Plate transporter

A technology for handling devices and plates, which is used in transportation and packaging, stacking of objects, and de-stacking of objects, etc., can solve the problems of inconvenient use and operation, cumbersome maintenance process, large floor space, etc., and achieves low production cost and maintenance. Simple, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

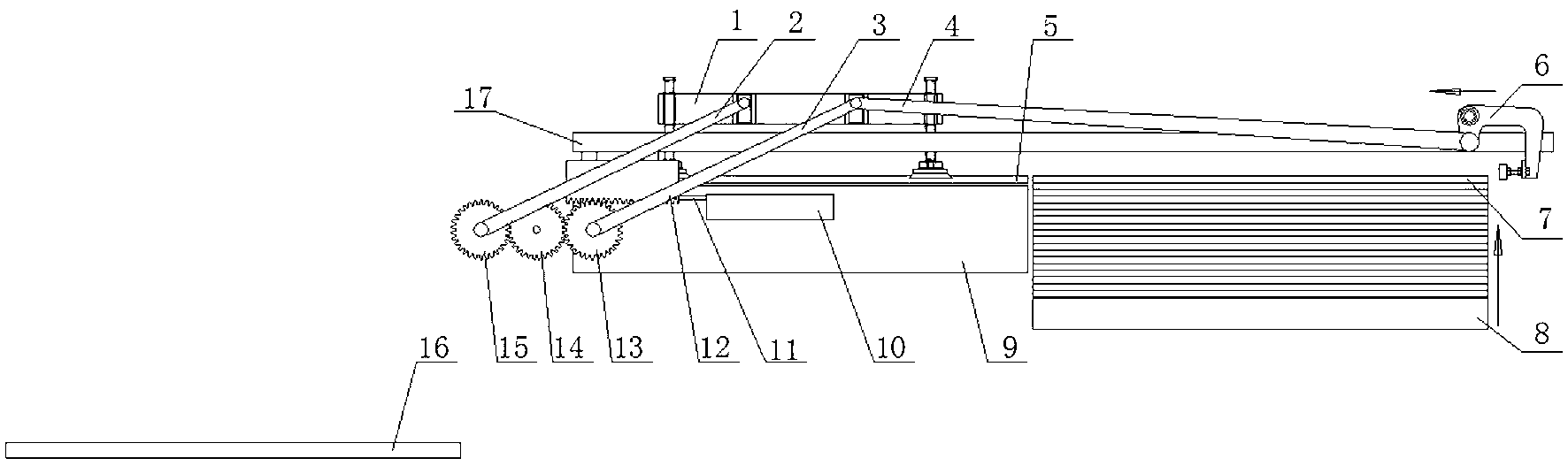

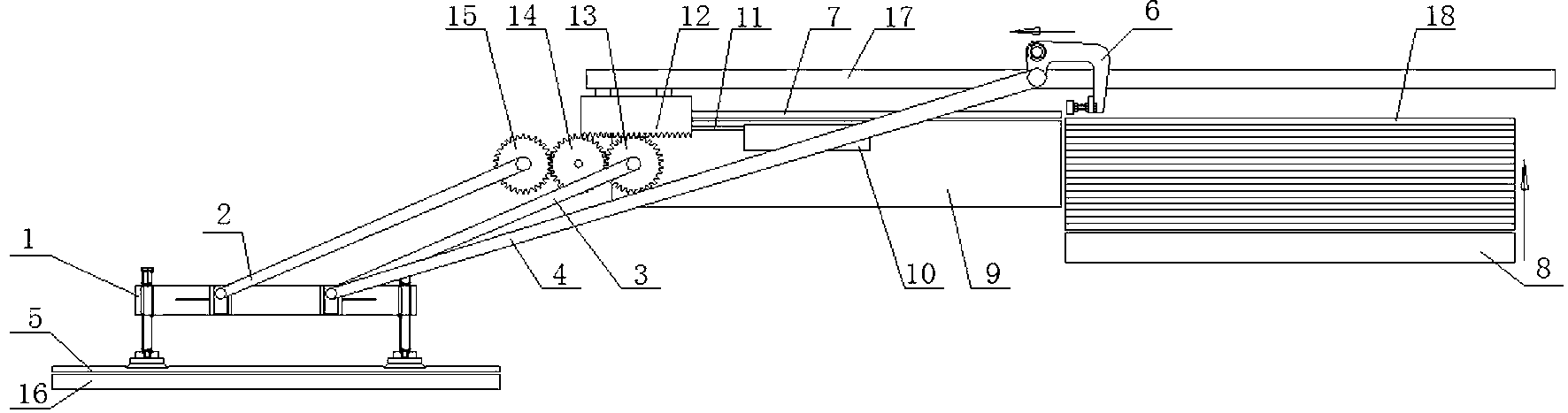

[0020] according to Figure 1~4 The specific structure of the present invention will be described in detail. Firstly, when it is used as a feeding device, the plate handling device includes parts such as a handling mechanism and a pushing mechanism. Wherein the conveying mechanism comprises the carrying rack 1 that is used for picking and placing the plate with suction cup at the bottom, the rack 9 that is used to place the plate to be transported with pulleys 17 on the side, the workbench 16 for placing the plate to be processed, It is a driving mechanism for driving the transport frame 1 to transport the plate between the material rack 9 and the workbench 16 . The driving mechanism includes the first gear 13, the second gear 14, and the third gear 15 meshed in sequence, and the reciprocating cylinder 10 (the driving mechanism uses the reciprocating cylinder as the power source, fully automatic feeding and discharging, greatly reducing The labor intensity of the work...

Embodiment 2

[0025]The reciprocating cylinder in Embodiment 1 is replaced by a drive motor, and the drive motor is arranged on the first gear 13 or the second gear 14 or the third gear 15 to drive the gear to rotate, to replace the reciprocating cylinder and the rack. Drive mode, and corresponding components such as reciprocating cylinder and rack are omitted, and the figure is omitted.

Embodiment 3

[0027] Such as Figure 5 As shown, one end of the third connecting rod 4 is hinged to the middle position of the second connecting rod 3, and other structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com