High-elasticity sneaker air cushion sole and production method thereof

A production method and technology of sports shoes, which are applied in the field of shoelace materials, can solve the problems of affecting the service life of sports shoes soles, reducing wearing comfort, easy deformation and shrinkage, etc., and achieve light weight, improved shockproof effect, and good elastic effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

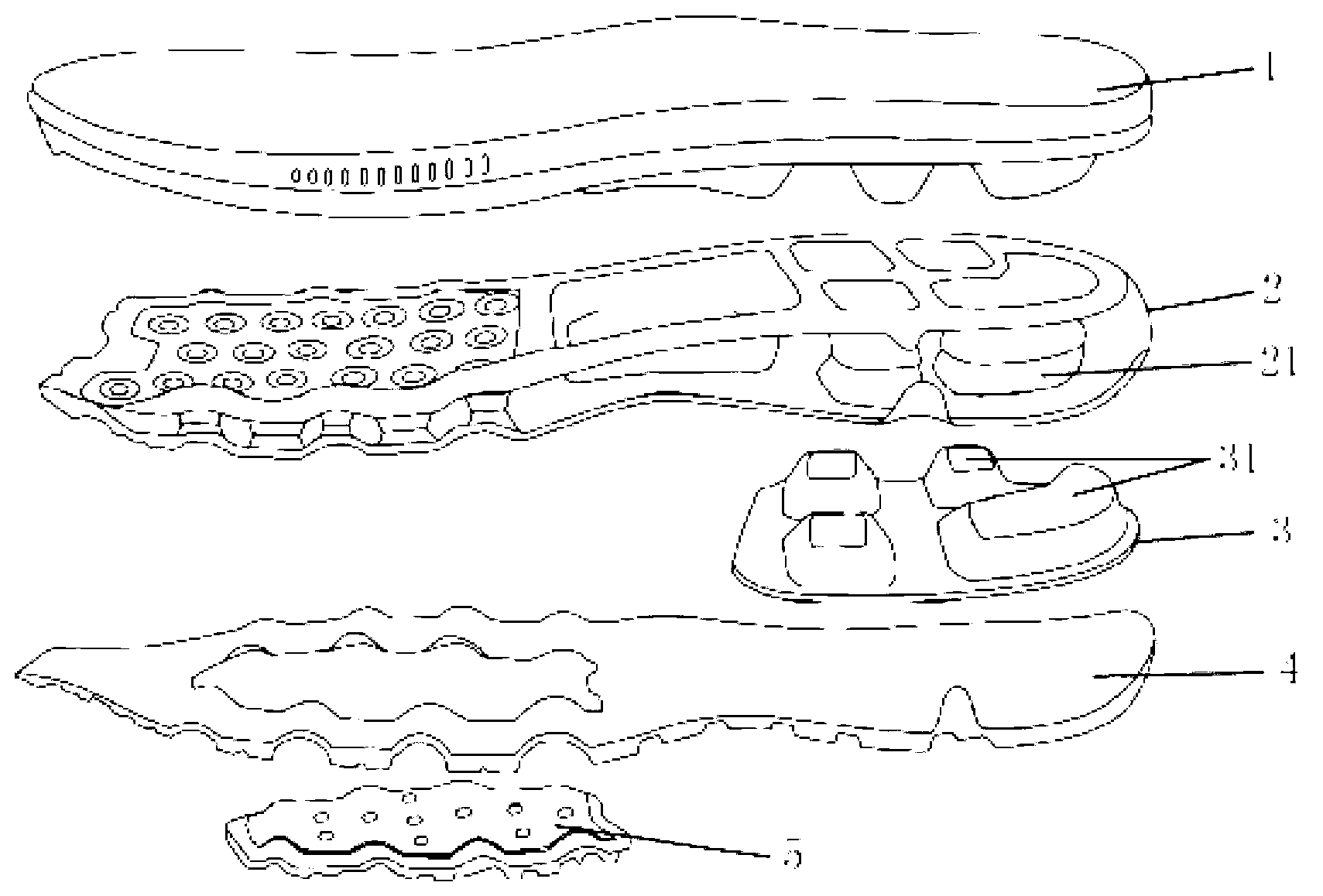

[0035] refer to figure 1 , a kind of highly elastic sports shoe air cushion sole, including MD midsole 1, air cushion 2 and outsole 4 fixedly connected sequentially from top to bottom, the heel of the air cushion 2 is equipped with an EVA spacer 3, and the inside of the air cushion 2 Filled with nitrogen gas, the bottom surface at the heel of the air cushion 2 is concaved to form several concave parts 21; the EVA gasket 3 is provided with several convex parts 31 adapted to the concave parts 21.

[0036] The components and weight ratios of the material formula of the MD midsole are as follows: EVA: 40-60, EPDM: 0-20, POE: 0-30, talcum powder: 0-10, foaming agent: 2.0~4.0, bridging agent: 0.6~1.0, zinc oxide desulfurizer: 1.0~2.0, stearic acid: 0.6~1.2, zinc stearate: 0.5~1.0, flow aid: 0.8~1.5, bridging aid : 0.3~0.8.

[0037] The blowing agent of the present invention is preferably azodicarbonamide. Azodicarbonamide is abbreviated as AC, and its molecular formula is C2H4N4O...

Embodiment 2

[0044] Select the following component materials according to the weight ratio: EVA: 45, EPDM 5, POE: 30, foaming agent: 2.8, bridging agent: 1.0, zinc oxide: 1.3, stearic acid: 0.8, stearin Zinc acid: 1.0, flow aid: 0.8, bridging aid: 0.8. According to the above method, the proportioning is made into a shoe sole material. After testing, its physical properties are as follows:

[0045] A. Hardness: 45°±2, B. Compression distortion: ≤40%, C: Folding resistance: normal temperature ≥100,000 times, low temperature (-20°C) ≥80,000 times, D, yellow resistance: ≥4 grades (white , light gray, etc.).

Embodiment 3

[0047] Select the following component materials according to the weight ratio: EVA: 50, EPDM rubber 10, POE: 20, talcum powder: 5, foaming agent: 3.0, bridging agent: 0.8, zinc oxide: 1.5, stearic acid : 0.6, zinc stearate: 0.8, flow aid: 1.2, bridging aid: 0.5. According to the above method, the proportioning is made into a shoe sole material. After testing, its physical properties are as follows:

[0048] A. Hardness: 48°±2, B. Compression distortion: ≤38%, C: Folding resistance: normal temperature ≥100,000 times, low temperature (-20°C) ≥80,000 times, D, yellow resistance: ≥4 grades (white , light gray, etc.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Decomposition temperature | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com