Production method and combination material formula of environment-friendly high-strength reclaimed butyl rubber

A production method and an environment-friendly technology are applied in the production of environment-friendly high-strength butyl reclaimed rubber and the formulation of its combined materials, which can solve the problems of insufficient desulfurization, product environmental protection indicators failing to meet environmental protection requirements, and high Mooney viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

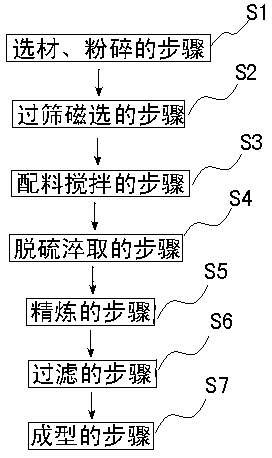

Method used

Image

Examples

Embodiment 1

[0046] Select 100 parts of high-quality waste butyl inner tubes with a strength above 9MPa, crush them into flakes, select at least a 2-4 mesh screen to sieve, and then use a magnetic separator to remove the iron wire from the sieved rubber powder. Add 2 parts of environmentally friendly rubber softener and 2 parts of reinforcing agent to the above-mentioned rubber powder that has been sieved and magnetically separated. In this embodiment, the environmentally friendly rubber softener is selected as paraffin oil, and the selected reinforcing agent is Composed of high-reinforcing carbon black. Then stir to form a combined material; use high temperature and atmospheric pressure desulfurization and oil extraction for the above-mentioned combined material after stirring, and the high temperature is controlled at 400°C; then it is refined on a refiner, and the number of passes is one roll; Then filter in the filter, using filter mesh at least 60 mesh; finally shape.

Embodiment 2

[0048] Select 100 parts of high-quality waste butyl inner tubes with a strength above 9MPa, crush them into flakes, select at least a 2-4 mesh screen to sieve, and then use a magnetic separator to remove the iron wire from the sieved rubber powder. Add 5 parts of environmentally friendly rubber softener and 1 part of reinforcing agent to the above-mentioned rubber powder that has been sieved and magnetically separated. In this embodiment, the environmentally friendly rubber softener is selected to be composed of naphthenic oil, and the selected reinforcing agent is Made of highly reinforced resin. Then it is stirred to form a combined material; the above-mentioned combined material after stirring is subjected to high temperature and normal pressure desulfurization and oil quenching, and the high temperature is controlled at 230°C; then it is refined on a refiner, and the number of passes is twice. ; Then filter in a filter, using a filter mesh of 60 mesh; finally shape.

Embodiment 3

[0050] Select 100 parts of high-quality waste butyl inner tubes with a strength above 9MPa, crush them into flakes, select at least a 2-4 mesh screen to sieve, and then use a magnetic separator to remove the iron wire from the sieved rubber powder. Add 4 parts of environmentally friendly rubber softener and 1.5 parts of reinforcing agent to the above-mentioned rubber powder that has been sieved and magnetically separated. In this example, the selected environmentally friendly rubber softener is composed of naphthenic oil, and the selected reinforcing The agent is composed of highly reinforcing carbon black. Then stir to form a combined material; use high temperature and normal pressure desulfurization and oil extraction for the above-mentioned combined material after stirring, and the high temperature is controlled at 310°C; then it is refined on a refiner, and the number of passes is once; Then filter in a filter, using a filter mesh of 70 mesh; finally shape.

[0051] In the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com