Method and device for supplying zinc gas

A gas heating device and gas technology, applied in chemical instruments and methods, transportation and packaging, inorganic chemistry, etc., can solve problems such as the inability to produce zinc gas, achieve the effect of suppressing energy consumption and simple control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0112] Hereinafter, the present invention will be described more specifically by way of examples, but the scope of the present invention is not limited to these examples.

example 1

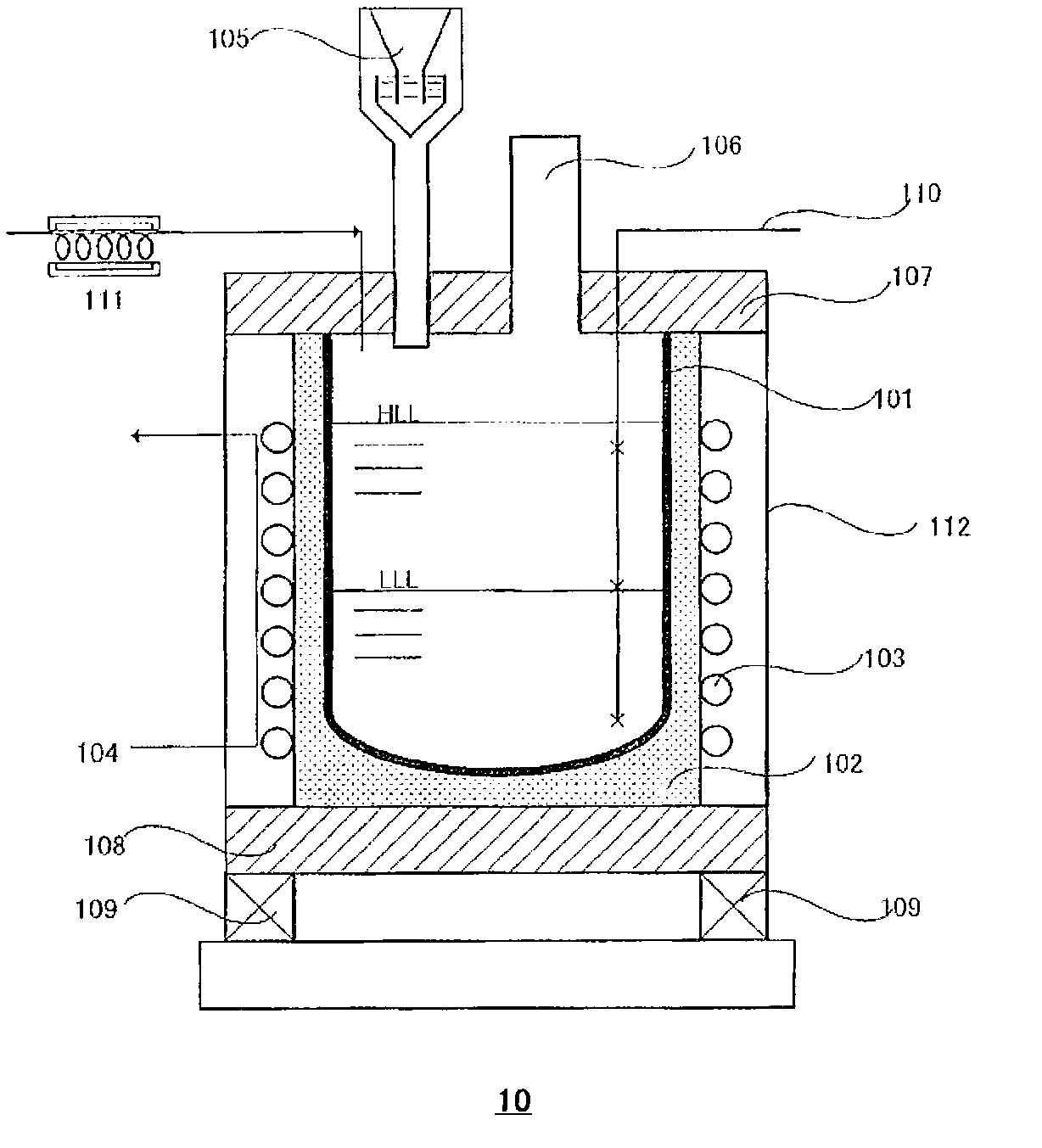

[0114] The zinc gas evaporator 10 used includes: an opaque quartz crucible 101 with an outer diameter of 460 mm, an inner diameter of 400 mm, a radius of curvature of 230 mm, and a height of 750 mm; and an induction coil 103 with a height of 500 mm and an inner diameter of 550 mm. The crucible 101 is placed on a bottom plate 108 made of silica-alumina low-cement castable material. The surrounding of the crucible 101 is insulated by silica sand, and a quartz evaporator cover 107 is installed, and the upper part is covered by a ceramic fiber board. And placed on the weighing device (floor scale) 109 . High-frequency induction heating uses a frequency of 500 Hz and a power supply with an output of 600 kW.

[0115] 330 kg of molten zinc at 450° C. was introduced into such a zinc gas evaporator 10 , and heated to the boiling point by high-frequency induction heating. The approximate formula for the relationship between the input power and the weight reduction rate (zinc evaporatio...

example 2

[0117] Using the same apparatus as in Example 1, the change in apparatus efficiency K when the liquid level of molten zinc was changed was determined. show the result in Figure 6 . The device efficiency K has almost no change when the liquid level of the molten zinc is above 50% of the liquid level. If the liquid level of the molten zinc is lower than 40% of the liquid level, a significant increase in the device efficiency K can be seen. reduce. If it is maintained at a range above 40% of the liquid level position of molten zinc, the change of device efficiency K is not obvious, and zinc gas can be generated by controlling the input power. In the range above 50% of the height position, induction heating can be performed with high precision.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com