Semi-pull-lug easy-uncovering aluminum foil sealing film and preparing method thereof

A semi-tearing and sealing film technology, applied in chemical instruments and methods, sealing, closing, etc., can solve the problems of difficult storage, poor stability, and uneven sealing strength of the sealing film, so as to improve the heat sealing strength and heat sealing stability , uniform distribution, close contact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

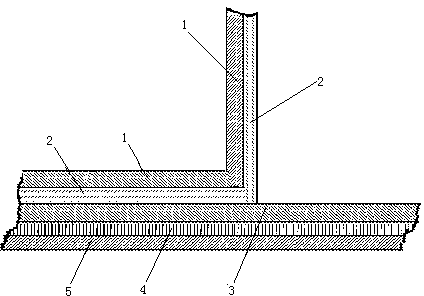

[0039] A semi-pull ear easy-to-peel aluminum foil sealing film, which is sequentially provided with a protective layer and an adhesive layer from top to bottom; the protective layer is composed of an integrally formed adhesive part and a free part, the adhesive part and the free part from above A first BOPET film layer 1 with a thickness of 20 μm and a PE film layer 2 with a thickness of 10 μm are sequentially arranged from the bottom; the bonding layer is sequentially provided with a second BOPET film layer 3 with a thickness of 12 μm and a thickness of The aluminum foil layer 4 with a thickness of 7 μm and the heat-seal layer 5 with a thickness of 10 μm; the PE film layer 2 in the bonding part and the second BOPET film layer 3 in the bonding layer are bonded into an integrated structure, the The free part constitutes a pull-ear structure; wherein the area of the bonding part accounts for 1 / 2 of the area of the aluminum foil sealing film, and the heat-sealing layer 5 is mad...

Embodiment 2

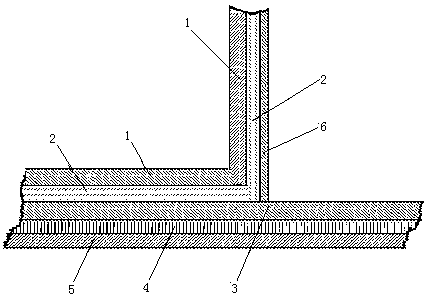

[0047] A semi-pull ear easy-to-peel aluminum foil sealing film, which is sequentially provided with a protective layer and an adhesive layer from top to bottom; the protective layer is composed of an integrally formed adhesive part and a free part, the adhesive part and the free part from above A first BOPET film layer 1 with a thickness of 30 μm and a PE film layer 2 with a thickness of 14 μm are arranged in order from the bottom; the bonding layer is successively provided with a second BOPET film layer 3 with a thickness of 14 μm and a thickness from top to bottom. An aluminum foil layer 4 with a thickness of 12 μm and a heat-seal layer 5 with a thickness of 20 μm; the PE film layer 2 in the bonding part and the second BOPET film layer 3 in the bonding layer are bonded into an integrated structure, the The free part constitutes a pull-ear structure; wherein the bonding part occupies 2 / 3 of the area of the entire aluminum foil sealing film, and the heat-sealing layer 5 is com...

Embodiment 3

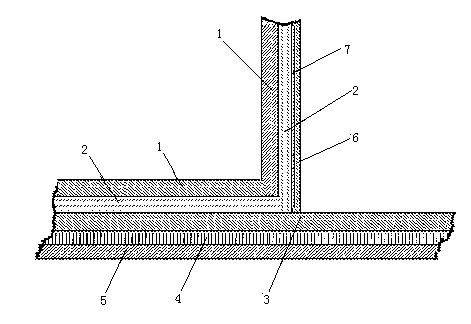

[0054] A semi-pull ear easy-to-peel aluminum foil sealing film, which is sequentially provided with a protective layer and an adhesive layer from top to bottom; the protective layer is composed of an integrally formed adhesive part and a free part, the adhesive part and the free part from above A first BOPET film layer 1 with a thickness of 35 μm and a PE film layer 2 with a thickness of 18 μm are arranged in order from the bottom; the bonding layer is successively provided with a second BOPET film layer 3 with a thickness of 15 μm and a thickness from top to bottom. The aluminum foil layer 4 with a thickness of 20 μm and the heat-seal layer 5 with a thickness of 30 μm; the PE film layer 2 in the bonding part and the second BOPET film layer 3 in the bonding layer are bonded into an integrated structure, the The free part constitutes a pull-tab structure, wherein the area of the bonding part accounts for 1 / 2 of the area of the aluminum foil sealing film, and the heat-sealing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com