Edge-brushing device for pole plate edge-brushing machine

An edge brushing machine and edge brushing technology are applied to machine tools, grinders, metal processing equipment and other directions suitable for grinding the edge of workpieces, which can solve the problems of low production efficiency, large workload, pollution of workshop and surrounding environment, etc. The effect of brushing edge, improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

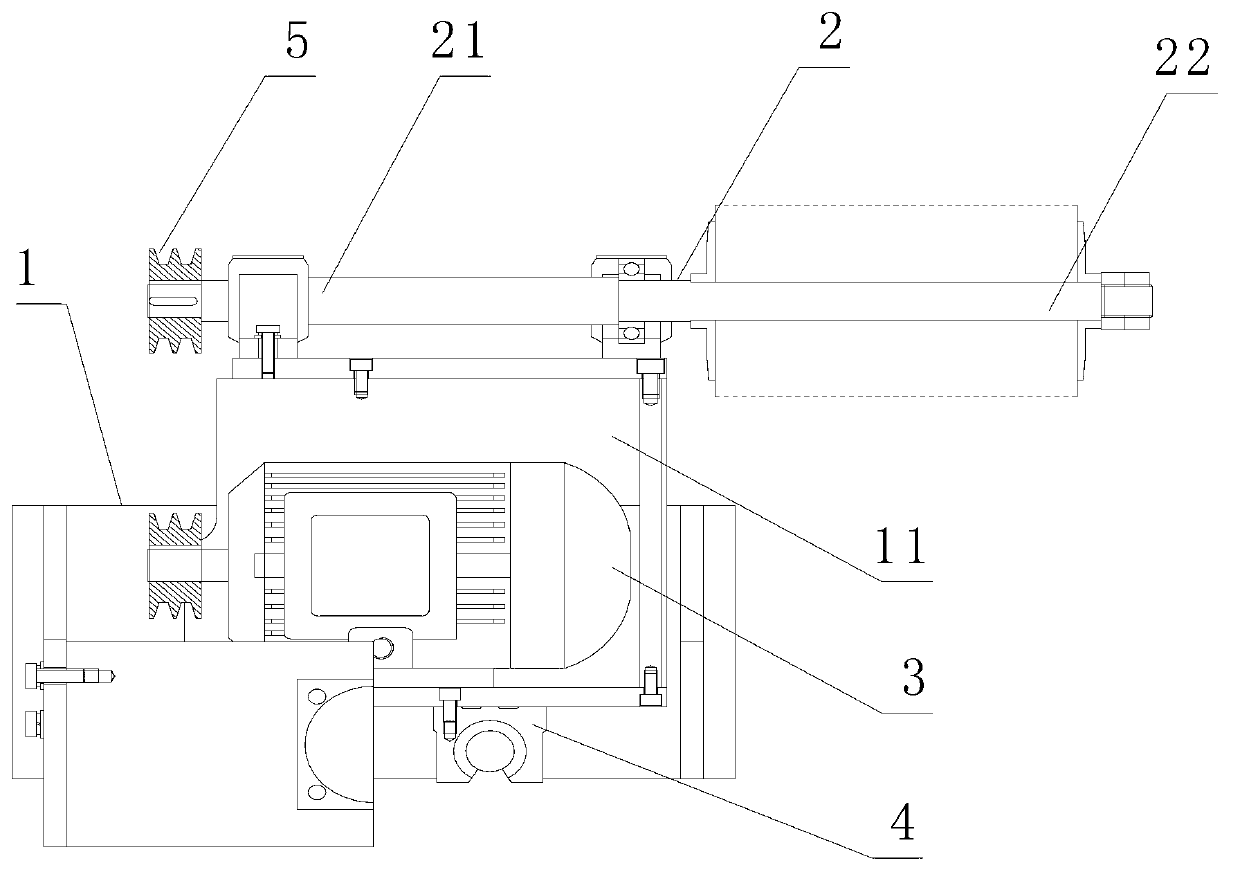

[0014] Such as figure 1 As shown, a brushing device of a pole plate edge brushing machine includes a frame 1 and a movable seat 11 movably connected to the frame 1, and the movable seat 11 is fixed with a brush edge assembly 2 and a device for controlling the operation of the brush edge assembly 2. A power device 3, the frame 1 is provided with a driving device 4 for driving the movable seat 11 to reciprocate along the center line of the frame 1, the brush edge assembly 2 includes a rotating shaft 21, a brush edge portion 22 installed at the right end of the rotating shaft 21, The left end of the rotating shaft 21 is connected to the power device 3, which is convenient for installation and has good reliability. The driving device 4 drives the rotating shaft 21 to rotate, so that the edge brushing part 22 brushes the edge of the pole plate, which has good practicability. The driving device 4 is a motor , the motor is connected to the rotating shaft 21 through a pulley transmiss...

Embodiment 2

[0016] The edge brushing device of the electrode plate edge brushing machine as described in Embodiment 1 has the following differences: the cylinder drives the movable seat to move back and forth along the horizontal centerline of the frame, which is convenient for edge edge brushing on the bottom of the electrode plate .

[0017] Place the pole plate on the frame 1, adjust the pulley tension between the motor and the brush edge assembly 2 through the tension pulley 5, and then drive the brush edge assembly 2 to rotate through the motor, so that the brush edge part of the brush edge assembly 2 can touch the pole plate For edge brushing, the movable plate is driven by the driving device 4 to move up and down or back and forth, so as to perform edge brushing on both sides or bottom of the polar plate.

[0018] The brush edge assembly is driven by the power device to brush the edge of the pole plate, and the brush edge assembly is driven by the driving device to reciprocate, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com