Full-automatic numerically-controlled machine tool for shafts

A CNC machine tool, fully automatic technology, applied in the field of machinery, can solve the problems of increasing the moving distance of the ejector rod, reducing work efficiency, and inaccurate positioning, so as to achieve the effect of shortening the moving distance, improving work efficiency, and avoiding inaccurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

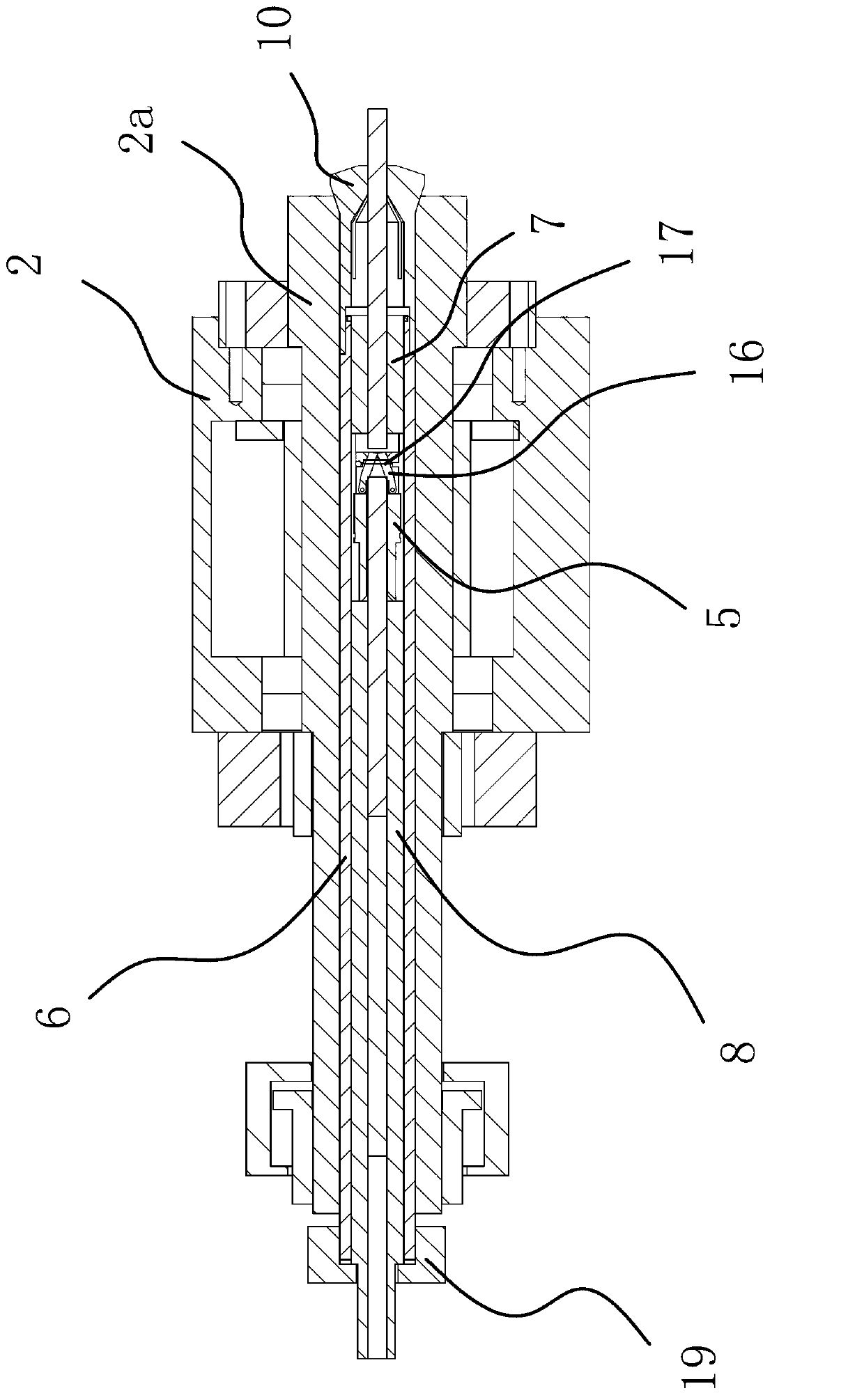

[0029] Such as figure 1 As mentioned above, this axis type fully automatic CNC machine tool includes a main frame 2 for processing shafts and having a main shaft 2a, and a front frame 22 and a rear frame 1 respectively arranged on both sides of the main frame 2 .

[0030] Front frame 22 upper side parts are equipped with and are used to place axle and the material box 12 that tilts to arrange, there is material delivery channel 14 on the front frame 22 and material box 12 outlets are communicated with material delivery channel 14, and there is delivery channel 14 on the front frame 22. The material channel 14 and the outlet of the material box 12 communicate with the material delivery channel 14, the outlet of the material box 12 communicates with the material delivery channel 14 and the height of the outlet of the material box 12 is slightly greater than the diameter of the shaft, which can ensure that the shaft enters the material delivery channel When inside 14, go in alone, ...

