Novel high-voltage gain mixing direct-current converter for photovoltaic grid-connected micro-inverter

A micro-inverter, hybrid DC technology, applied in photovoltaic power generation, DC power input into DC power output, output power conversion devices, etc., can solve the problem of high diode reverse blocking voltage, limited boost capacity, input problems such as large current ripple, to achieve the effect of reducing reverse blocking voltage stress, improving conversion efficiency, and simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

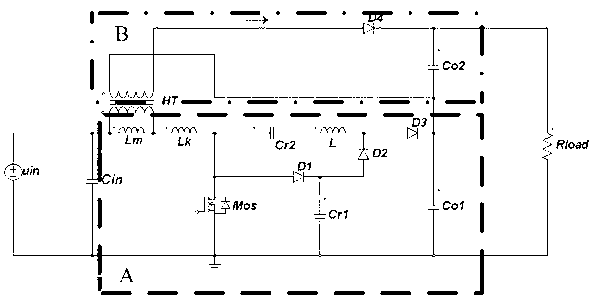

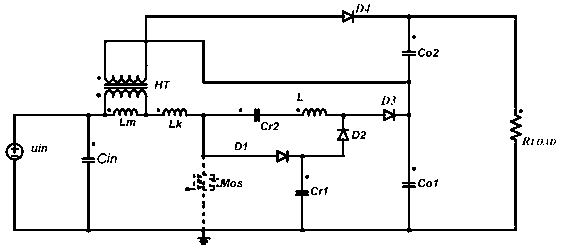

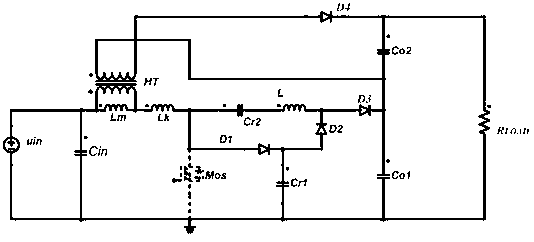

[0015] Such as figure 1 As shown, the present invention is composed of a novel Boost circuit (circuit A) with voltage doubling function and a flyback converter (circuit B). The Boost circuit and the flyback converter share an input terminal, which simplifies the circuit structure and can The leakage inductance of the transformer is fully utilized to improve the system efficiency; the output terminals of the two circuits are connected in series to increase the overall voltage gain of the converter. The doubling of the output voltage of the boost circuit reduces the turn ratio of the transformer in the flyback converter and reduces the reverse turn-off voltage stress of the output diode. The reduction of the turn ratio also reduces the leakage inductance energy and improves the system performance. efficiency. The capacitor in this circuit clamps the turn-off voltage of the main power device, reducing the voltage stress of the device.

[0016] The above DC-DC DC converter, as s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com