Vehicle power battery charging system and charging method

A technology for automotive power batteries and charging systems, applied in battery circuit devices, electric vehicles, current collectors, etc., can solve the damage of batteries and their control circuit contact wires and electronic components, system performance, durability, safety effects, Battery and line temperature rise and other problems, to achieve the effect of reducing loop current, equalizing charging, and reducing charging loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

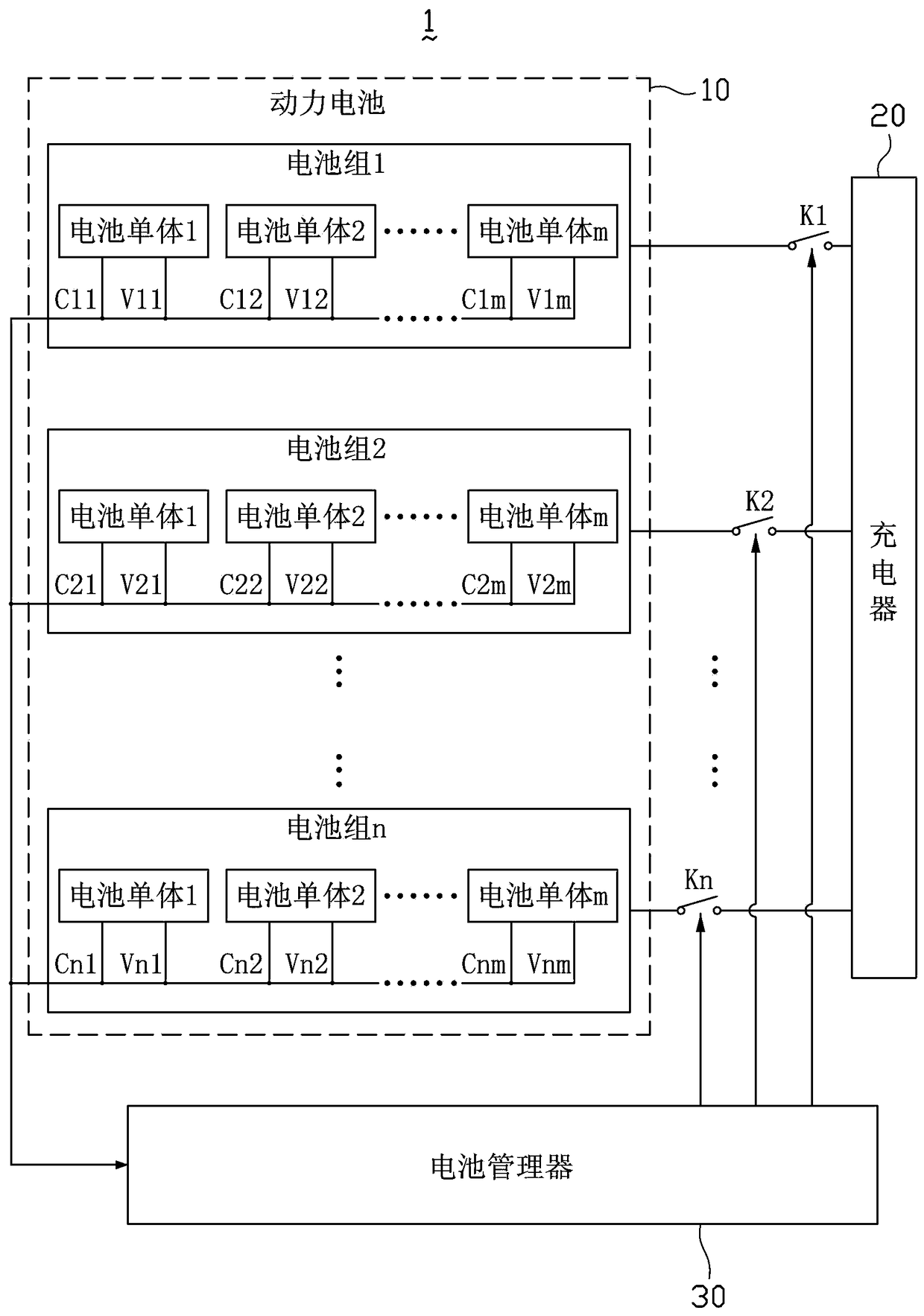

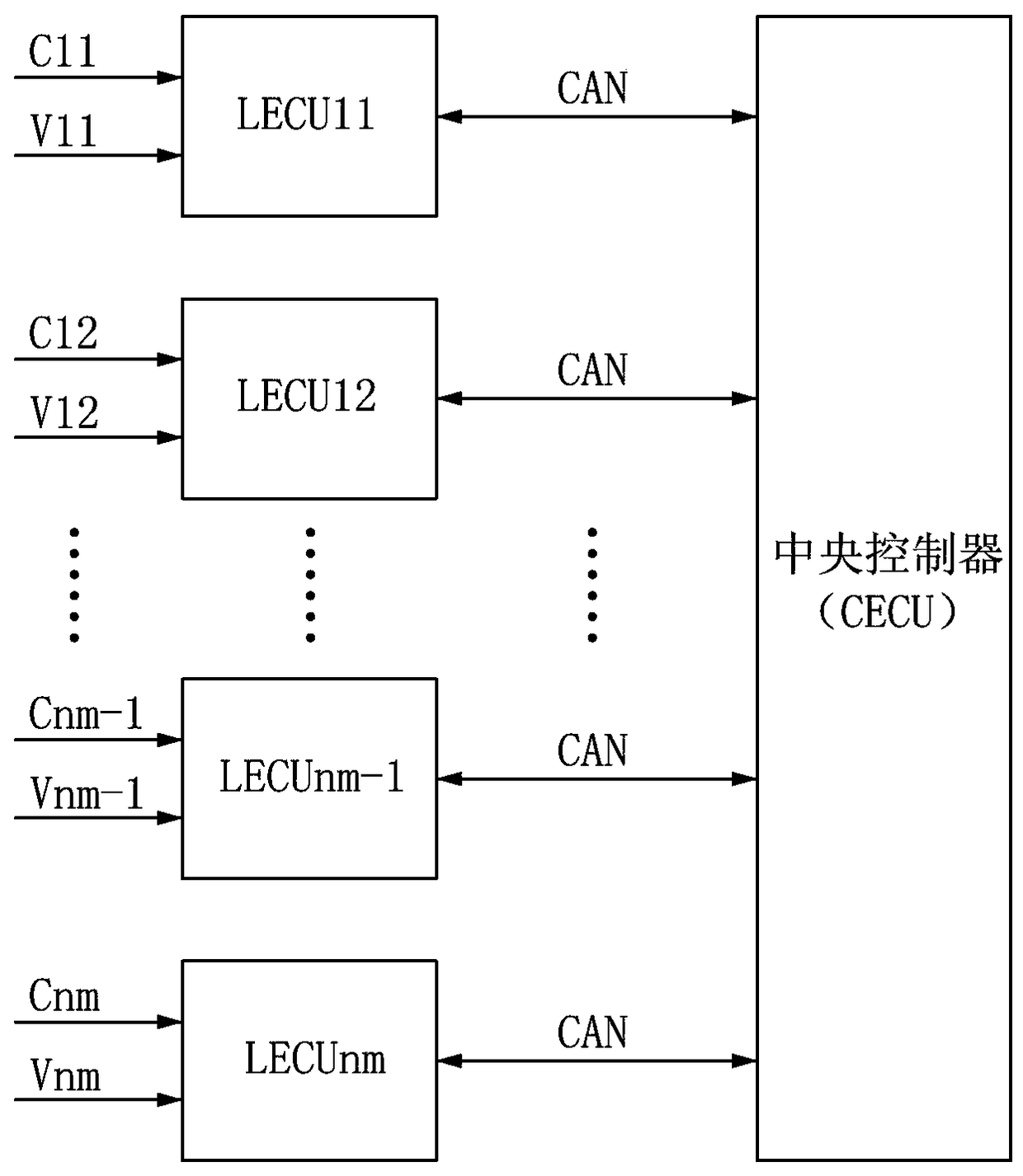

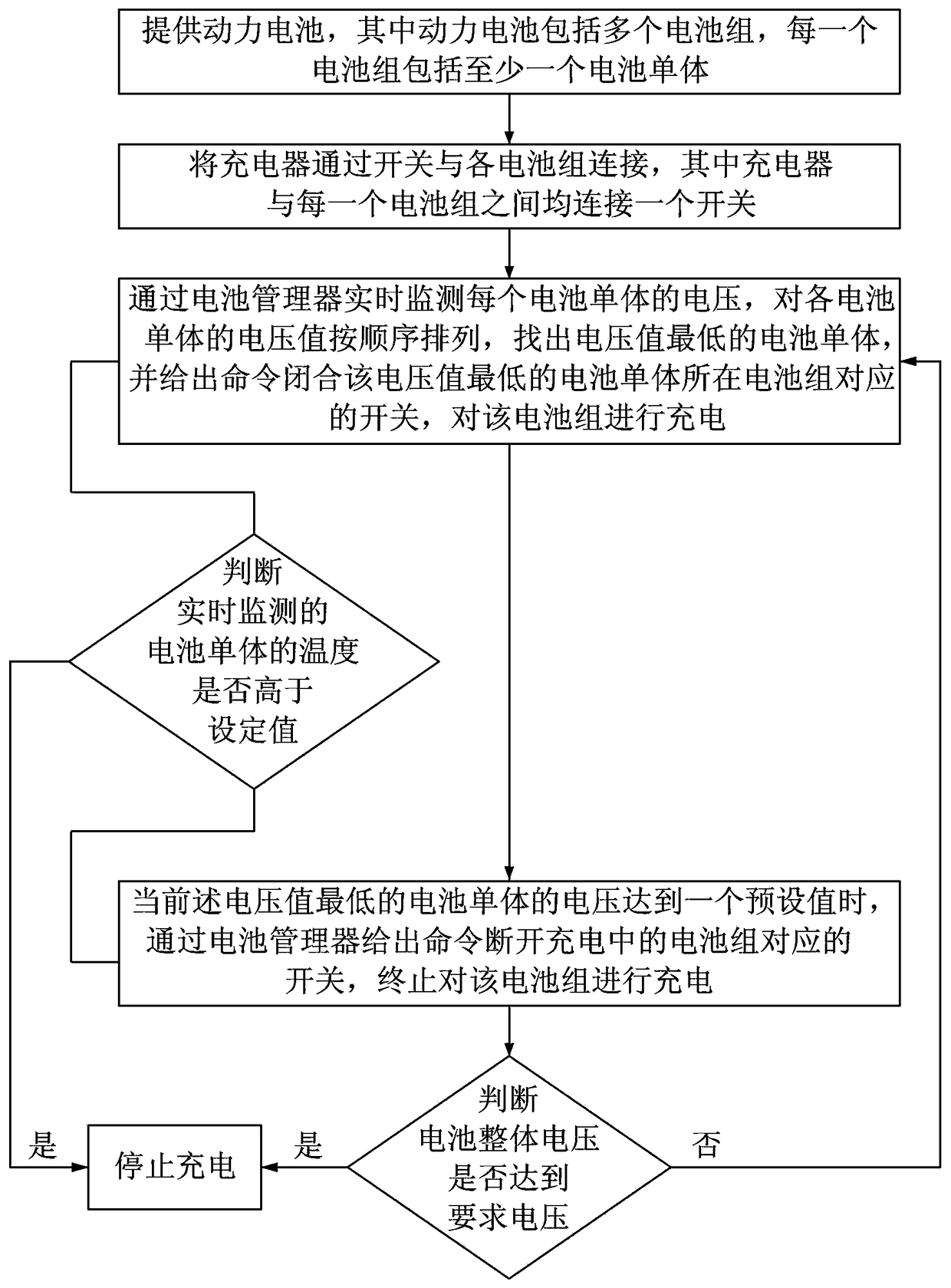

[0024] Please refer to figure 1 , the vehicle power battery charging system 1 of the preferred embodiment of the present invention includes a power battery 10, a charger 20, a battery manager 30 and a CAN network ( figure 2 ).

[0025] The power battery 10 includes multiple battery packs connected in parallel, represented by battery packs 1 to n in the figure, wherein n is a natural number greater than 1. Each battery pack further includes one or more battery cells, represented by battery cells 1 to m in the figure, wherein m is a natural number greater than 1. It should be noted that there is no limitation on the connection mode of the multiple battery cells in the battery pack, which can be connected in series, parallel or a combination thereof, and the connection mode of the battery cells in each battery pack can also be different. In addition, the number of battery cells in each battery pack can also be different, and the battery pack can also include only one battery c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com