Embodiment 2

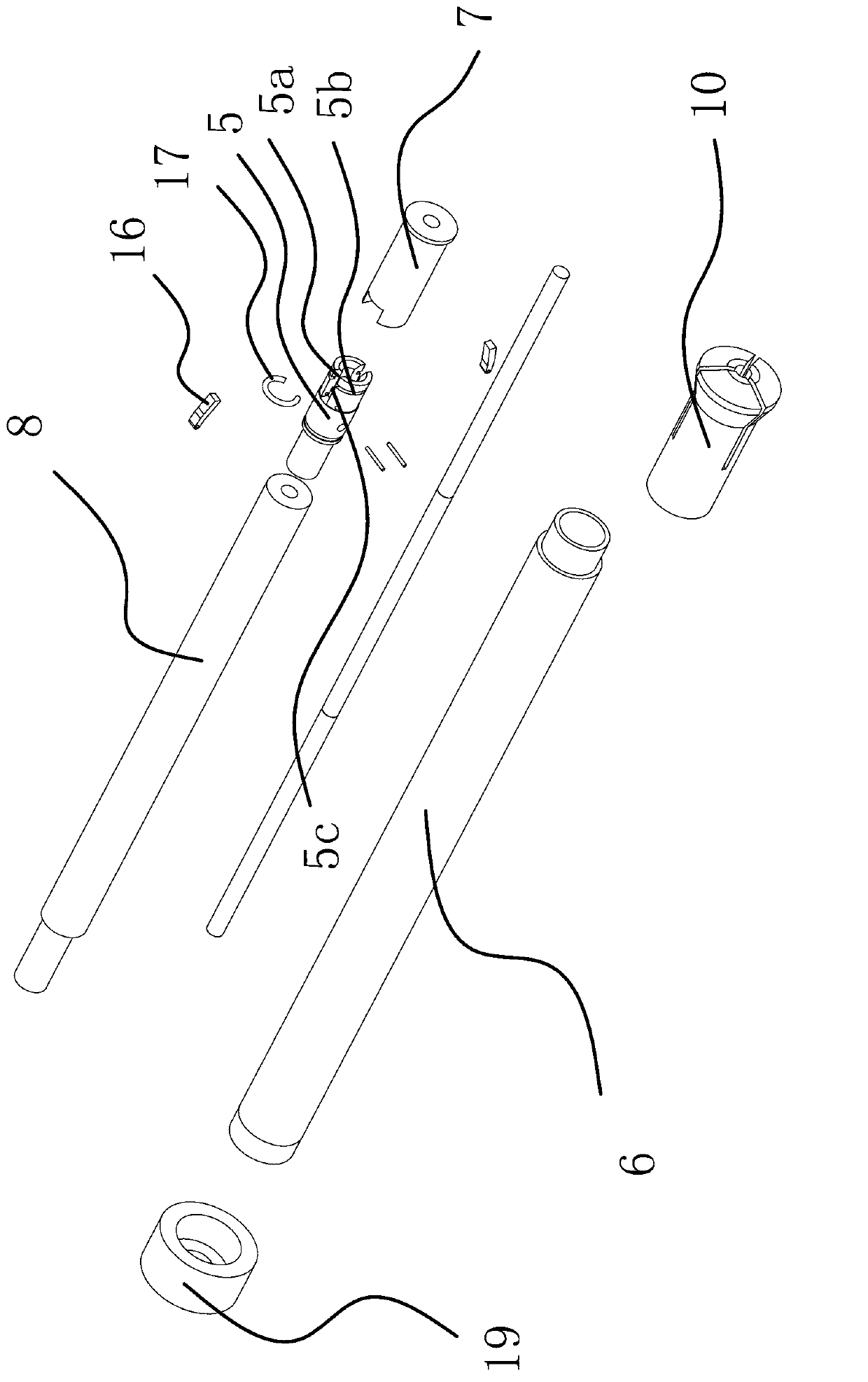

[0043] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 5 As shown, a strip-shaped installation hole 6a is opened on the outer wall of the clamping tube 6 in the axial direction, and bolts 21 for fixing the clamping tube 6 and the positioning seat 5 are inserted through the strip-shaped mounting hole 6a. This structure The front guide pipe 7 can be directly omitted, and since the distance between the front end of the collet 10 and the positioning seat 5 cannot be greater than the length of the shaft, the positioning seat 5 can be adjusted at any time according to the length of the shaft through the strip-shaped mounting hole 6a The installation position of the positioning seat 5 on the clamping tube 6 eliminates the need to replace the entire clamping tube 6, which is highly practical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com