Steel bar connection method and matched fastener thereof

A connection method and steel bar technology are applied in the fields of steel bar connection fasteners, building components, and steel bar connections, which can solve the problems of difficult quality assurance and construction difficulties, improve loading and unloading speed and connection reliability, reduce labor intensity of workers, and facilitate construction. management effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The present invention mainly comprises following processing steps:

[0022] 1. Straighten the steel bars;

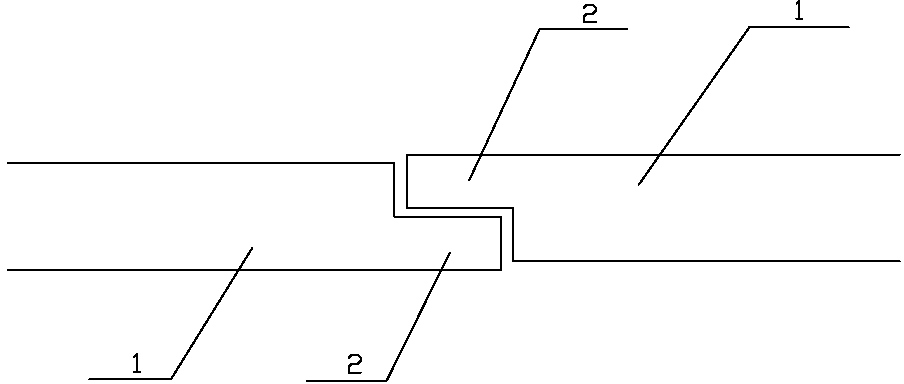

[0023] 2. Cut out the tenon at the end of the steel bar: such as figure 1 As shown, the end of the steel bar 1 is first cut from the middle along the axial direction of the steel bar, with a length of 100 mm, and then half of the cut is removed to form the tenon 2;

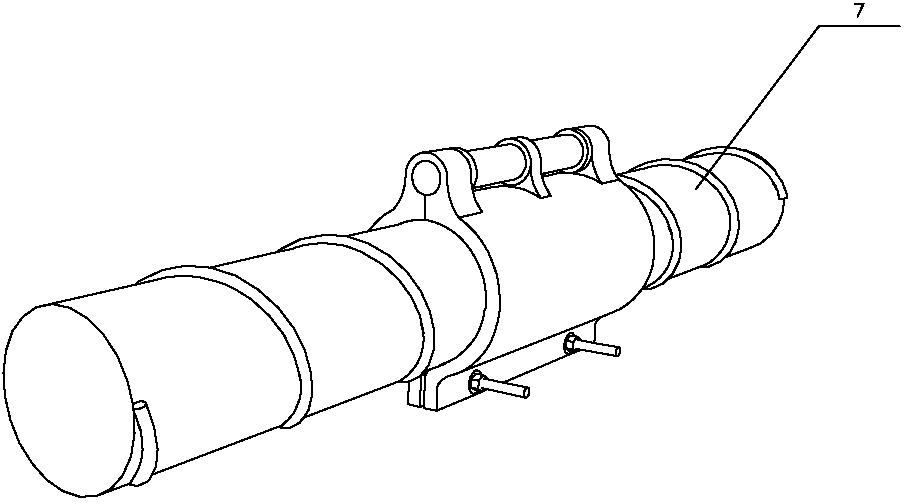

[0024] 3. Butt the tenons of the two steel bars, use the matching fasteners to fit the butt joints of the steel bars, and tighten the bolts on the fasteners.

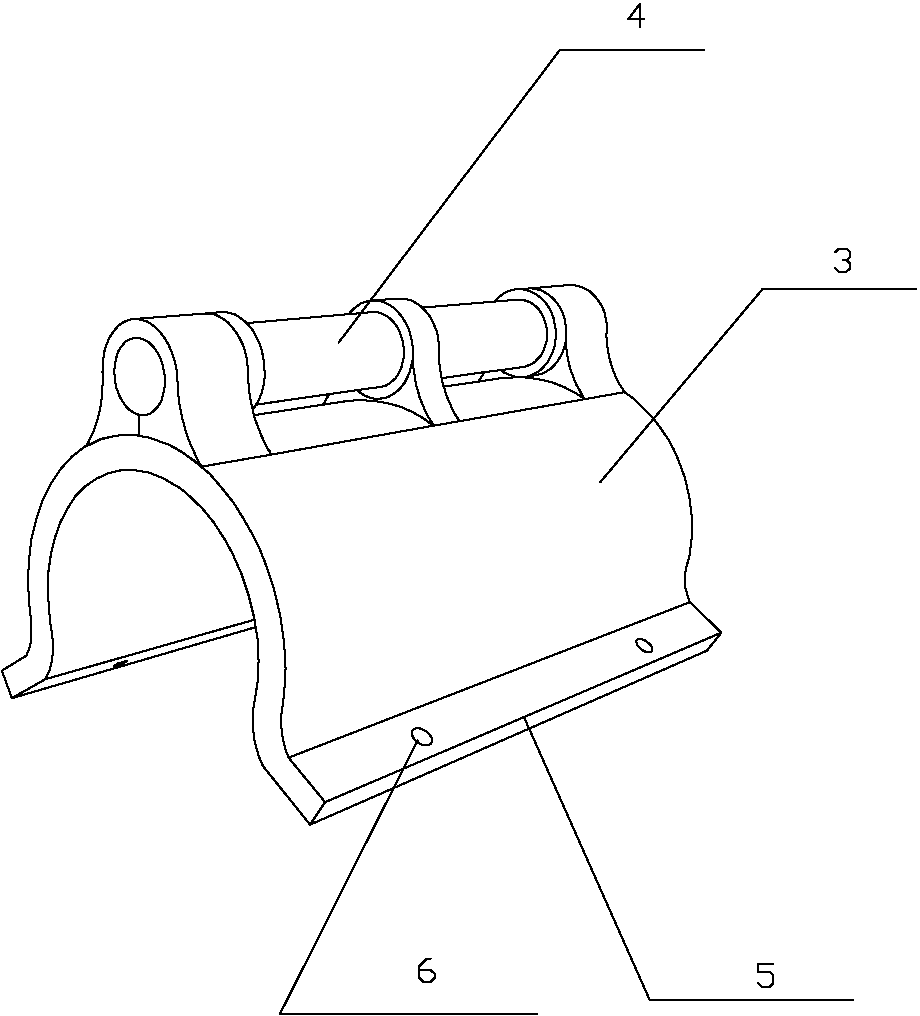

[0025] The present invention also provides a fastener that can be used in conjunction with the above method. Such as figure 2 As shown, the fastener is composed of two symmetrical steel semi-cylindrical bodies 3 . One side of the two bodies is connected together by a hinge 4 , and flanges 5 are provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com