Low-rail large-dip-angle reciprocating feeder

A large-inclination, reciprocating technology, applied in the direction of transportation, packaging, loading/unloading, etc., can solve the problems of low production efficiency, wear of rotating parts, high power consumption of feeders, etc., achieve small size, reduce frictional resistance, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

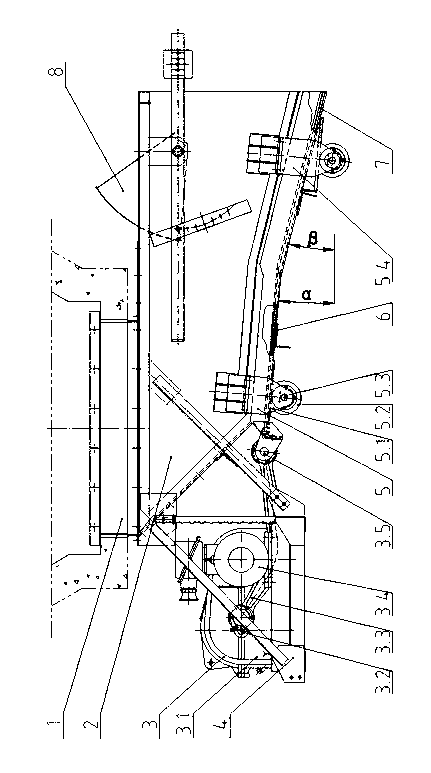

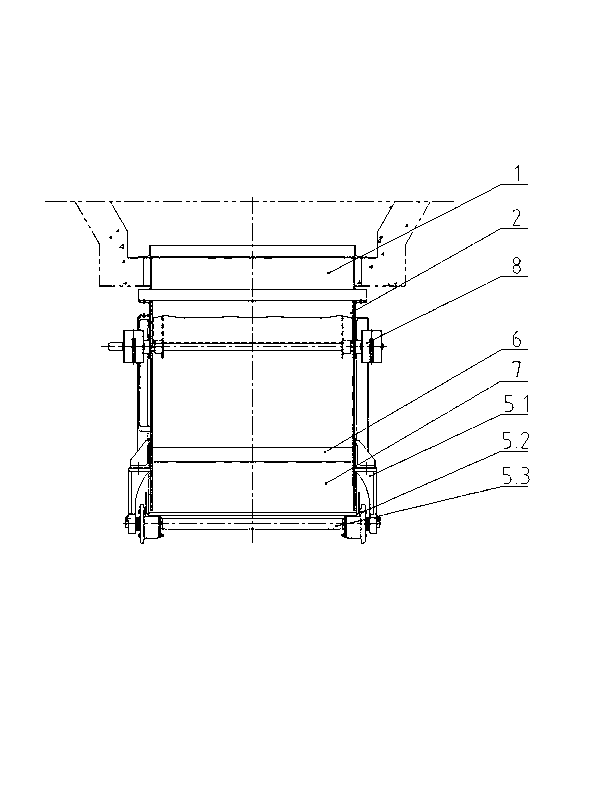

[0018] control Figure 1~2 , The present invention's low-rail high-inclination reciprocating feeder is composed of a funnel 1, a tank body 2, a driving device 3, a support roller 5, a small-inclination base plate 6, a large-inclination angle base plate 7 and a gate device 8. The upper part of the funnel 1 is connected with the silo mouth, the lower part is connected with the upper part of the tank body 2, the bottom frame 4 is provided with a reducer 3.1 and a motor 3.4, and the motor 3.4 is connected with the high-speed shaft of the reducer 3.1 through a coupling, One end of the connecting rod 3.3 is connected to the output shaft of the reducer 3.1 through the crank 3.2, and the other end is connected to the small-inclination bottom plate 6 through the pin shaft 3.5, and the small-inclination bottom plate 6 and the large-inclination bottom plate 7 are welded at the joint section. 4 is welded with the tank body 2, and a set of support wheels 5 are respectively provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com