Method for treating waste water by using cyclic regeneration porous hollow aluminum oxide nano fiber

A hollow alumina and nanofiber technology is applied in the field of porous hollow alumina nanofiber treatment of wastewater, which can solve the problems affecting the adsorption efficiency of alumina on water pollutants and the low specific surface area of alumina, and achieve high sewage treatment capacity and high efficiency. Specific surface area, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

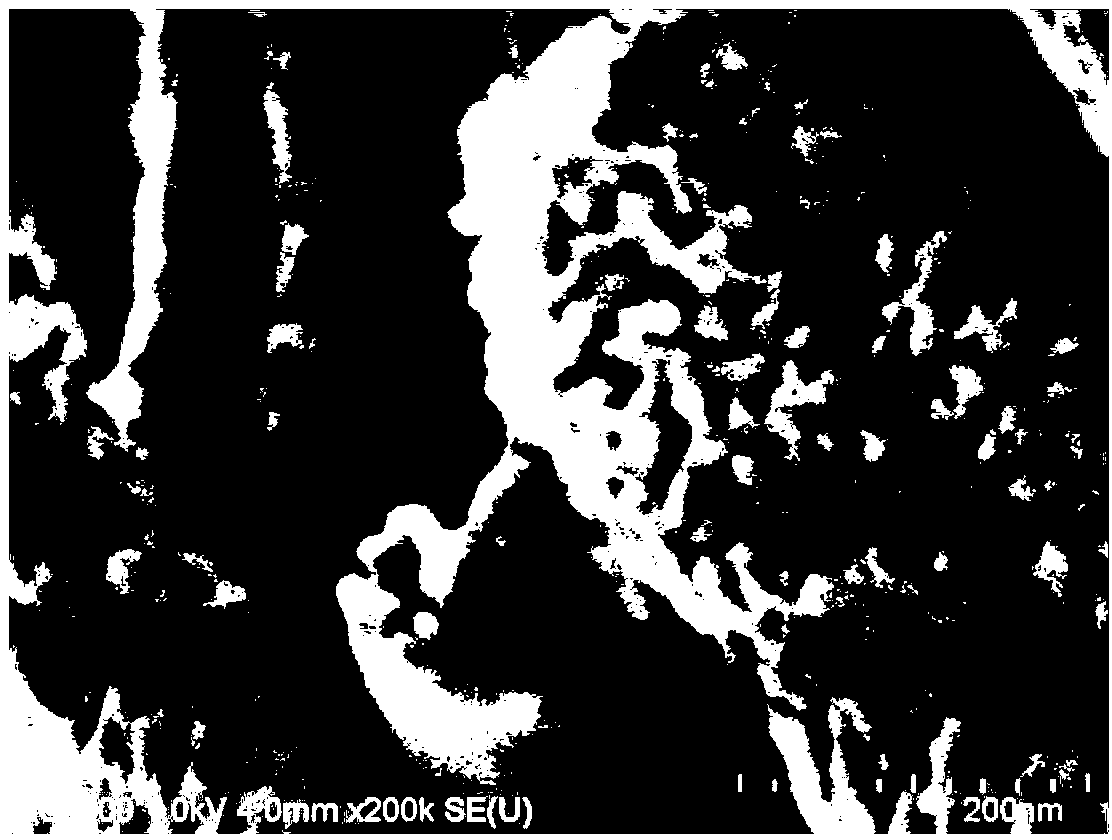

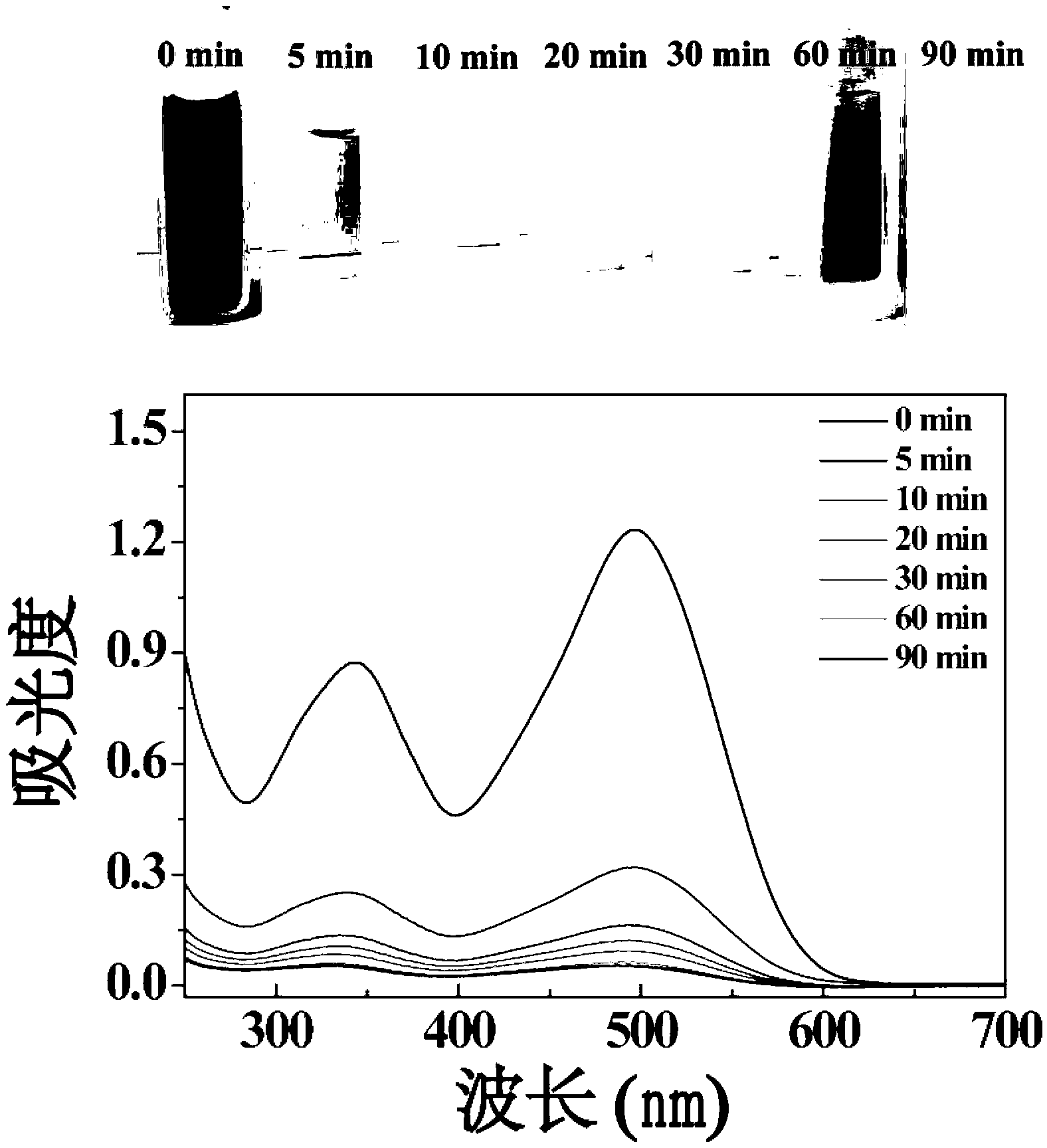

[0026] Porous hollow alumina nanofibers were prepared by electrospinning with an average diameter of 450 nm and a specific surface area of 48 m 2 / g, 0.01g of nanofibers were dispersed in 15g of methylene blue aqueous solution (100mg / L), stirred and adsorbed for 2h, and analyzed by ultraviolet spectroscopy, the removal rate of methylene blue in the solution was 91.3%. The dye-adsorbed nanofibers were calcined at 500 °C for 2 h, and then placed in the same concentration of dye solution for the second and third adsorption. The removal rates of dye in the solution were 89.7% and 88%, respectively.

Embodiment 2

[0028] Porous hollow alumina nanofibers were prepared by electrospinning with an average diameter of 280 nm and a specific surface area of 61 m 2 / g, disperse 0.02g of nanofibers in 15g of Congo red aqueous solution (50mg / L), stir and absorb for 2h, and the removal rate of Congo red in the solution is 97.7% by ultraviolet spectrum analysis. The dye-adsorbed nanofibers were calcined at 700°C for 4 hours, and then placed in the same concentration of dye solution for the second and third adsorption. The removal rates of dye in the solution were 94.7% and 92%, respectively.

Embodiment 3

[0030] Porous hollow alumina nanofibers were prepared by electrospinning with an average diameter of 790 nm and a specific surface area of 44 m 2 / g, disperse 0.03g of nanofibers in 15g of methyl orange aqueous solution (100mg / L), stir and adsorb for 2h, and the removal rate of Congo red is 92% by ultraviolet spectrum analysis. The dye-adsorbed nanofibers were calcined at 600°C for 4 hours, and the dye molecules were removed and placed in the same concentration of dye solution for the second and third adsorption. The removal rates of dye in the solution were 88.7% and 86% respectively. %.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com