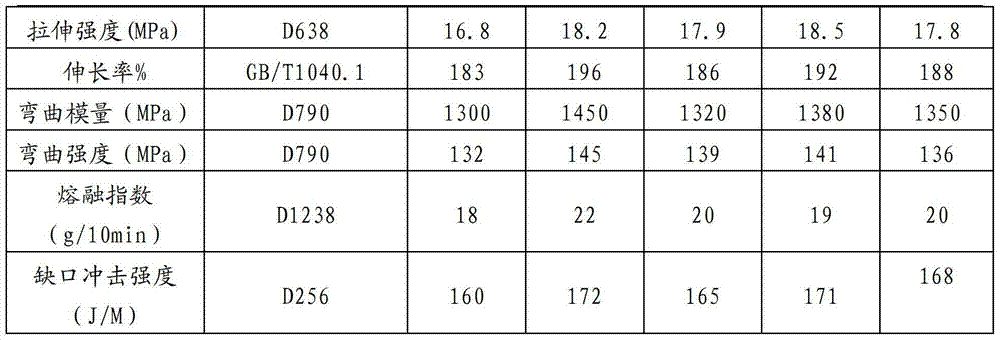

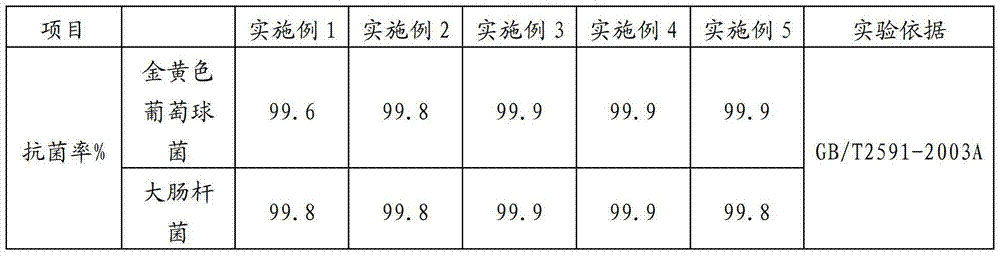

Examples

Embodiment 1

[0028] A kind of ABS / PET composite antibacterial material, is made up of the component of following parts by weight:

[0029] 50 copies of ABS;

[0030] PET45 copies;

[0031] PP-g-MAH 10 parts;

[0032] 5 parts of styrene-butadiene thermoplastic elastomer;

[0033] 1 part of pentaerythritol ester;

[0034] 0.5 part of diester of thiodipropionate;

[0035] Chitin 0.1 part;

[0036] 0.2 parts of nano zinc oxide powder;

[0037] 0.2 parts of nano-silver powder;

[0038] 0.3 parts of 4-hydroxy-3-methoxy-benzaldehyde

[0039] Carry out the preparation of above-mentioned ABS / PET composite antibacterial material according to the following steps:

[0040] (1) Weigh the above components according to parts by weight

[0041] (2) Add the weighed components into the mixer and stir for 30 minutes at a speed of 80 rpm.

[0042] (3) Extrude and granulate the homogeneously mixed raw materials in a twin-screw extruder, wherein the processing temperature of the twin-screw extruder is...

Embodiment 2

[0044] A kind of ABS / PET composite antibacterial material, is made up of the component of following parts by weight:

[0045] ABS53 copies;

[0046] PET50 copies;

[0047] PP-g-MAH 12 parts;

[0048] 6 parts of styrene-butadiene thermoplastic elastomer;

[0049] 2 parts of pentaerythritol ester;

[0050] 0.8 part of diester of thiodipropionate;

[0051] Chitin 0.2 parts;

[0052] 0.3 parts of nano zinc oxide powder;

[0053] 0.3 parts of nano-silver powder;

[0054] 0.3 parts of 4-hydroxy-3-methoxy-benzaldehyde

[0055] Carry out the preparation of above-mentioned ABS / PET composite antibacterial material according to the following steps:

[0056] (1) Weigh each component according to parts by weight

[0057] (2) Add the weighed components into the mixer, and stir for 25 minutes at a speed of 90 rpm.

[0058] (3) Extrude and granulate the homogeneously mixed raw material in a twin-screw extruder, wherein the processing temperature of the twin-screw extruder is 310° C....

Embodiment 3

[0060] A kind of ABS / PET composite antibacterial material, is made up of the component of following parts by weight:

[0061] ABS60 copies;

[0062] PET53 copies;

[0063] PP-g-MAH 14 parts;

[0064] 8 parts of styrene-butadiene thermoplastic elastomer;

[0065] 3 parts of pentaerythritol ester;

[0066] 1 part of thiodipropionate diester;

[0067] Chitin 0.3 parts;

[0068] 0.4 parts of nano zinc oxide powder;

[0069] 0.4 parts of nano-silver powder;

[0070] 0.4 parts of 4-hydroxy-3-methoxy-benzaldehyde

[0071] Carry out the preparation of above-mentioned ABS / PET composite antibacterial material according to the following steps:

[0072] (1) Weigh each component according to parts by weight

[0073] (2) Add the weighed components into the mixer, and stir for 40 minutes at a speed of 120 rpm.

[0074] (3) Extrude and granulate the homogeneously mixed raw materials in a twin-screw extruder, wherein the processing temperature of the twin-screw extruder is 300° C., a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com