Tire repair fixer

A fixer and tire repair technology, which is applied in the field of bicycle maintenance tools, can solve the problems of many conditions, laboriousness, and inability to guarantee the quality of sticking, and achieve the effect of uniform sticking, increasing the contact area, and increasing the connection friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

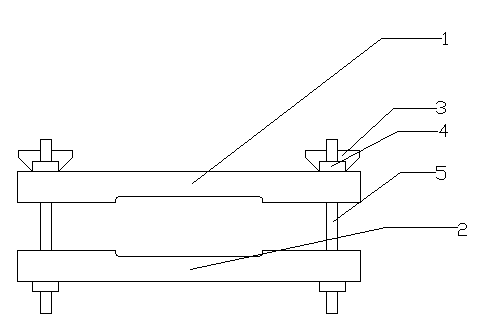

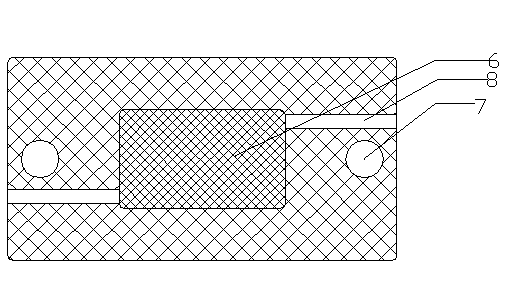

[0017] like figure 1 , figure 2 As shown, the tire patch fixer includes an upper splint 1, a lower splint 2, two fixing screws 5, and four fixing nuts 4. The edges of the upper splint 1 and the lower splint 2 are symmetrically provided with two through holes 7, and the two fixing screws 5 passes through the two through holes 7 of the upper splint 1 and the lower splint 2 in turn, and the four fixing nuts 4 are sequentially arranged at the two ends of the two screw rods 5, and the center positions of the two facing surfaces of the upper splint 1 and the lower splint 2 are respectively Two inner concave surfaces 6 are processed, and the two facing surfaces of the upper splint and the lower splint are evenly distributed with granular protrusions, and the density of the granular protrusions on the inner concave surface 6 is greater than that of the rest of the upper splint 1 or the lower splint 2; Four fixed nuts 4 fixed on the two fixed rods, two of which are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com