Pipe pile leading-hole construction method under boulder cluster geological condition

A technology of geological conditions and construction methods, applied in drilling equipment and methods, earthwork drilling, drilling equipment, etc., can solve problems such as inability to penetrate rocks, increased construction costs, rapid wear of drilling tools, etc., and achieve a wide range of strata applications. , Flexible drilling ability, the effect of preventing buried drilling phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

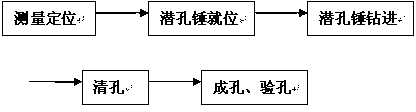

[0010] see figure 1 , the pipe pile lead hole construction method under the geological conditions of the boulder group described in the present embodiment is carried out according to the following steps:

[0011] ⑴Measurement positioning:

[0012] Based on the coordinate measurement control point set by the owner in the field area as the benchmark, the center pile of each group of piles and the piles of any pile coaxial with the center pile are released one by one through coordinate conversion, rotation angle, distance measurement, and fixed point by using the range finder. The other pile positions of each group of piles are released one by one with a steel tape using the released ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com