Ultrasonic pipe wall thickness measuring device

An ultrasonic wave and tube wall technology, applied in the field of ultrasonic waves, can solve problems such as ultrasonic wave velocity scattering, detection sensitivity drop, and speed instability, and achieve the effects of reducing rotational resistance, increasing surface cleanliness, and compact device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

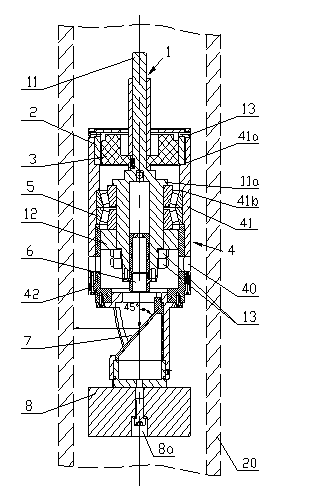

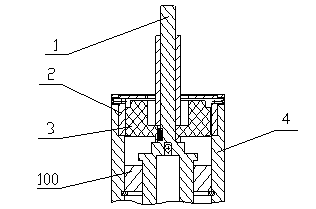

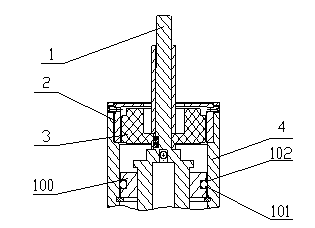

[0026] control figure 1 , the ultrasonic tube wall thickness measuring device of the present invention is placed in the pipeline to be tested, and is mainly composed of an ultrasonic probe 6, a mirror 7, a fixed shaft 1, a stator 3, a rotor 2 and a rotor housing 4, and the fixed shaft 1 is placed inside the rotor housing. At the center, the stator 3 is concentrically connected to the fixed shaft, the rotor 2 is concentrically connected to the inner wall of the rotor housing 4, the ultrasonic probe 6 is connected to the fixed shaft 1, and the mirror 7 is connected to the rotor housing 4, and is arranged such that The reflection mirror surface forms an acute angle with the propagation direction of the ultrasonic wave.

[0027] In the above solution, the rotor 2 is a magnetic steel connected to the inner wall of the rotor casing, and the stator 3 is a coil winding. In order to make the reflection of the ultrasonic wave emitted by the ultrasonic probe 6 by the reflective mirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com