Preparation method of waterborne polyurethane containing fluorescent dye

A technology of water-based polyurethane and fluorescent dye, applied in the field of fluorescent water-based polyurethane, can solve the problems of limited dispersion and uneconomical artificial synthesis of fluorescent powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

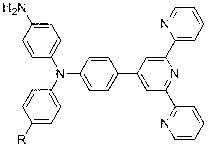

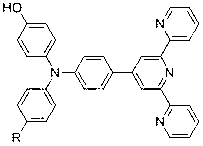

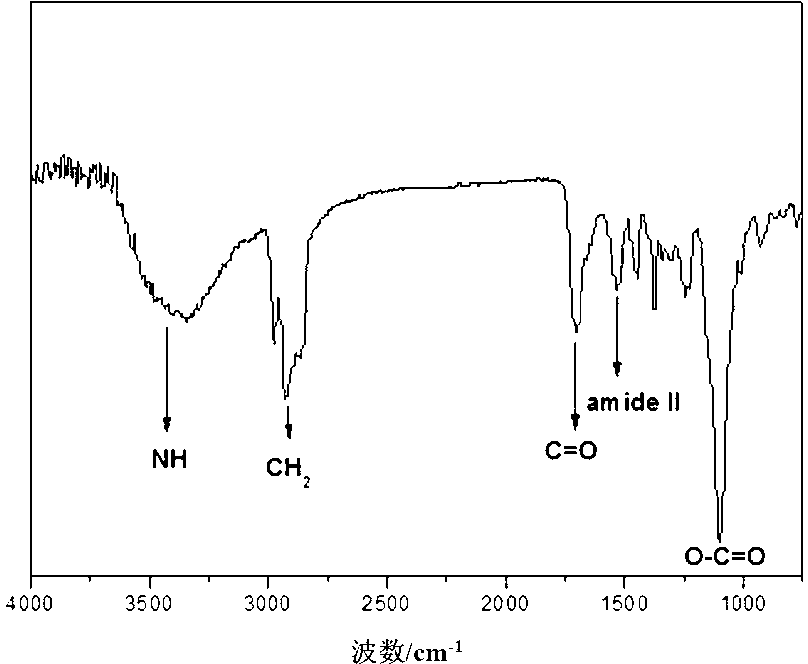

[0039] Example 1: Dissolve 17 mg of hydroxyl-containing fluorescent dye A in 5 g of N,N-dimethylformamide to obtain a solution of fluorescent dye A in N,N-dimethylformamide. in N 2 Under the protection of 110°C vacuum dehydration for 2 hours, 40g of polyoxypropylene triol, 13.76g of 4,4'-dicyclohexylmethane diisocyanate (HMDI) and N,N-dimethylformamide of fluorescent dye A The solution was placed in a 250ml three-neck flask and reacted at 80°C for 2 hours, then added 2.18g of dimethylolpropionic acid and 1.26g of 1,4-butanediol, added 0.06g of dibutyltin dilaurate, and 0.06g of stannous octoate g, 60g of acetone, reacted at 60°C for 6 hours, cooled to 20°C and discharged to obtain a fluorescent water-based polyurethane prepolymer; pour the prepolymer into an emulsification tank, and add triethylamine at a speed of 3000r / min 2.26g was neutralized, and 150g of water was added, and emulsified to obtain light yellow-green translucent fluorescent water-based polyurethane emulsi...

Embodiment 2

[0043] Example 2: Dissolve 622 mg of hydroxyl-containing fluorescent dye A with 30 g of N-methylpyrrolidone to obtain a solution of fluorescent dye A in N-methylpyrrolidone. in N 2 40g of polyethylene adipate diol, 13.76g of 4,4'-dicyclohexylmethane diisocyanate (HMDI), 13.76g of hexamethylene diisocyanate (HDI ) 5g and N-methylpyrrolidone solution of fluorescent dye A were placed in a 250ml three-necked flask, reacted at 90°C for 2 hours, then added dimethylol propionic acid 2.18g and ethylene glycol 1.26g, added dilauric acid di 0.06 g of butyltin, 0.06 g of stannous octoate, and 60 g of acetone were reacted at 60° C. for 6 hours. Cool down to 20°C and discharge to obtain a fluorescent water-based polyurethane prepolymer; pour the prepolymer into an emulsification tank, add 2.26 g of triethylamine to neutralize it at a speed of 3000 r / min, add 245 g of water to emulsify, and obtain a yellow-green color Translucent fluorescent water-based polyurethane emulsion.

Embodiment 3

[0044] Example 3: Dissolve 7 mg of hydroxyl-containing fluorescent dye A in 5 g of N,N-dimethylacetamide to obtain a solution of fluorescent dye A in N,N-dimethylacetamide. in N 2 Under the protection of 110°C vacuum dehydration for 2 hours, 30g of polyoxypropylene diol, 30.45g of toluene diisocyanate (TDI) and N,N-dimethylacetamide solution of fluorescent dye A were placed in a 250ml three-necked flask , react at 80°C for 2 hours, then add 5.59g of dihydroxy half ester and 1.26g of diethylene glycol, add 0.5g of 1,4-butanediol, add 0.06g of dibutyltin dilaurate, 0.06g of stannous octoate g, 60g of acetone, react at 60°C for 6 hours and then cool down to 20°C to obtain a fluorescent water-based polyurethane prepolymer; pour the prepolymer into an emulsification tank, and add 2.7g of triethylamine at a speed of 3000r / min Neutralize, add 225g of water for emulsification, and obtain light yellow-green translucent fluorescent water-based polyurethane emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com