Method for promoting anaerobic fermentation of surplus sludge to produce acid by using biosurfactant

A technology of excess sludge and anaerobic fermentation, applied in the field of solid waste recycling, can solve the problems of non-biodegradation, toxicity of chemical surfactants, etc., to promote dissolution, increase acid production, good ecological safety and compatibility Soluble effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

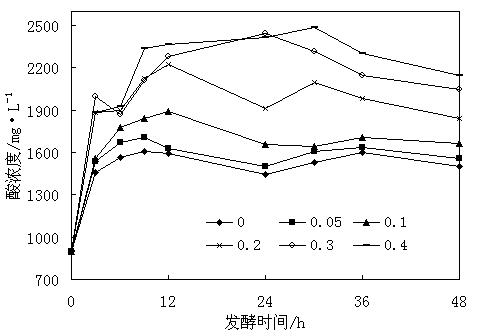

[0022] In order to determine the optimal conditions for biosurfactant alkyl polyglycosides to promote sludge hydrolysis and acid production, the effects of different dosage and fermentation time on sludge hydrolysis and acid production were discussed.

[0023] (1) Add 100mL of excess sludge to 6 reaction bottles respectively. The total suspended solid concentration of the excess sludge is 28700mg / L, the volatile solid concentration is 11400mg / L, and different amounts are added to bottles 2-6 ( 0.05, 0.1, 0.2, 0.3, 0.4g / gTSS) of alkyl polyglycosides, and bottle No. 1 was set as a blank control group (without adding alkyl polyglycosides).

[0024] (2) After deoxygenating and nitrogenizing the reaction bottle for 10 minutes, seal the reaction bottle, put it in a constant temperature shaking incubator at 30°C for anaerobic fermentation, and complete the biosurfactant alkyl polyglycosides after 48 hours to promote the anaerobic fermentation of the remaining sludge The process of fe...

Embodiment 2

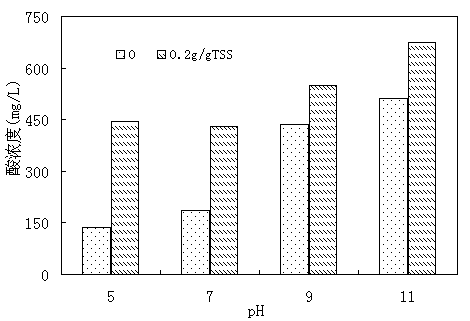

[0026] In order to determine the optimal conditions for biosurfactant alkyl polyglycosides to promote sludge hydrolysis and acid production, the effects of different pH on sludge hydrolysis and acid production were discussed.

[0027] (1) Add 100mL of excess sludge to 8 reaction bottles respectively. The total suspended solid concentration of the excess sludge is 24000mg / L, the volatile solid concentration is 10200mg / L, and the pH values of bottles 1-4 are adjusted to 5 and 7 respectively. , 9 and 11, add 0.2g / gTSS of alkyl polyglycoside, 5-8 is the control group (that is, adjust the pH value to 5, 7, 9 and 11 respectively but do not add alkyl polyglycoside).

[0028] (2) After deoxygenating and nitrogenizing the reaction bottle for 10 minutes, seal the reaction bottle and put it into a constant temperature shaking incubator at 30°C for anaerobic fermentation. The process of oxygen fermentation to produce acid. Depend on figure 2 It can be seen that within the experimenta...

Embodiment 3

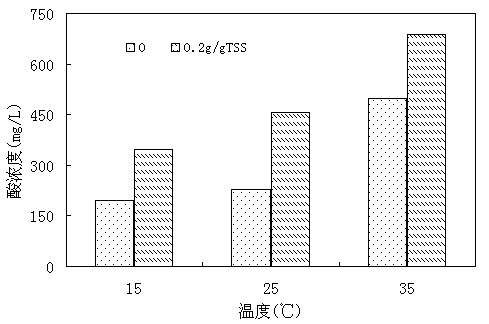

[0030] In order to determine the optimal conditions for biosurfactant alkyl polyglycosides to promote sludge hydrolysis and acid production, the effects of different temperatures on sludge hydrolysis and acid production were discussed.

[0031] (1) Add 100mL of excess sludge to 6 reaction bottles respectively. The total suspended solid concentration of the excess sludge is 24000mg / L, the volatile solid concentration is 10200mg / L, and the pH value is adjusted to 9. Dosing in bottles 1-3 Alkyl polyglycoside 0.2g / gTSS, 4-6 is the control group, without adding alkyl polyglycoside.

[0032] (2) After deoxygenating and nitrogenizing the reaction bottle for 10 minutes, seal the reaction bottle and place it in a constant temperature shaking incubator respectively. No. 1 and No. 4 were anaerobically fermented at 15°C, and No. 2 and No. 5 were anaerobically fermented at 25°C. , No. 3 and No. 6 were anaerobically fermented at 35°C, and after 12 hours, the biosurfactant alkyl polyglycosid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com