Industrial robot for welding

An industrial robot and encoder technology, which is applied in welding equipment, plasma welding equipment, gas flame welding equipment, etc., can solve the problems of inconvenient welding and cutting for a single robot, difficulty in adapting to demand, high maintenance cost, etc., and achieve product conception Novelty, ingenious design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

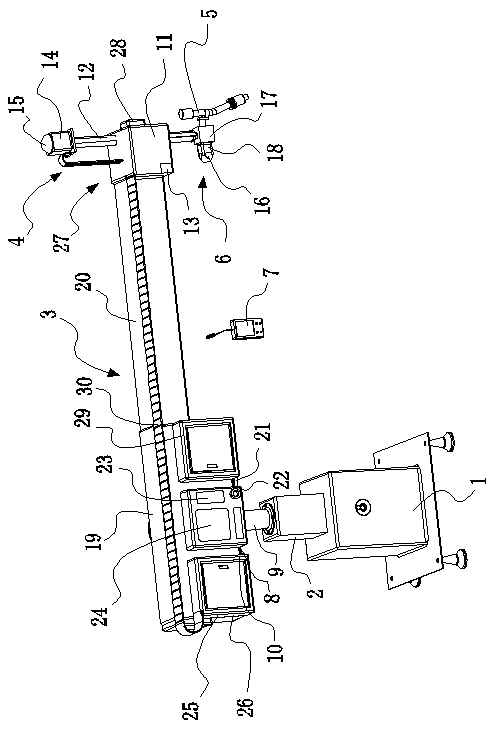

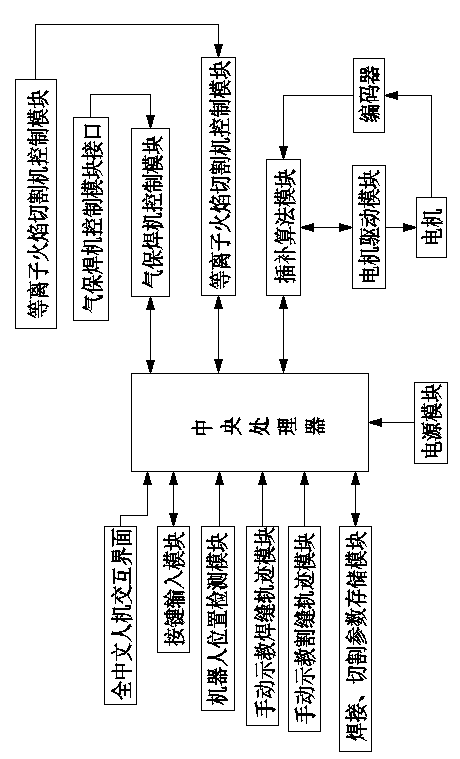

[0020] Such as figure 1 , 2 As shown, an industrial robot for welding includes a fixed frame 1, a lifting base 2 is arranged on the fixed frame 1, and a horizontal support arm 3 that can rotate horizontally around the axis of the lifting base 2 is arranged on the lifting base 2, On the horizontal support arm 3, there is a longitudinal movement rotation mechanism 4 which can move along the direction perpendicular to the axis of the horizontal support arm 3, and a longitudinal rotation mechanism 6 with welding torch and cutting torch holder 5 arranged on the longitudinal movement rotation mechanism 4 , the horizontal support arm 3 is provided with an electronic control system for controlling the movement of the horizontal support arm 3, the vertical movement rotation mechanism 4 and the vertical rotation mechanism 6, and a signal connection with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com